Design of battery thermal management system

May 1, 2022 · This work documents the design of a battery thermal management system for an electric vehicle in which a side plate liquid cooling system was

Get Started

(PDF) Thermal Modelling of Battery Pack

Aug 16, 2023 · "Thermal Management of Lithium-Ion Battery Packs: Overview and Design Guidelines" by H. Wang, et al., in IEEE Transactions on

Get Started

Battery Thermal Management Systems of Electric Vehicles

Nov 25, 2022 · The battery thermal management system (BTMS) plays a vital role in the control of the battery thermal behaviour. The BTMS technologies are: air cooling system, liquid cooling

Get Started

(PDF) Implementing Six Sigma Principles to EV Battery Pack

Dec 20, 2024 · PDF | This project applied Six Sigma principles to improve the electric vehicle battery pack assembly process. Using the DMAIC framework (Define,... | Find, read and cite

Get Started

Modeling, Development, and Validation of Battery Management

5 days ago · The market of electric vehicles (EVs) is growing day by day due to their environmentally friendly operation. The Battery Management Systems (BMS) is the heart of

Get Started

battery-management-system · GitHub Topics ·

Jul 25, 2025 · go linux bash golang utility battery-level battery utilities systemd utils linux-kernel battery-life battery-monitor asus sh battery-management

Get Started

Battery Management System For Automotive

Jul 12, 2020 · Conclusion This project demonstrates a novel battery management system which actively monitors the critical parameters like voltage, capacity

Get Started

What Is a Battery Management System (BMS)?

4 days ago · A battery management system directly influences the safety, efficiency, and longevity of the battery, and by extension, the overall

Get Started

Top 10 Battery Management System Projects In Simulink

Jan 27, 2020 · To monitor and maintain the battery pack for proper usage, a BMS is needed. The main functions of BMS are. In BMS, you can select any topic as a project like cell balancing

Get Started

Battery Pack Thermal Design

Aug 17, 2016 · Minimize cell-to-cell temperature variations Prevent the battery from going above or below acceptable limits Maximize useful energy from cells and pack However, a battery

Get Started

Overview of batteries and battery management for electric

Nov 1, 2022 · Advances in EV batteries and battery management interrelate with government policies and user experiences closely. This article reviews the evolutions and challenges of (i)

Get Started

DelftX: Battery Management Systems (BMS) and Pack Design

Aug 14, 2025 · Explore the vital role of Battery Management Systems (BMS) in ensuring the performance, safety, and longevity of lithium-ion battery packs. This course is designed for

Get Started

A Comprehensive Review of Thermal

Feb 9, 2025 · The scientific aim of the study is to propose a comprehensive review of thermal management systems (TMSs) used in electric vehicle (EV)

Get Started

PowerPoint 演示文稿

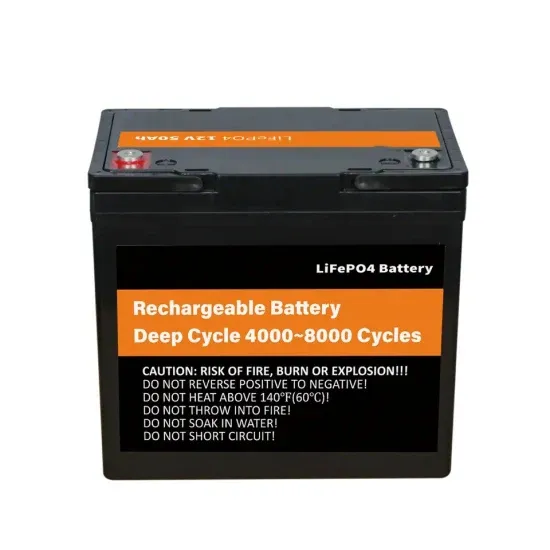

Feb 14, 2023 · Li-ion battery pack is a relatively mature technique to store renewable electricity, and it has already been widely used in both vehicles or power station. Even though Li-ion

Get Started

BATTERY MANAGEMENT SYSTEM A PROJECT REPORT

Aug 2, 2021 · battery which is occupying more capacity. A battery management system (BMS) is any electronic system that manages a rechargeable battery (cell or battery pack), such as by

Get Started

CFD and Thermal Analysis of Electric Vehicle Battery Pack

Aug 24, 2024 · Effective thermal management is imperative for maximizing battery lifespan and enhancing safety in Electric Vehicles (EVs). This study investigates the optimization of battery

Get Started

Battery Management Systems Design by Modelling

5 days ago · Explanation of the cover The cover shows a transparent battery as an illustration of the use of battery models for the design of Battery Management Systems.

Get Started

BATTERY MANAGEMENT SYSTEM A PROJECT REPORT

Aug 2, 2021 · BONAFIDE CERTIFICATE Certified that this project report "BATTERY MANAGEMENT SYSTEM" is the bonafide work of "DEEPIKA P, KARTHIKA K, NAVEENA S,

Get Started

Thermal Design of Battery Pack

This lesson covers the calculations involved in heat load and the active thermal management system. It further discusses passive thermal management, heat sinks, heat pipes, thermal

Get Started

Battery Mangement System (BMS) Project

Apr 26, 2025 · Battery mangement system (BMS) project report - Free download as Word Doc (.doc), PDF File (.pdf), Text File (.txt) or read online for free. The

Get Started

Review of battery thermal management systems in electric

Mar 1, 2024 · Lithium-ion batteries are the most commonly used battery type in commercial electric vehicles due to their high energy densities and ability to be repeatedly charged and

Get Started

(PDF) Cell Balancing in Electric Vehicle Battery

May 7, 2022 · This ensures the optimum performance of the Battery pack by not allowing any cell to overcharge or over-discharge hence, increasing its life and

