The production of lithium-ion cells

Jan 25, 2023 · Correct assembly of the cells that make up a lithium battery, whether such cells are prismatic, cylindrical or of the pouch type, is therefore

Get Started

Layout and expansion of 46 series cylindrical

Jul 18, 2022 · Layout and expansion of 46 series cylindrical large cells Samsung SDI, a battery supplier under Samsung, is also developing 4680 batteries, but

Get Started

Bcya-L02f Automatic Assembly Line for Big Cylindrical Lithium Battery

Jul 1, 2025 · Bcya-L02f Automatic Assembly Line for Big Cylindrical Lithium Battery Packs, Find Details and Price about Automatic Assembly Line Big Cylindrical Lithium Battery Packs from

Get Started

Large cylindrical lithium ion battery module pack production

May 21, 2025 · What is Large cylindrical lithium ion battery module pack automatic production line ? The battery pack assembly line is the heart of the battery manufacturing process.

Get Started

Large Cylindrical Lithium Battery PACK Assembly Line

We''re Professional Battery Pack Assembly Line Solutions Manufacturer.We Offer Customized Battery Pack Assembly Lines Solution With Competitive Price,Good Service for You.

Get Started

Lithium Ion Battery Assembly Process and Line: Cylindrical vs

Aug 20, 2024 · Prismatic cells, known for their rectangular shape, are favored in applications requiring space efficiency and higher energy density, such as electric vehicles and large-scale

Get Started

KNOWLEDGE PAPER ON LITHIUM-ION BATTERY

Jan 22, 2024 · Diferent shapes of the lithium-ion cell Nomenclature of lithium-ion cell/battery Overview of Li-ion battery packs Assembling Process Detailed flowchart for Li-ion battery pack

Get Started

Cylindrical Lithium Battery Production Line: Fully Automated

Discover our advanced cylindrical lithium battery production line designed for manufacturing 18650, 21700, and other cylindrical battery models. Our fully automated equipment covers

Get Started

Why EVE believe in Large Cylindrical Cells

Apr 1, 2025 · Large cylindrical batteries feature a steel casing with 550MPa strength—5.5 times that of prismatic aluminum casings (95MPa). Combined

Get Started

Large Cylindrical Lithium Battery PACK Assembly Line Cylindrical

Sample Solutions as below: Device Name: Lithium Battery PACK Production Line Equipment size: 17000 (length) × 1500 (width) × 1900 (height) mm Device Functions: 1: production bus

Get Started

Battery Module: Manufacturing, Assembly and

Dec 28, 2022 · In the Previous article, we saw the first three parts of the Battery Pack Manufacturing process: Electrode Manufacturing, Cell Assembly, Cell

Get Started

Automated Li-ion Battery Assembly Machines | SZJ Automation

Automated cell assembly lines for cylindrical batteries provide the most efficient and precise solution for cell manufacturing. A complete cylindrical cell automated assembly line includes

Get Started

Comprehensive Guide to Battery Assembly

Jun 18, 2024 · Part 2. Types of lithium batteries Lithium-ion Batteries Composition: Lithium-ion batteries (Li-ion) use lithium compounds as

Get Started

Large Cylindrical Battery Assembly – Automated Precision

Our automated systems are optimized for the high-volume production of large cylindrical battery cells. From alignment to welding, every step is designed for accuracy, speed, and consistency.

Get Started

Cylindrical Cell Assembly Line

Oct 8, 2024 · A cylindrical cell assembly line is a highly automated production system designed to manufacture cylindrical battery cells,commonly used in applications such as electric vehicles

Get Started

Understanding the Battery Cell Assembly Process

Nov 11, 2023 · The production process of a lithium-ion battery cell consists of three critical stages: electrode manufacturing, cell assembly, and cell finishing.

Get Started

Cylindrical Cell manufacturing line

Apr 11, 2025 · A Cylindrical Cell Manufacturing Line is an advanced industrial setup designed to mass-produce cylindrical lithium-ion batteries. It combines specialized machinery, automation

Get Started

Bcya-B05eautomatic Assembly Line for Big Cylindrical Lithium Battery

Jul 1, 2025 · Bcya-B05eautomatic Assembly Line for Big Cylindrical Lithium Battery Packs, Find Details and Price about Automatic Assembly Line Big Cylindrical Lithium Battery Packs from

Get Started

Battery Production Flyer: Lithion Ion Cell Production

Feb 7, 2024 · Electrode manufacturing Cell assembly Cell finishing The manufacture of the lithium-ion battery cell comprises the three main process steps of electrode manufacturing, cell

Get Started

Exploring Assembly and Testing of Cylindrical

Nov 15, 2024 · Explore the assembly and testing of cylindrical batteries, their unique design, applications, and advantages in energy storage and electric

