The choices of simplified thermal boundary-conditions for

Feb 1, 2025 · The present work investigates the simplified boundary conditions (constant temperature and constant heat-flux), in accordance with the conjugate heat-transfer

Get Started

Research on Mechanical Simulation Model and Working Safety Boundary

Mar 24, 2022 · Abstract. The application of large-capacity automotive power batteries puts forward higher requirements on the safety test and evaluation technology. In this study, a

Get Started

Design and Simulation of a Lithium-ion Battery at Large

Jan 12, 2018 · In this paper, the heat flux distributions on a prismatic lithium-ion battery at 1C, 2C, 3C and 4C discharge rates under various operating temperature or boundary conditions (BCs)

Get Started

Numerical investigation on the thermal behavior of cylindrical lithium

Dec 15, 2022 · In this paper, a one-dimensional electrochemical model and a three-dimensional axisymmetric heat transfer model are coupled to simulate the electrochemical and thermal

Get Started

Thermo-electric modeling and analysis of lithium-ion battery

Apr 26, 2024 · In this work, active BTMS solutions are selected and analyzed using the development of three-dimensional free, open-source OpenFOAM computational fluid dynamics

Get Started

Thermal analysis of a cylindrical lithium-ion battery

Jan 1, 2011 · This work investigates the heat generation characteristics of a cylindrical lithium-ion battery. The battery consists of the graphite, LiPF 6 of the propylene carbonate/ethylene

Get Started

Real-Time Estimation of Temperature Distribution for Cylindrical

Nov 3, 2016 · This paper presents a real-time estimation method for the temperature distribution of cylindrical batteries under boundary air cooling. A space-/time-separation-based analytical

Get Started

Research on Mechanical Simulation Model and Working

Oct 5, 2023 · Wierzbicki and Sahraei [14] carried out experiments and simulations of at extrusion abuse of fl cylindrical batteries and extracted the average mechanical response of cylindrical

Get Started

An investigation on thermal runaway behaviour of a cylindrical lithium

Feb 15, 2023 · A significant risk for lithium-ion batteries (LIBs) is fire and explosions caused by thermal runaway (TR). A TR model for LIBs with various states of charge (SOCs) can help

Get Started

An online temperature estimation for cylindrical lithium-ion batteries

Nov 1, 2022 · To address this issue, this paper proposes a simplified distributed electrical-thermal model of the cylindrical lithium-ion battery to realize the online temperature estimation.

Get Started

Thermal Behavior Modeling of Lithium-Ion

Aug 17, 2023 · To enhance our understanding of the thermal characteristics of lithium-ion batteries and gain valuable insights into the thermal impacts of

Get Started

Design, Properties, and Manufacturing of Cylindrical Li-Ion

Jun 3, 2023 · This paper investigates 19 Li-ion cylindrical battery cells from four cell manufacturers in four formats (18650, 20700, 21700, and 4680). We aim to systematically capture the design

Get Started

Dynamic response analysis of cylindrical lithium-ion battery

Dec 1, 2024 · The prediction of serious deformation for lithium-ion batteries (LIBs) under impact loadings becomes an important challenge for engineering application. In this paper, a

Get Started

A Comprehensive Guide to Cylindrical Lithium

Jul 31, 2025 · The story of cylindrical lithium-ion battery cells traces back to the 1990s, when researchers pioneered the development of rechargeable lithium

Get Started

Thermal Modeling of a Cylindrical Lithium-Ion Battery in

Dec 13, 2022 · Introduction This example simulates an air-cooled cylindrical 18,650 lithium-ion battery in 3D. A one-dimensional cell model is used to model the battery cell chemistry, and a

Get Started

Core collapse in cylindrical Li-ion batteries

Dec 15, 2024 · The phenomena of core collapse observed in cylindrical lithium-ion batteries offer valuable insights that apply to other battery formats by revealing fundamental principles of

Get Started

Illustration of cross section of the cylindrical

We present a one-dimensional, radial, coupled degradation-electrochemical-thermal (DET) model of a large format cylindrical lithium ion cell. The model

Get Started

Thermal and Heat Transfer Modeling of Lithium Ion

Dec 8, 2020 · The Lithium-ion (Li-ion) battery is considered as the first – choice candidate for a power source of EVs and HEVs due to its many advantages such as low self-discharge rate,

Get Started

The choices of simplified thermal boundary-conditions for

Feb 1, 2025 · Computational fluid dynamics-based numerical analysis for studying the effect of mini-channel cooling plate, flow characteristics, and battery arrangement for cylindrical lithium

Get Started

Mechanical Behavior and Failure Prediction of Cylindrical Lithium

Dec 16, 2024 · Abstract. Mechanical failure prediction of lithium-ion batteries (LIBs) can provide important maintenance information and decision-making reference in battery safety

Get Started

Research on Mechanical Simulation Model and

Mar 11, 2022 · This research provides an effective and practical procedure to judge the safety of lithium-ion batteries after collisions and can be extended to

Get Started

Cell types used for jelly-roll gap analysis.

