Improvement of Zinc-Cerium Redox Flow Batteries Using

Thus, employing mixed methanesulfonate-chloride electrolytes in the negative half-cell of a zinc-cerium RFBs both extends the battery life-cycle and enhances the CE and VE e ciencies

Get Started

The Development of Zn–Ce Hybrid Redox Flow

Nov 13, 2014 · The Zn–Ce flow battery is a recently introduced hybrid redox flow battery (RFB) but has been extensively studied in the laboratory and at the

Get Started

A two-dimensional transient model for a zinc-cerium redox flow battery

Sep 15, 2021 · A two-dimensional transient model accounting for the charge, mass and momentum transport coupled with electrode kinetics is developed for zinc-cerium redox flow

Get Started

Improving performance of hybrid Zn–Ce redox flow battery

Sep 4, 2024 · For the conditions considered in this study, as much as 36% of the initial Zn (II) ions transferred from the negative to the positive electrolyte and 42.5% of the H + in the positive

Get Started

A high-performance aqueous Eu/Ce redox flow battery for

Nov 15, 2024 · Unlike zinc-cerium flow battery, the active species of Eu/Ce flow battery are always present in the electrolyte, and no liquid-solid phase transition occurs. Thus, Eu/Ce flow battery

Get Started

Colourful Chemistry – from Hybrid Flow Batteries

Jul 2, 2012 · In comparison, the hybrid flow battery based on zinc/iron in combination with salicylic acid worked exactly like the one just explained

Get Started

Zinc-Cerium Redox Flow Batteries: A Deep Dive

Jun 9, 2025 · The battery consists of two electrodes separated by a membrane, with the electrolytes pumped through the electrodes during charging and discharging. The Zinc-Cerium

Get Started

The Renaissance of the Zn-Ce Flow Battery: Dual

Sep 19, 2022 · While the zinc–cerium flow battery has the merits of low cost, fast reaction kinetics, and high cell voltage, its potential has been restricted due to

Get Started

Flow Battery

Flow batteries are defined as a type of battery that combines features of conventional batteries and fuel cells, utilizing separate tanks to store the chemical reactants and products, which are

Get Started

In situ polarization study of zinc–cerium redox flow batteries

Sep 30, 2020 · An in situ investigation of the sources of performance loss during discharge of a zinc-cerium redox flow battery (RFB) has been carried out. Polarizat

Get Started

Zinc-based flow batteries for medium

Jan 1, 2015 · In a typical Zn-Br 2 battery, the electrolyte containing zinc ions normally includes additives and flows by the electrode, usually carbon, in order to avoid the formation of zinc

Get Started

Zinc–Cerium and Related Cerium‐Based Flow Batteries:

Nov 1, 2022 · The life-cycle of a zinc-cerium redox flow battery (RFB) is investigated in detail by in situ monitoring of the half-cell electrode potentials and measurement of the Ce (IV) and H+

Get Started

The developments and challenges of cerium half-cell in

Jan 3, 2020 · Performance of zinc–cerium & ferrum redox flow cell is better than that of zinc–cerium & nitroso redox flow cell at large charge–discharge current. As shown in Fig. 5,

Get Started

Excellent stability and electrochemical performance of the electrolyte

Feb 1, 2021 · Nikiforidis studied the negative electrode reaction in the zinc-cerium flow battery with an indium modified graphite electrode aiming to suppress the competing HER and it was found

Get Started

A high-rate and long-life zinc-bromine flow battery

Sep 1, 2024 · Abstract Zinc-bromine flow batteries (ZBFBs) offer great potential for large-scale energy storage owing to the inherent high energy density and low cost. However, practical

Get Started

Use of Mixed Methanesulfonic Acid/Sulfuric Acid

Feb 28, 2023 · The effect of different positive supporting electrolytes on the performance of a bench-scale Zn-Ce redox flow battery (RFB) has been

Get Started

High-voltage and dendrite-free zinc-iodine flow

Jul 24, 2024 · Researchers reported a 1.6 V dendrite-free zinc-iodine flow battery using a chelated Zn(PPi)26- negolyte. The battery demonstrated stable

Get Started

Investigations on new Fe–Mn redox couple based aqueous redox flow battery

Jun 10, 2020 · A new class of redox flow batteries involving Fe3+ /Fe 2+ and Mn 3+ /Mn 2+ redox couples in the anolyte and catholyte, respectively being investigated. The proposed novel

Get Started

Characterization of a zinc–cerium flow battery

Jun 1, 2011 · The performance of a cerium–zinc redox flow battery in methanesulfonic acid was evaluated under: different electrode materials, electrolyte compositions and life-cycle testing.