Get Started

How to enable large format 4680 cylindrical lithium-ion batteries

Nov 1, 2023 · The demand for large format lithium-ion batteries is increasing, because they can be integrated and controlled easier at a system level. However, increasing the size leads to

Get Started

18650 Battery Production Machine,Cylindrical

LiFePO4 Lithium Cylindrical Battery Pack Assembly Equipment Machine Line Fully Automatic Lithium-Ion Cylindrical Cell Production Line For All Types

Get Started

Cylindrical Lithium Battery Production Line: Fully Automated

The cylindrical lithium battery production line is designed for manufacturing 18650, 21700, and other models of cylindrical lithium-ion batteries. This production line covers the entire process

Get Started

High Safety, High Cost-Effectiveness: Cham New Energy

Aug 23, 2024 · Cham New Energy''s large cylindrical batteries feature full-tab technology, which significantly reduces internal resistance and heat generation, leading to a 90% reduction in

Get Started

Optimization of fast-charging strategy for LISHEN 4695 cylindrical

Feb 15, 2025 · Abstract Developing fast-charging technology for lithium-ion batteries with high energy density remains a significant and unresolved challenge. Fortunately, the advent of the

Get Started

American Lithium Battery Manufacturing

Our process begins with custom-configured assembly lines designed around your product. We use robotics, real-time monitoring, and in-line testing to build

Get Started

How Lithium-Ion Cell Sizes Impact Performance and Usability

Jun 21, 2025 · Part 1: Lithium Ion Cell Sizes – A Comprehensive Guide 1.1 Common Formats: Cylindrical, Prismatic, and Pouch Cells Lithium-ion cells come in three primary formats, each

Get Started

LiFePO4 Cells Pack Assembly Line

Sep 13, 2024 · LiFePO4 Cells Pack Assembly Line: Optimizing the Manufacturing Process for Lithium Iron Phosphate Batteries As demand for safer, more efficient, and durable energy

Get Started

Large Cylindrical Battery Expand Ten Times More

May 22, 2025 · The fact that the volume change of large cylindrical battery far exceeds that of small cylindrical battery, with a difference exceeding tenfold.

Get Started

(PDF) BATTERY MODULE AND PACK ASSEMBLY

Feb 6, 2019 · Our second brochure on the subject "Assembly process of a battery module and battery pack" deals with both battery module assembly and

Get Started

Analysis of cylindrical lithium battery advantages

Feb 6, 2023 · Cylindrical lithium battery is a kind of lithium ion battery, its shape is cylindrical, so it is called cylindrical lithium battery.

Get Started

Tesla''s 4680 Battery and the Industry''s Competitive Landscape

Aug 8, 2024 · On the other hand, as large cylindrical products reach full-scale production across the supply chain and mature battery recycling forms a closed loop, industry estimates suggest

Get Started

6 FAQs about [Large cylindrical lithium battery assembly]

What is a large cylindrical battery?

Large cylindrical batteries feature a steel casing with 550MPa strength—5.5 times that of prismatic aluminum casings (95MPa). Combined with a 1500MPa dual-layer hot-formed steel bottom design and 3500MPa aerospace-grade fiberglass, they achieve crash energy absorption of 1000J—6.6 times the national standard.

What is a cylindrical lithium-ion battery?

A cylindrical lithium-ion battery is a type of lithium-ion battery with a cylindrical shape using a metal can as its packaging material.

What is a cylinder type lithium ion secondary battery?

Cylindrical Type Lithium Ion Secondary Batteries are packaged in metal cans. These batteries can be used at high rate and maintain high capacity. If you cannot find the model number, post to the Contact Form.

How efficient are large cylindrical batteries at 300 ppm?

Here, we can see that the manufacturing efficiency of large cylindrical batteries at 300 PPM is 10 times that of prismatic cells, while our manufacturing steps have been further reduced to 10 steps, shortening the production cycle to 7 days.

Why do large cylindrical batteries have a circular geometry?

The circular geometry of large cylindrical batteries ensures uniform stress distribution from the beginning to the end of their lifecycle, eliminating axial swelling entirely.

What is the difference between a prismatic and a cylindrical battery?