Download scientific diagram | Cell types used for jelly-roll gap analysis. from publication: Influence of Breathing and Swelling on the Jelly-Roll Case Gap of

Get Started

Performance study on a novel hybrid thermal management

Jul 15, 2025 · High energy density cylindrical lithium-ion battery packs face severe thermal challenges under high intensity discharge conditions, which significantly reduce the

Get Started

Application of boundary conditions on the

Download scientific diagram | Application of boundary conditions on the cylindrical 18650 lithium-ion battery from publication: A Simulation-based Probabilistic

Get Started

Thermal evaluation of lithium-ion batteries: Defining the cylindrical

Oct 1, 2022 · Managing temperatures of lithium-ion cells in battery packs is crucial to ensuring their safe operation. However, thermal information provided on typi

Get Started

Research on Mechanical Simulation Model and Working

Jan 2, 2024 · Wierzbicki and Sahraei [14] carried out experiments and simulations of at extrusion abuse of fl cylindrical batteries and extracted the average mechanical response of cylindrical

Get Started

Investigating thermal dynamics in cylindrical Li-ion

5 days ago · Thermal dynamics in cylindrical Li-ion batteries, governed by electrochemical heat generation, are critical to performance and safety in high-power applications such as electric

Get Started

Thermo-electric modeling and analysis of lithium-ion battery

Apr 26, 2024 · This study considered the cylindrical cell battery pack, examined the transient thermal behavior of cylindrical Li-ion battery modules when cooled by forced air, and

Get Started

Enhancing thermal performance of cylindrical Li-ion battery

Aug 1, 2024 · This study conducts a three-dimensional simulation of the temperature of a cylindrical Li-ion battery (LIB) pack with nine cells. The cells are arrang

Get Started

Boundary control synthesis for a lithium‐ion

Jun 27, 2013 · The thermal regulation problem for a lithium ion (Li-ion) battery with boundary control actuation is considered. The model of the transient

Get Started

Optimal cell tab design and cooling strategy for cylindrical lithium

Apr 30, 2021 · The ability to correctly predict the behavior of lithium ion batteries is critical for safety, performance, cost and lifetime. Particularly important for this purpose is the prediction

Get Started

Application of boundary conditions on the

Download scientific diagram | Application of boundary conditions on the cylindrical 18,650 lithium-ion battery from publication: Crash analysis of lithium-ion

Get Started

Comprehensive review of multi-scale Lithium-ion batteries

Feb 1, 2025 · This review integrates the state-of-the-art in lithium-ion battery modeling, covering various scales, from particle-level simulations to pack-level thermal management systems,

Get Started

Stress-Diffusion Analysis of Electrode Particles

Dec 31, 2024 · A mechano-electrochemical model is proposed to study diffusion-induced stresses (DISs) in the electrode particles with three different shapes.

Get Started

6 FAQs about [Boundary of cylindrical lithium battery]

What is a cylindrical lithium ion battery?

Cylindrical lithium-ion battery cells are a type of rechargeable battery commonly used in a wide range of electronic devices, electric vehicles, and energy storage systems. They are characterized by their cylindrical shape, standardized sizes, and high energy density, making them versatile and suitable for various applications.

How do you identify a cylindrical lithium-ion battery?

For instance, “65” represents a height of 65mm. Fifth Digit: The fifth digit indicates the cylindrical shape of the cell. Typically, it’s “0” for cylindrical cells. By following this naming convention, we can easily identify the size and shape of cylindrical lithium-ion battery cells.

How many Li-ion cylindrical battery cells are there?

This paper investigates 19 Li-ion cylindrical battery cells from four cell manufacturers in four formats (18650, 20700, 21700, and 4680). We aim to systematically capture the design features, such as tab design and quality parameters, such as manufacturing tolerances and generically describe cylindrical cells.

How to design cylindrical Li-ion battery cells?

A generic overview of designing cylindrical Li-ion battery cells. Function 1: Two types of jelly roll designs can be distinguished: With tabs and tabless. Jelly rolls with tabs can be realized with a single tab (Design A) or several tabs in a multi-tab design (Design B).

What are the naming rules for lithium ion batteries?

The naming rules for cylindrical lithium-ion battery cells follows a standardized format based on the cell’s dimensions, and usually represented by a five-digit code, where each digit provides specific information about the cell’s dimensions. Here’s a breakdown of the representation: What does 18650 means?

What is a cylinder Li-ion battery?

Cylindrical Li-ion battery cells consist of (i) a jelly roll, a wound composite consisting of a cathode, an anode, and two separators, and (ii) a cell housing consisting of a can and a cap . Current and heat transport between the jelly roll and the cell housing is traditionally conducted by contacting elements called tabs .