Get Started

Battery Management System Design

The battery model consists of 12s3p cells, with three cells arranged in parallel and 12 cells arranged in series. To create a battery pack, refer to BatteryPackDesignScript.mlx or use the

Get Started

DESIGNING AND THERMAL ANALYSIS OF EV BATTERY

May 17, 2022 · An Autonomous Institution Affiliated to Anna University, Chennai - 600 025 BONAFIDE CERTIFICATE Certified that 16AUL81 Project "DESIGNING AND THERMAL

Get Started

Design and Simulation of Battery Management System for

Apr 18, 2024 · The Battery Management System (BMS) is a critical component in Electric Vehicles (EVs) that ensures the safe and optimal performance of the battery pack. Lead Acid Batteries

Get Started

An effective passive cell balancing technique for lithium-ion battery

Jul 1, 2025 · The increasing demand for clean transportation has propelled research and development in electric vehicles (EVs), with a crucial focus on enhancing battery technologies.

Get Started

What Is a Battery Management System (BMS)?

6 days ago · A battery management system directly influences the safety, efficiency, and longevity of the battery, and by extension, the overall

Get Started

An Approach for Designing Thermal Management

Oct 7, 2013 · ABSTRACT If battery packs for electric vehicles (EVs) and hybrid electric vehicles (HEVs) are to operate effectively in all climates, thermal management of the packs is essential.

Get Started

6 FAQs about [Battery PACK Project Management]

What are the best battery management system projects?

In BMS, you can select any topic as a project like cell balancing topologies, SoC estimation, converters, electric dynamics, etc. Well guys, now I will share some top 10 best battery management system projects. 10. Passive Cell Balancing Using 6 Lithium-Ion Cells

What is a battery pack management system (BMS) course?

This course is designed for engineers, researchers, and technical professionals seeking in-depth knowledge of battery technology and pack management systems. Comprehensive coverage: Delve into the key functions of BMS for battery packs, including protection, optimization, and monitoring of the state of battery.

What is battery management systems (BMS)?

Explore the vital role of Battery Management Systems (BMS) in ensuring the performance, safety, and longevity of lithium-ion battery packs. This course is designed for engineers, researchers, and technical professionals seeking in-depth knowledge of battery technology and pack management systems.

What is a battery pack model?

The battery pack consists of two battery modules, which are combinations of cells in series and parallel. You will learn how to train, validate, deploy a neural network to predict Battery Pack temperature. Battery pack model for thermal management tasks, with modules of cells in series and parallel.

How a battery management system works?

sults of investments in electric vehicles.The state of charge of batteries during a battery management system is just like the fuel meter during a conventional fuel car. The main function of the SoC is to speak the instinctive battery state to the driving force and at an equivalent time, avoid p

What makes a good battery pack?

Designing a reliable, safe and efficient battery pack isn’t just about selecting the right cells or managing heat, it’s about integrating every subsystem into a cohesive, validated system.

Related Articles

-

Pack battery project construction schedule

Pack battery project construction schedule

-

Kenya pack lithium battery project

Kenya pack lithium battery project

-

Lithium battery pack quality inspection items

Lithium battery pack quality inspection items

-

Rabat good lithium battery pack factory price

Rabat good lithium battery pack factory price

-

3 7V rechargeable lithium battery pack

3 7V rechargeable lithium battery pack

-

Judging the quality of lithium battery pack cells

Judging the quality of lithium battery pack cells

-

Bolivia pack battery factory

Bolivia pack battery factory

-

Powerful lithium battery management system bms

Powerful lithium battery management system bms

-

Tunisia battery pack factory

Tunisia battery pack factory

-

BMS battery management system assembly

BMS battery management system assembly

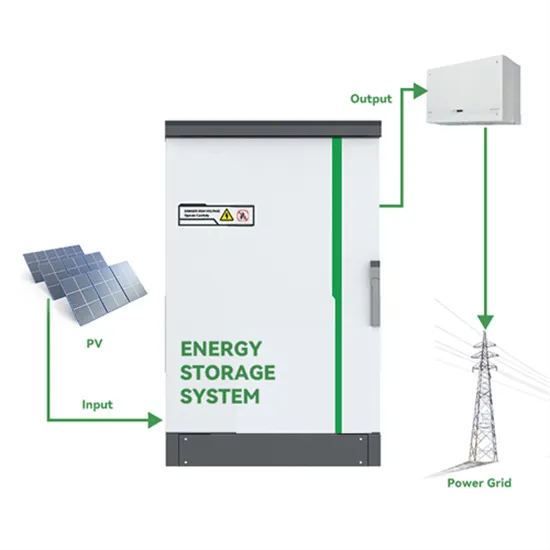

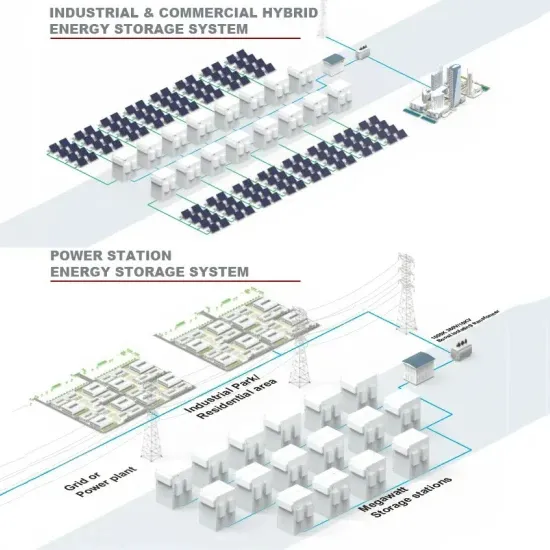

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.