Tandem amorphous/microcrystalline silicon thin-film solar modules

Aug 1, 2018 · Tandem amorphous/microcrystalline silicon thin-film solar modules with large-area panels, high energy yield, low light-induced degradation, and high damp-heat reliability.

Get Started

Everything You Need To Know About Thin-Film

Thin-film solar panels are made of very thin layers of photovoltaic materials, making them extremely lightweight and sometimes even flexible. You''ll find

Get Started

Monocrystalline, Polycrystalline, and Thin-Film

3 days ago · Thin-Film Solar Panels Thin-film panels are constructed from ultra-thin layers of photovoltaic materials, such as cadmium telluride or amorphous

Get Started

Colored PV Modules | part of Photovoltaic Solar Energy:

Jul 12, 2025 · It describes thin‐film interference, which is a typical optical process related to colors in surfaces on top of PV modules. There are several options for coloring the different layers in

Get Started

Types of Solar Panels: Monocrystalline vs

Jan 30, 2024 · Thin-film solar panels are made by depositing a thin layer of photovoltaic material onto a substrate, making them lightweight and flexible.

Get Started

Balancing aesthetics and efficiency of coloured opaque

Feb 20, 2025 · We provide an overview of various optical materials for PV colourization, focusing on easily mass-producible inorganic pigments, multilayer dielectric thin films and interference

Get Started

Multilayer thin film design for neutral-colored opaque

Jan 15, 2025 · For colorizing PV modules, it is expected that the multilayer thin film can enable a targeted color while minimizing its negative impact on PCE. One typical periodic film structure

Get Started

Thin Film Photovoltaics

This gives thin film photovoltaic modules greater design flexibility when integrated into the building envelope. Thin film photovoltaics consist of a stack of extremely thin photosensitive layers

Get Started

Study on glass colorization and reduction of multi-angle

May 1, 2025 · Solar photovoltaic modules have a single color that cannot meet the requirements of architectural aesthetics. In this paper, starting from the glass cover of thin-film solar cells, to

Get Started

The MorphoColor Concept for Colored

Jul 5, 2021 · PDF | We introduce a photonic color concept for integrated photovoltaic modules. Taking up the inspiration from the Morpho butterfly with

Get Started

Inventions, innovations, and new technologies: Flexible and

Sep 1, 2023 · We review recent inventions and innovations to enhance the distinctive properties and functionalities of thin-film devices for successfully adapting in the emerging applications.

Get Started

The research on a new type of BIPV modules constructed by thin-film

Download Citation | On Jun 1, 2014, Huacong Yu and others published The research on a new type of BIPV modules constructed by thin-film photovoltaic panel (or module)/PU/color organic

Get Started

Design of color tunable thin film polymer solar cells for photovoltaics

Apr 15, 2020 · Color tunable thin film polymer solar cells have demonstrated the potentials of a wide applications in photovoltaics printing, which is significant for ink pollution reduction and

Get Started

Flexible design of building integrated thin‐film

May 1, 2022 · The panel-on-demand concept for flexible design of building integrated thin-film photovoltaics requires new processes for glass cutting, a

Get Started

ASCA®-Technology: Organic photovoltaics for

Sustainable solution The ASCA ® -OPV film offers the shortest energy payback time (EPBT) in the photovoltaic market. The energy payback time (EPBT)

Get Started

Multilayer thin film design for neutral-colored opaque

Jan 1, 2025 · Furthermore, the MPCPV module possesses an efficiency of 9.6%, which is 4.1% higher than a single-color PV module (5.5%) but closer to conventional thin-film PV modules.

Get Started

Design of esthetic color for thin-film silicon semi-transparent

Dec 1, 2015 · Color design for large-area hydrogenated amorphous silicon (a-Si:H) semi-transparent glass-to-glass (GTG) photovoltaic (PV) modules has been studied for the

Get Started

Translucent, color-neutral and efficient

Mar 1, 2018 · Thin film perovskite photovoltaic devices combine high power conversion efficiencies with low weight, large area, high speed production

Get Started

Predicting the Electrical Behavior of Colored Photovoltaic Modules

Nov 24, 2024 · Therefore, the present work introduces a modeling framework to predict the short-circuit current (ISC) spectral response (SR) and the integrated ISC value of colored PV

Get Started

What are monocrystalline, polycrystalline and

Aug 25, 2014 · Basic introduction into solar panel and cell technology. Monocrystalline, polycrystalline and thin film solar panels and how to indentify

Get Started

Flexible design of building integrated thin‐film

May 1, 2022 · In this publication, we present the development status of three processes for (1) laser-based glass cutting, (2) front contacts with integrated