Related Articles

-

26500 cylindrical lithium battery

26500 cylindrical lithium battery

-

Cylindrical lithium battery automatic charging equipment

Cylindrical lithium battery automatic charging equipment

-

Lithium battery wholesale cylindrical

Lithium battery wholesale cylindrical

-

Italian Milan cylindrical lithium battery millivolt

Italian Milan cylindrical lithium battery millivolt

-

Lithium Cylindrical Battery

Lithium Cylindrical Battery

-

Azerbaijan cylindrical lithium battery customization

Azerbaijan cylindrical lithium battery customization

-

Cylindrical lithium battery production battery pack

Cylindrical lithium battery production battery pack

-

Cost-effective cylindrical lithium battery

Cost-effective cylindrical lithium battery

-

4V 2600mh cylindrical lithium battery price

4V 2600mh cylindrical lithium battery price

-

Roman cylindrical lithium battery price

Roman cylindrical lithium battery price

Commercial & Industrial Solar Storage Market Growth

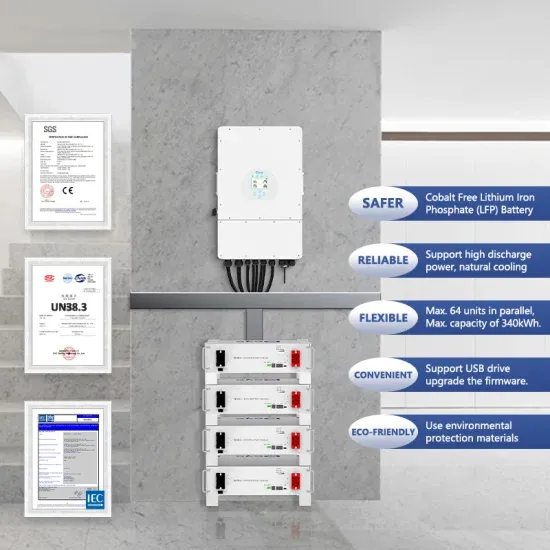

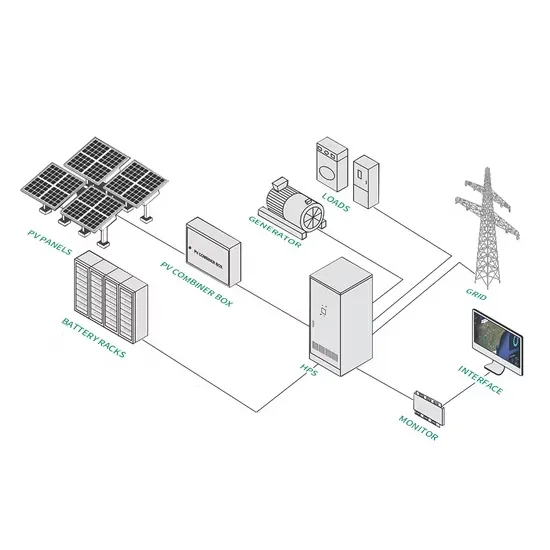

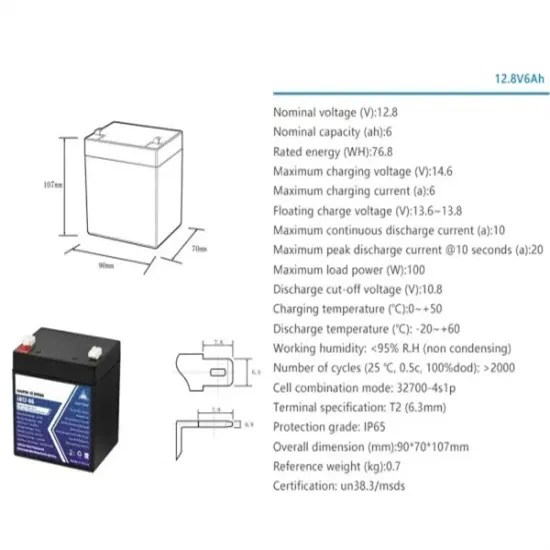

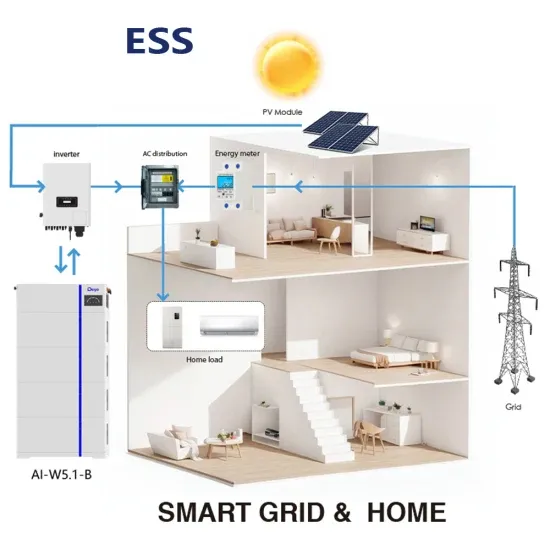

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.