Get Started

Zinc-based flow batteries for medium

Jan 1, 2015 · This chapter reviews three types of redox flow batteries using zinc negative electrodes, namely, the zinc-bromine flow battery, zinc-cerium flow battery, and zinc-air flow

Get Started

Zinc-cerium redox flow battery for renewable energy storage

Oct 7, 2022 · Scientists in Hong Kong have designed a redox flow battery with electrolytes made of zinc and cerium. They claim to have solved the incompatibility issue posed by these two

Get Started

Scientific issues of zinc‐bromine flow batteries

Jul 20, 2023 · Zinc-bromine flow batteries are a type of rechargeable battery that uses zinc and bromine in the electrolytes to store and release electrical

Get Started

Unlocking Zinc-Cerium Redox Battery Potential

Jun 9, 2025 · Discover the intricacies of Zinc-Cerium Redox Batteries, exploring their electrochemistry, advantages, and future prospects in energy storage.

Get Started

An undivided zinc–cerium redox flow battery operating at

Aug 1, 2011 · An undivided zinc–cerium hybrid redox flow battery is proposed. High discharge cell voltage of c.a. 2.1 V at 20 mA cm − 2 and an average energy efficiency of 75% were obtained.

Get Started

Improving performance of hybrid Zn–Ce redox flow battery

Sep 4, 2024 · In this study, the crossover of the electroactive species Zn(II), Ce(III), Ce(IV), and H+ across a Nafion 117 membrane was measured experimentally during the operation of a

Get Started

Life-Cycle Analysis of Zinc-Cerium Redox Flow Batteries

Oct 11, 2023 · At a current density of 25 mA cm 2, the charge e ciency of the battery is initially limited by the zinc redox reaction, which leads to the incomplete reduction of Ce(IV) to Ce(III)

Get Started

Introducing Cerium Based High Energy Redox Batteries

Jun 7, 2017 · The identification of methanesulfonic acid (MSA) as the best electrolyte for cerium is due to Kreh et al (1), the application of this to a electric storage batteries is novel. In this later

Get Started

Voltage Loss Analysis of Zinc-Cerium Redox Flow Batteries

Nov 23, 2020 · Thus, zinc-cerium RFBs are capable of providing one of the highest cell voltages (~ 2.4 V) among flow batteries and a large theoretical energy density [2]. To date, Zn-Ce RFBs

Get Started

Development and progress in Zn-Ce flow batteries are

Aug 18, 2025 · Introduction Redox flow batteries (RFBs) are one of the most viable technologies for larger scale energy lling in grid supply systems and have been the su reviews [1-4].

Get Started

Review of zinc-based hybrid flow batteries: From fundamentals

Jun 1, 2018 · Abstract Zinc-based hybrid flow batteries are one of the most promising systems for medium- to large-scale energy storage applications, with particular advantages in terms of

Get Started

Flow battery

A flow battery, or redox flow battery (after reduction–oxidation), is a type of rechargeable battery where rechargeability is provided by two chemical components dissolved in liquids contained

Get Started

Life-cycle analysis of zinc-cerium redox flow batteries

Oct 1, 2020 · In zinc-cerium RFBs, the redox reaction occurring on the negative side of the battery during charge phase is the deposition of zinc metal from a solution containing dissolved Zn (II),

Get Started

Improvement of zinc-cerium redox flow batteries using

Dec 1, 2019 · The performance of a zinc-cerium redox flow battery (RFB) with mixed methanesulfonate (MSA) – chloride negative electrolyte is compared to that of a zinc-cerium

Get Started

Impact of electrolyte composition on the performance of the zinc–cerium

Dec 1, 2013 · Abstract The zinc–cerium redox flow battery has the highest open circuit cell voltage (Ecell = 2.4 V) of all the common redox flow battery (RFB) systems being investigated. In this

Get Started

High performance and long cycle life neutral zinc-iron flow batteries

Jan 1, 2022 · Abstract Zinc-based flow batteries have attracted tremendous attention owing to their outstanding advantages of high theoretical gravimetric capacity, low electrochemical

Get Started

6 FAQs about [Total ions discharged from zinc-cerium flow battery]

Why is zinc-cerium flow battery a good choice?