Get Started

Design of esthetic color for thin-film silicon semi-transparent

Oct 28, 2015 · Design of esthetic color for thin-film silicon semi-transparent photovoltaic modules - 道客巴巴

Get Started

The research on a new type of BIPV modules constructed by thin-film

Jun 13, 2014 · Building integrated photovoltaic is an important kind of power generation form, industrial electricity price is almost the same to commercial electricity in China. So developing

Get Started

See-through, light-through, and color modules for large

Jan 1, 2020 · See-through, light-through, and color modules are developed for large-area (1.3 m × 1.1 m) tandem amorphous/microcrystalline silicon thin-film solar modules for building

Get Started

Development of novel orange colored photovoltaic modules

Dec 1, 2024 · This work illustrates a novel approach for the development of orange multilayer interference coatings with improved angular stability of color while maximizing energy

Get Started

What are thin-film solar cells? description, and types

Sep 26, 2019 · Silicon modules are divided into three categories: Amorphous silicon photovoltaic cells Multicrystalline tandem photovoltaic cells Multicrystalline silicon thin film on glass The

Get Started

Photovoltaic thin-film modules

Disadvantages of thin-film PV modules As already mentioned, the efficiency of the amorphous solar modules is significantly lower than that of other photovoltaic

Get Started

Thin-Film Solar Panels: Technologies, Pros

Feb 7, 2024 · The photovoltaic (PV) industry is led by traditional rigid crystalline silicon (c-Si) technology, featuring high efficiency, low price and higher

Get Started

What Are CIGS Thin-Film Solar Panels? When to

Mar 6, 2022 · Thin-film solar panels are among the most advanced and efficient power generation technologies created for the solar industry. These

Get Started

CIGS Thin-Film Photovoltaics – The time to

2-in-1 Thin-film Photovoltaics Paired for Higher Performance ZSW combines perovskite with CIGS to build a tandem solar module with 21+ percent

Get Started

CIGS Thin-Film Solar Panels: An In-Depth Guide

Sep 15, 2024 · Thin-film solar cell technology is the second generation of photovoltaic (PV) solar cells, featuring a thin semiconductor going from a few

Get Started

Thin Film Photovoltaics

Jan 1, 2018 · Thin film technology has the answers and potential to eliminate many existing bottlenecks of c-Si photovoltaic (PV) programs experienced at different levels from module

Get Started

Design of esthetic color for thin-film silicon semi-transparent

Dec 1, 2015 · Development of tandem amorphous/microcrystalline silicon thin-film large see-through color solar panels with reflective layer and 4-step laser scribing for building-integrated

Get Started

6 FAQs about [Thin-film photovoltaic module color]

Can thin film solar modules be customized?

Up to now the serial interconnection using laser scribes after single deposition steps remains the standard for thin film solar modules. A panel-on-demand procedure for refinement of semi-fabricates to customized modules was proposed to allow for flexible design of building integrated thin-film photovoltaics.

How are thin-film solar modules made?

In the first step, thin-film solar modules (e.g., CIGS) are produced as semi-finished products or semi-fabricates in large quantities on large glass plates. These are then shipped to refinement centres positioned in the consumer markets.

How efficient are coloured opaque PV modules?

Our analysis covers the key features and theoretical efficiency limits of coloured opaque PV modules, noting that efficiencies of around 22% are practically achievable across most colours.

What is thin-film silicon (Si) PV technology?

Thin-film silicon (Si) PV technology is one of promising options for semi-transparent BIPVs because of abundant raw materials, industrial-proven mass production, flexible size, easy transmittance engineering and low temperature coefficient , .

What is Panel-on-demand design for integrated thin-film photovoltaics?

We propose a panel-on-demand concept for flexible design of building integrated thin-film photovoltaics to address this issue. The concept is based on the use of semi-finished PV modules (standard mass products) with subsequent refinement into BIPV PV modules. In this study, we demonstrate the three processes necessary to realize this concept.

Which solar cells are used in coloured opaque solar panels?

Most reported coloured opaque PV modules use c-Si solar cells 20, 36, 37, 40, 56, 86, with a few utilizing emerging solar cells such as perovskites 27, 87, likely due to the dominance of c-Si in the PV market and its high mass production efficiency 27.