Compared to prismatic cells, the zero-swelling characteristic of large cylindrical batteries guarantees consistent performance throughout the entire lifecycle, rendering stress management obsolete. Drive with Confidence

Related Articles

-

Large cylindrical 10ah lithium battery

Large cylindrical 10ah lithium battery

-

Large cylindrical lithium battery all sizes

Large cylindrical lithium battery all sizes

-

Large lithium battery energy storage assembly plant

Large lithium battery energy storage assembly plant

-

Colombia cylindrical lithium battery equipment

Colombia cylindrical lithium battery equipment

-

Cylindrical lithium battery expansion

Cylindrical lithium battery expansion

-

Azerbaijan cylindrical lithium battery customization

Azerbaijan cylindrical lithium battery customization

-

28cm cylindrical lithium battery

28cm cylindrical lithium battery

-

Cylindrical lithium battery into the box

Cylindrical lithium battery into the box

-

Cylindrical lithium battery automatic charging equipment

Cylindrical lithium battery automatic charging equipment

-

Lithium battery wholesale cylindrical

Lithium battery wholesale cylindrical

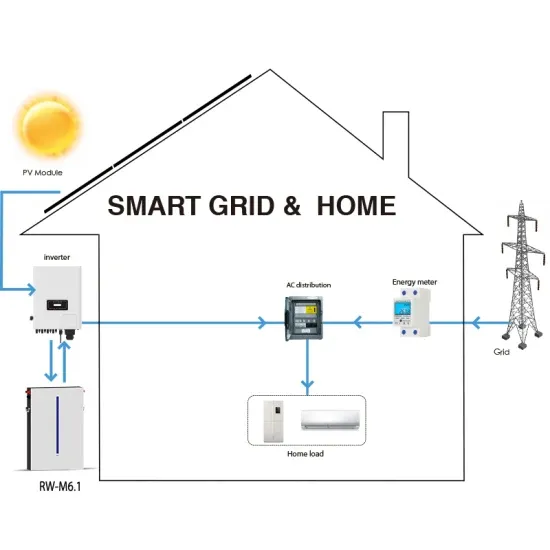

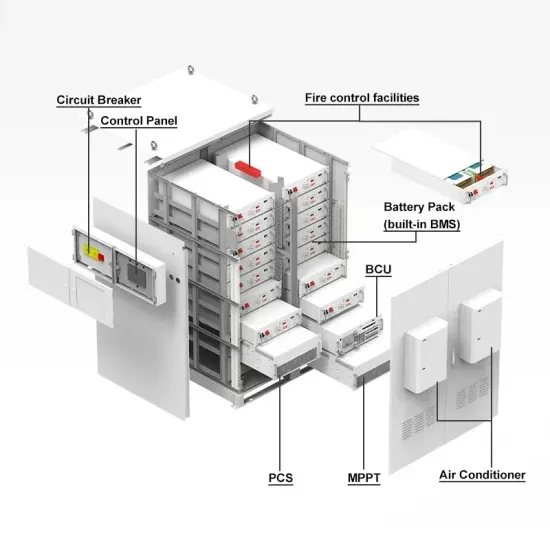

Commercial & Industrial Solar Storage Market Growth

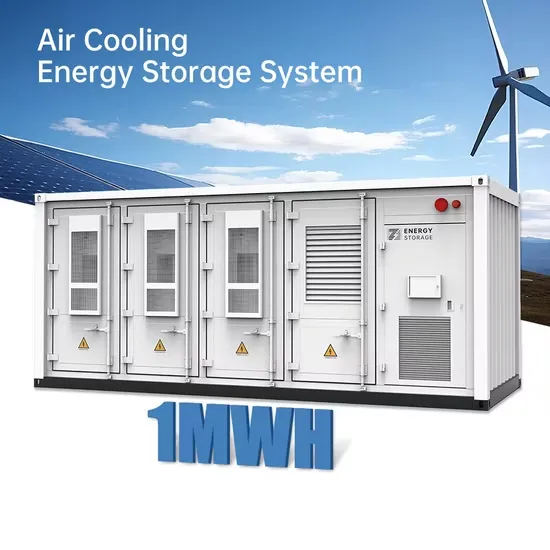

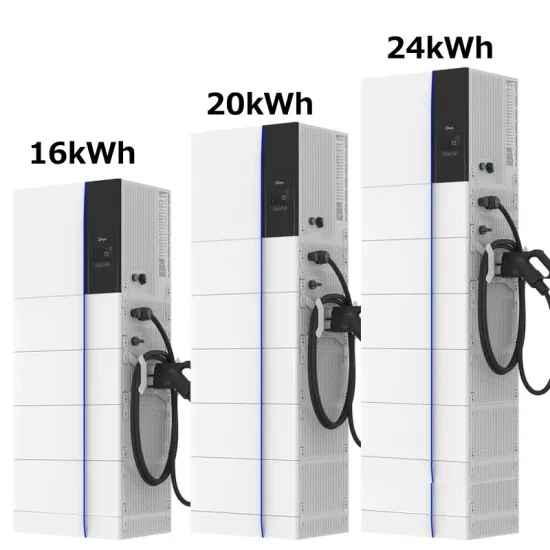

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.