Everything You Need To Know About Thin-Film

Thin-film solar panels are a type of photovoltaic solar panels that are made up of one or more thin layers of PV materials. These thin, light-absorbing layers can

Get Started

Thin-Film Silicon Photovoltaics

This contribution reviews some of the latest achievements and challenges in thin-film silicon photovoltaic (PV) technology based on amorphous and nanocrystalline silicon and their alloys.

Get Started

Mitsubishi Thin Film Photovoltaic Module

May 13, 2021 · Measured on an annual basis, the thin-film PV company. The Plant adopts a new installation method, with module generates 10% more power than the crystalline the power

Get Started

Mechanical properties of

May 21, 2024 · Power Generation AbStrAct Since the 1980s, ethylene-vinyl acetate (EVA) has been the standard encapsulation material for crystalline photovoltaic modules. From a

Get Started

What are thin-film solar cells? description, and types

Sep 26, 2019 · Thin-film solar cells are the second generation of solar cells. These cells are built by depositing one or more thin layers or thin film (TF) of photovoltaic material on a substrate,

Get Started

Thin Films

Dec 12, 2024 · Thinner absorber layers + non-inert absorber compounds = module performance more sensitive to encapsulation quality. Some unique failure modes for thin-film modules (e.g.,

Get Started

Inventions, innovations, and new technologies: Flexible and

Sep 1, 2023 · We review recent inventions and innovations to enhance the distinctive properties and functionalities of thin-film devices for successfully adapting in the emerging applications.

Get Started

What Are CIGS Thin-Film Solar Panels? When to

Mar 6, 2022 · Thin-film solar panels are among the most advanced and efficient power generation technologies created for the solar industry. These

Get Started

What are thin-film solar cells? description, and types

Sep 26, 2019 · Silicon modules are divided into three categories: Amorphous silicon photovoltaic cells Multicrystalline tandem photovoltaic cells Multicrystalline silicon thin film on glass The

Get Started

Thin Film vs. Crystalline Silicon PV Modules

4 days ago · CIGS thin-film solar modules efficiency are more than 15.6%, are suitable for BIPV (Building Integrated Photovoltaic). Now, other than solar

Get Started

CdTe photovoltaic technology: An overview of waste

Jun 1, 2024 · CdTe panel is a leader among thin-film technologies for solar panels and, according to some studies, promises the lowest production cost compared with other PV technology

Get Started

A comprehensive review of flexible cadmium telluride solar

Nov 1, 2023 · The thin film technology is more profitable and offers better performance compared to the first generation. However, reducing the overall package weight of a complete module

Get Started

Thin-Film Solar Cells: Definition, Types & Costs

Jul 22, 2024 · Thin-film solar cells are a type of solar panel or semiconductor devices that convert sunlight into electricity through the photovoltaic effect.

Get Started

ZSW: Thin-film solar cells and modules

The manufacture of thin-film modules therefore differs fundamentally from the manufacture of silicon-based technology. Solar modules with already

Get Started

Understanding the Composition of Solar Panels

Apr 7, 2023 · Thin film solar cells, also known as photovoltaic (PV) cells, are an alternative to traditional crystalline silicon-based solar cells. These cells are

Get Started

Thin-film Solar Overview | Cost, types, application, efficiency

Aug 25, 2019 · Rigid thin-film cells have other commercial applications (inserting or interleaving between two panes of glass) in some of the largest photovoltaic power stations in the world.

Get Started

Recent Advances on the Deposition of Thin Film

Jan 31, 2025 · The various thin film deposition techniques or methods such as vacuum-based magnetron sputtering, vacuum thermal evaporation, various

Get Started

Performance analysis of mono crystalline, poly crystalline and thin

Dec 1, 2021 · A protective glass covering is commonly applied to this type of thin-film technology. Thin-film solar panels can also be made using amorphous silicon (a-Si), which is similar to the

Get Started

Advanced Thin-Film Solar Panel Manufacturing:

Apr 3, 2025 · Thin-film solar panels represent a revolutionary advancement in solar PV technology, offering unprecedented flexibility and cost-effectiveness

Get Started

(PDF) Thin-Film Solar Cells: An Overview

Mar 1, 2004 · Schematic cross-sectional diagram of a thin-film photovoltaic module (adopted from Reference 10) Figures - uploaded by Puthur Paulson

Get Started

In-depth understanding of the composition of photovoltaic modules

Photovoltaic modules are mainly composed of the following parts: Battery Cells Battery cells are the core components of photovoltaic modules, and their function is to directly convert solar

Get Started

What is Thin Film Photovoltaic Module?

Nov 17, 2023 · Thin film photovoltaic modules or panels consist of layers of semiconductor materials like amorphous silicon, cadmium telluride, or copper indium gallium selenide. These

Get Started

Thin Film Photovoltaics

Thin film photovoltaic modules produce power at low cost per watt. They are ideal for large scale solar farms, as well as Building Integrated Photovoltaic applications (BIPV). They benefit from

Get Started

What Are Thin-Film Solar Panels?