Related Articles

-

Thin-film photovoltaic module composition

Thin-film photovoltaic module composition

-

Thin-film photovoltaic module structure

Thin-film photovoltaic module structure

-

Thin-film photovoltaic panel prices

Thin-film photovoltaic panel prices

-

Energy Storage Container Solar Photovoltaic Module Factory

Energy Storage Container Solar Photovoltaic Module Factory

-

Solar photovoltaic module industry extension

Solar photovoltaic module industry extension

-

210Double-glass photovoltaic module size

210Double-glass photovoltaic module size

-

El Salvador Solar Photovoltaic Module Factory

El Salvador Solar Photovoltaic Module Factory

-

Libreville Photovoltaic Cell Module

Libreville Photovoltaic Cell Module

-

Glass photovoltaic module sales in Kathmandu

Glass photovoltaic module sales in Kathmandu

-

Photovoltaic module panels produced in Nouakchott

Photovoltaic module panels produced in Nouakchott

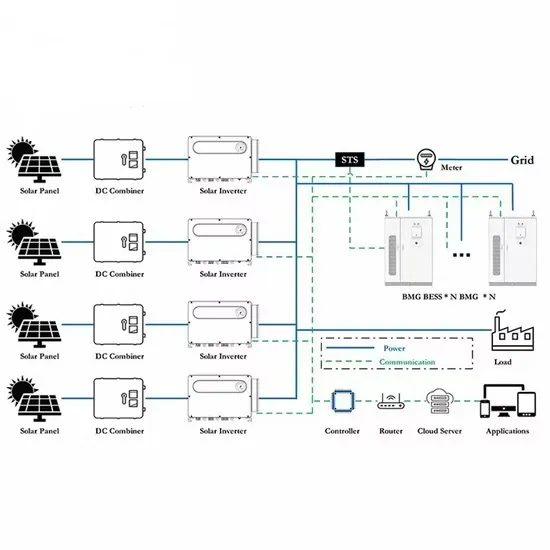

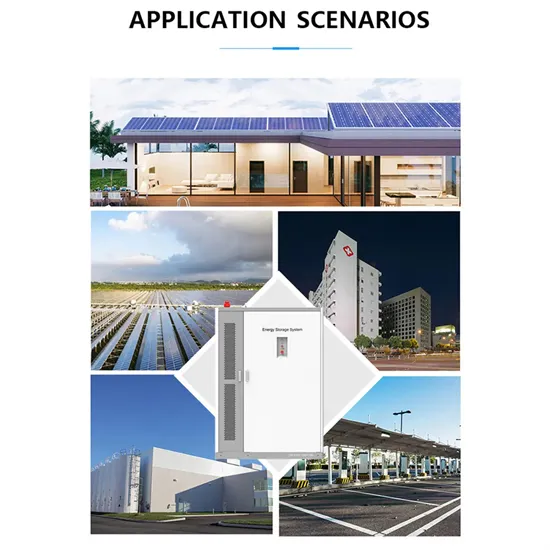

Commercial & Industrial Solar Storage Market Growth

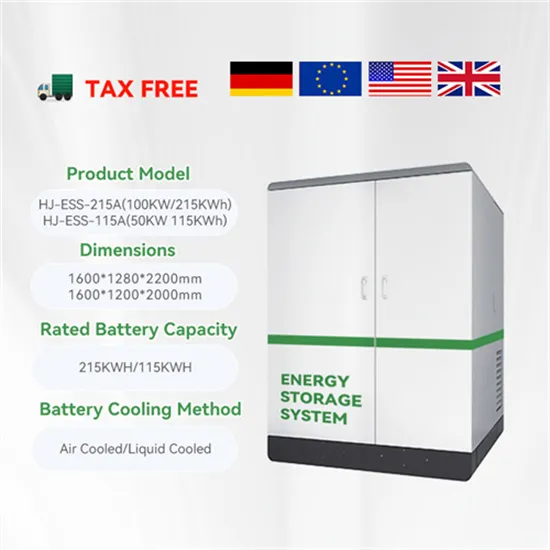

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

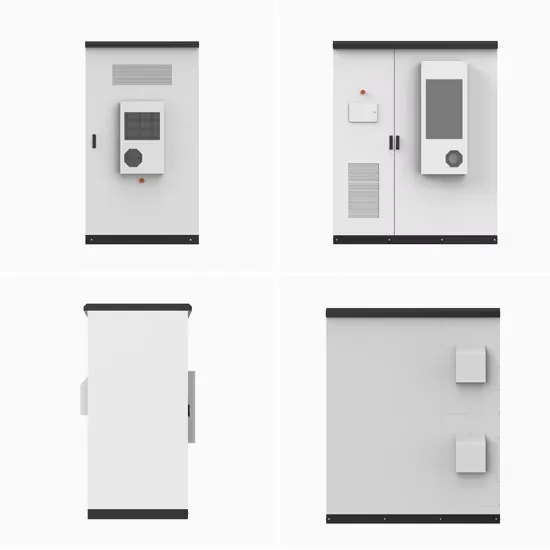

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.