Thin-Film Silicon Photovoltaics

This contribution reviews some of the latest achievements and challenges in thin-film silicon photovoltaic (PV) technology based on amorphous and nanocrystalline silicon and their alloys.

Get Started

US20100147364A1

The present invention provides module structures and methods of manufacturing rigid or flexible photovoltaic modules employing thin film solar cells fabricated on flexible substrates,

Get Started

Thin Films Photovoltaics

Feb 23, 2022 · Thin film photovoltaic-based solar modules produce power at a low cost per watt. They are ideal candidates for large-scale solar farms as well

Get Started

Thin-film solar cell | Definition, Types, & Facts

Thin-film solar cell, type of device that is designed to convert light energy into electrical energy (through the photovoltaic effect) and is composed of micron

Get Started

The next level for thin-film solar modules

Around 90 percent of the photovoltaic systems installed worldwide operate with solar cells made of crystalline silicon. Thin film modules have numerous

Get Started

Photovoltaic thin-film modules

Disadvantages of thin-film PV modules As already mentioned, the efficiency of the amorphous solar modules is significantly lower than that of other photovoltaic

Get Started

Mitsubishi Thin Film Photovoltaic Module

May 13, 2021 · The thin-film (a-Si) PV module is a nections of modules, the effect of voltage drop due to technology highly expected as a module for low manufactur- shadow (shade) can be

Get Started

Thin Film Photovoltaic Modules with Structural Bonds

Apr 5, 2012 · voltaic module structures and related fabrication techniques. According to various embodiments, the structures include a structural bond related between two sealing sheets of

Get Started

Thin-Film Solar Panels

Feb 27, 2021 · Each thin-film solar panel is made of 3 main parts: Photovoltaic Material: This is the main semiconducting material and it''s the one responsible for converting sunlight into

Get Started

Flexible CIGS, CdTe and a-Si:H based thin film solar cells: A

May 1, 2020 · Flexible thin film solar cells such as CIGS, CdTe, and a-Si:H have received worldwide attention. Until now, Si solar cells dominate the photovoltaic market. Its production

Get Started

What Are Thin-Film Solar Panels?

6 days ago · Thin-film solar cells, also known as flexible or stick-on solar panels, are thin and lightweight, unlike traditional solar panels. Their production

Get Started

Film Module

Thin-film modules can show a highly homogeneous surface appearance and very little variation from module to module. This allows the assembly of large, highly homogeneous panels on

Get Started

A review of thin film solar cell technologies and challenges

Apr 1, 2017 · CIGS and CdTe hold the greatest promise for the future of thin film. Longevity, reliability, consumer confidence and greater investments must be established before thin film

Get Started

Types of Solar Panels: Monocrystalline vs

Jan 30, 2024 · Thin-film solar panels are made by depositing a thin layer of photovoltaic material onto a substrate, making them lightweight and flexible.

Get Started

Physical Properties of EVA and PVB Encapsulant

Apr 8, 2024 · Amorphous silicon thin film photovoltaic device has superstrate structure, in which light impinges on a conducting glass comprising transparent conductive oxide and silicon

Get Started

(PDF) A review of thin film solar cell

Jul 14, 2023 · Here we incorporate ionic liquids into the perovskite film and thence into positive–intrinsic–negative photovoltaic devices, increasing the device

Get Started

Flexible design of building integrated thin‐film

May 1, 2022 · The high cost of building integrated photovoltaics is one of the main reasons preventing a more widespread application. We propose a panel-on

Get Started

ZSW: Thin-film solar cells and modules

In 2014, the total global production of photovoltaic modules with a-Si, CdTe and CIGS absorbers amounted to 3,144 MW, which comprised 8% of the total annual production of solar modules.

Get Started

Internal structure of solar PV modules: (a) crystalline silicon

Partial shading affects the performance and reliability of thin-film and crystalline-silicon (c-Si) photovoltaic (PV) modules. In this paper, the thin-film and c-Si modules are experimentally

Get Started

Key issues in the design of floating photovoltaic structures

Aug 1, 2022 · PV modules are generally based on silicon technology, cadmium telluride, cadmium sulphide, organic and polymer cells, hybrid photovoltaic cells, and thin-film technology [78].

Get Started

All About Thin-Film Photovoltaic Cells (TFPV)

Jan 3, 2022 · Thin-film photovoltaic (TFPV) cells are an upgraded version of the 1st Gen solar cells, incorporating multiple thin PV layers in the mix instead of

Get Started

Optimization of laser-patterning process and module design

May 1, 2020 · Transparent hydrogenated amorphous silicon thin-film solar modules are fabricated using oxide-metal-oxide (OMO) electrodes as the back electrode for building-integrated

Get Started

Thin Film vs. Crystalline Silicon PV Modules

4 days ago · CIGS thin-film solar modules efficiency are more than 15.6%, are suitable for BIPV (Building Integrated Photovoltaic). Now, other than solar

Get Started

Thin-Film Solar Cells: Definition, Types & Costs

Jul 22, 2024 · Thin-film solar cells are a type of solar panel or semiconductor devices that convert sunlight into electricity through the photovoltaic effect.

Get Started

Structure and Materials of PV Modules

Nov 29, 2017 · Structure and Materials of PV Modules A crystalline silicon module must withstand various influences in order to remain functional for 25 years or even longer.