6 days ago · Thin-film solar cells, also known as flexible or stick-on solar panels, are thin and lightweight, unlike traditional solar panels. Their production

Get Started

Editorial: Emerging thin-film solar cell research

Jun 16, 2025 · Collectively, these articles strengthen our understanding of thin-film photovoltaic materials and devices, from material synthesis to device architecture. They highlight critical

Get Started

Copper Indium Gallium Diselenide Solar Cells | Photovoltaic

Apr 3, 2025 · CIGS-based thin-film solar modules represent a high-efficiency alternative for large-scale, commercial solar modules. CIGS is a versatile material that can be fabricated by

Get Started

Thin-Film Solar Photovoltaics: Trends and Future Directions

Aug 7, 2025 · Thin-film photovoltaic (PV) technologies address crucial challenges in solar energy applications, including scalability, cost-effectiveness, and environmental sustainability.

Get Started

Solution-Processed Thin Film Transparent Photovoltaics:

Oct 23, 2024 · Recent advancement in solution-processed thin film transparent photovoltaics (TPVs) is summarized, including perovskites, organics, and colloidal quantum dots. Pros and

Get Started

6 FAQs about [Thin-film photovoltaic module composition]

What is a thin-film solar panel?

Thin-film modules use one of the following four technologies: cadmium telluride (CdTe), amorphous silicon (a-Si), copper indium gallium selenide (CIGS), and organic photovoltaic cells (OPV). They use less material than traditional panels, including toxic materials & their construction makes them highly bendable and less susceptible to cracks.

What are thin film solar cells?

Types and description Thin-film solar cells are the second generation of solar cells. These cells are built by depositing one or more thin layers or thin film (TF) of photovoltaic material on a substrate, such as glass, plastic, or metal. The thickness of the film varies from a few nanometers (nm) to tens of micrometers (µm).

What material is used for thin-film solar panels?

Cadmium telluride (CdTe) is the most popular material for manufacturers of thin-film solar panels. Using the EnergySage Marketplace, you can choose from various solar panel installers who can work with different types of thin-film and regular panels. What are thin-film solar panels?

What is a thin-film PV device?

Thin-film PV devices are module-based approaches to cell design. A thin-film module is a module-level PV device with its entire substrate coated in thin layers of semiconductor material using chemical vapor deposition techniques and then laser-scribed to delineate individual cells and make electrical connections between cells.

What are the advantages of thin-film solar cells?

Below is more information on each of the seven main advantages of thin-film solar cells. Light Weight: Thin-film solar cells are exceptionally lightweight due to their thin layers of photovoltaic material.

What is the difference between thin-film solar panels and monocrystalline solar panels?

The main difference between thin-film solar panels and other types, such as monocrystalline and polycrystalline, lies in their material composition and structure. Thin-film panels are made with layers of photovoltaic material that are only a few microns thick, resulting in a lightweight, flexible panel.

Related Articles

-

Thin-film photovoltaic module color

Thin-film photovoltaic module color

-

Thin-film photovoltaic module structure

Thin-film photovoltaic module structure

-

Kingston Double Glass Photovoltaic Module Company

Kingston Double Glass Photovoltaic Module Company

-

Solar photovoltaic module 1200wp

Solar photovoltaic module 1200wp

-

South Ossetia photovoltaic module sales price

South Ossetia photovoltaic module sales price

-

Solar Photovoltaic Module Services

Solar Photovoltaic Module Services

-

Photovoltaic module manufacturing project

Photovoltaic module manufacturing project

-

Uzbekistan thin film photovoltaic module glass

Uzbekistan thin film photovoltaic module glass

-

Price of photovoltaic module C level

Price of photovoltaic module C level

-

Photovoltaic cell module rework

Photovoltaic cell module rework

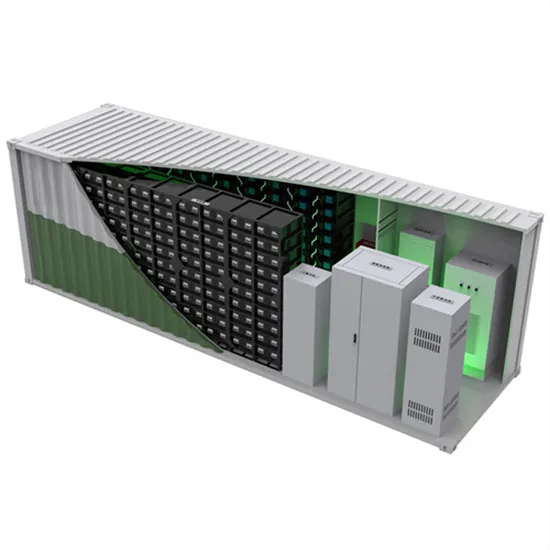

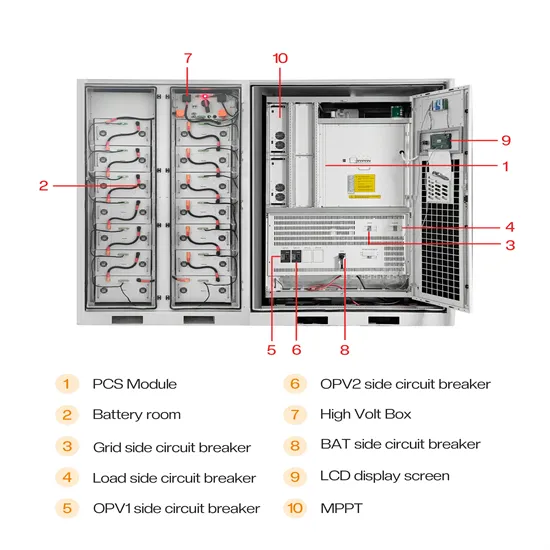

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.