While the zinc–cerium flow battery has the merits of low cost, fast reaction kinetics, and high cell voltage, its potential has been restricted due to unacceptable charge loss and unstable cycling performance, which stem from the incompatibility of the Ce and Zn electrolytes.

Can zinc-cerium redox flow battery be a positive half-cell electrolyte?

Cerium-zinc redox flow battery: positive half-cell electrolyte studies The developments and challenges of cerium half-cell in zinc-cerium redox flow battery for energy storage Electrochim. Acta, 90 ( 2013), pp. 695 - 704

How long does a zinc–cerium battery charge at 50 mA cm 2?

Life cycle of a zinc–cerium battery charging at 50 mA cm −2 for different lengths of time: (a) 15 min and (b) 4 h. Electrolyte compositions and operating conditions were the same as in Fig. 3. Fig. 9. Life cycle of a zinc–cerium battery charging at 50 mA cm −2 for 3 h followed by 15 min charge/discharge cycles.

Are anion exchange membranes important for zinc-cerium redox flow batteries?

This analysis revealed that the use of anion exchange membranes with extremely low proton leakage and high stability in the presence of Ce (IV) is key for the ultimate success of zinc-cerium redox flow batteries. Kiana Amini: Investigation, Methodology, Data curation, Writing - original draft.

How does a zinc-cerium battery work?

The zinc-cerium battery employs an acid electrolyte and the deposition/dissolution of zinc, and Reaction (8.1) is combined with the interconversion of Ce (III) and Ce (IV), Reaction (8.6), in the aqueous acid medium (8.6) Ce III − e − → discharge charge Ce IV

What is the cell reaction of a zinc redox flow battery?

SHE) The overall cell reaction of the zinc–cerium redox flow battery, taking the standard potential of reaction (3) as 1.44 vs. SHE, is: (5) 2 Ce (C H 3 S O 3) 3 + Zn (C H 3 S O 3) 2 ⇄ Discharge Charge Zn + Ce (C H 3 S O 3) 4 (E cell = 2.4 V)

Related Articles

-

Zinc flow battery effect

Zinc flow battery effect

-

Zinc oxygen flow battery

Zinc oxygen flow battery

-

Chrome iron flow battery volume

Chrome iron flow battery volume

-

Overall reaction of zinc-bromine flow battery

Overall reaction of zinc-bromine flow battery

-

Lithium iron phosphate battery flow battery

Lithium iron phosphate battery flow battery

-

Vanadium flow battery financingBESS

Vanadium flow battery financingBESS

-

Mogadishu Mobile Company Communication Base Station Flow Battery

Mogadishu Mobile Company Communication Base Station Flow Battery

-

Manila All-vanadium Liquid Flow Battery

Manila All-vanadium Liquid Flow Battery

-

All-vanadium liquid flow battery adapts to temperature

All-vanadium liquid flow battery adapts to temperature

-

Vanadium Carbon Liquid Flow Battery Field

Vanadium Carbon Liquid Flow Battery Field

Commercial & Industrial Solar Storage Market Growth

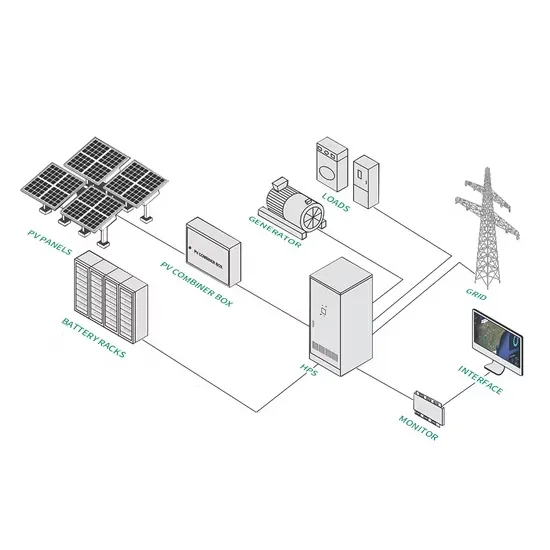

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.