Get Started

Solution-Processed Thin Film Transparent Photovoltaics:

Oct 23, 2024 · Recent advancement in solution-processed thin film transparent photovoltaics (TPVs) is summarized, including perovskites, organics, and colloidal quantum dots. Pros and

Get Started

Long-term testing study of tensile ETFE, PTFE and PVDF

Mar 15, 2025 · However, Membrane structure has encountered some problems in the development of photovoltaic integration, such as low energy conversion efficiency, and the

Get Started

Schematic diagram of thin-film solar power generation

Thin-film solar cells have been referred to as second-generation solar photovoltaics (PV) or next-generation solutions for the renewable energy industry. Sun, X. et al. Firmly standing three

Get Started

Fab & criteria for thin-film and crystalline

May 21, 2024 · a photovoltaic solar cell is a difficult feat of technology in execution. The challenge of balancing cell structure design, material optimization and module technology to achieve

Get Started

What are thin-film solar cells? description, and types

Sep 26, 2019 · Thin-film solar cells are the second generation of solar cells. These cells are built by depositing one or more thin layers or thin film (TF) of photovoltaic material on a substrate,

Get Started

Schematic diagram of thin-film solar power generation

In general, thin film solar cell devices comprise of 6 basic layers, including glass substrate, metal back contact (Mo), p-type absorber layer, n-type buffer layer, transparent conducting oxide...

Get Started

Lightweight and flexible Cu(In,Ga)Se2 solar minimodules:

Oct 30, 2022 · The highly efficient CIGS solar modules with photovoltaic efficiency values greater than 19% demonstrated on the aforementioned glass substrates have a monolithically

Get Started

Thin-film, flexible photovoltaic module

Thin-film, flexible photovoltaic module Abstract A new, large-area, thin-film, flexible photovoltaic structure is disclosed, as well as a general fabrication procedure, including a preferably roll-to

Get Started

6 FAQs about [Thin-film photovoltaic module structure]

What are thin-film solar panels?

Thin-film solar panels use a 2 nd generation technology varying from the crystalline silicon (c-Si) modules, which is the most popular technology. Thin-film solar cells (TFSC) are manufactured using a single or multiple layers of PV elements over a surface comprised of a variety of glass, plastic, or metal.

What is a thin film solar cell?

What differs Thin-Film solar cells from monocrystalline and polycrystalline is that Thin-Film can be made using different materials. There are 3 types of solar Thin-Film cells: This type of Thin-Film is made from amorphous silicon (a-Si), which is a non-crystalline silicon making them much easier to produce than mono or polycrystalline solar cells.

What are the different types of thin-film solar cells?

Therefore, thin-film solar cells are generally classified according to the photovoltaic material used. According to these criteria, the following types of thin-film photovoltaic cells are found. Color-sensitive solar cells (DSC) and other organic solar cells. Cadmium telluride is the most advanced thin-film technology.

What are thin-film photovoltaic (TFPV) cells?

Thin-film photovoltaic (TFPV) cells arean upgraded version of the 1st Gen solar cells, incorporating multiple thin PV layers in the mix instead of the single one in its predecessor. These layers are around 300 times more delicate compared to a standard silicon panel and are also known as a thin-film solar cell.

How are thin-film solar cells produced?

Thin-film solar cells are produced through the deposition of one or more thin layers (referred to as thin films or TFs) of photovoltaic material onto a substrate.

How do thin-film solar modules differ from silicon-based technology?

The manufacture of thin-film modules therefore differs fundamentally from the manufacture of silicon-based technology. Solar modules with already interconnected cells are processed instead of individual cells. The contact surfaces, absorber and additional intermediate layers are deposited on large glass panes in integrated processes.

Related Articles

-

Thin-film photovoltaic module composition

Thin-film photovoltaic module composition

-

Thin-film photovoltaic module color

Thin-film photovoltaic module color

-

Thin-film photovoltaic panel prices

Thin-film photovoltaic panel prices

-

Malaysia single glass photovoltaic module panels

Malaysia single glass photovoltaic module panels

-

Does the photovoltaic inverter module have a battery

Does the photovoltaic inverter module have a battery

-

Photovoltaic cell module factory in southern Spain

Photovoltaic cell module factory in southern Spain

-

Ethiopia photovoltaic cell module manufacturers

Ethiopia photovoltaic cell module manufacturers

-

Solar photovoltaic module parameters

Solar photovoltaic module parameters

-

Solar photovoltaic module industry extension

Solar photovoltaic module industry extension

-

Czech multicrystalline photovoltaic module prices

Czech multicrystalline photovoltaic module prices

Commercial & Industrial Solar Storage Market Growth

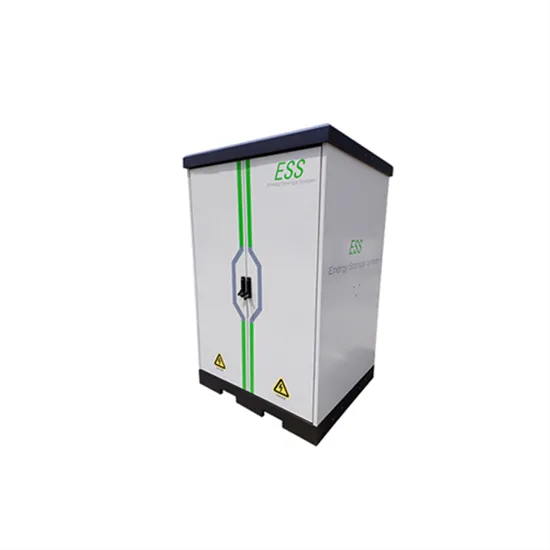

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.