What are the standard requirements for battery energy storage cabinets

Jun 2, 2024 · Battery energy storage cabinets must comply with several critical criteria: 1. Material durability, ensuring resilience against environmental factors, 2. Adequate thermal

Get Started

The Ultimate Guide to Battery Charging

Feb 14, 2025 · A lithium battery cabinet is designed to protect batteries from overheating, prevent thermal runaway, and contain any potential fires. These

Get Started

Standards specific to the battery manufacturing industry

Battery production requires high-precision machinery to ensure the quality and safety of finished products. 1. European battery regulations. The European Battery Regulation is a recent

Get Started

Lithium Battery Regulations and Standards in the

Jun 18, 2024 · Guide to UL standards, CPSIA, Amazon requirements, lab testing, and certification for lithium battery products to the US.

Get Started

Choosing the Right Battery Storage Cabinet: A

Jun 5, 2025 · This comprehensive guide provides a detailed overview of safety, design, compliance, and operational considerations for selecting and using

Get Started

Prevent fire damage caused by lithium-ion

Prevent fire damage caused by lithium-ion batteries?Lithium-ion batteries are convenient and powerful, but they also pose serious risks. A battery fire burns

Get Started

Safe Lithium-Battery Cabinets for Secure Storage

Apr 6, 2025 · Every link, from raw material procurement to production and processing and finished product inspection, is strictly controlled to ensure that each lithium - battery cabinet meets high

Get Started

Battery Energy Storage Systems: Main Considerations for

5 days ago · This webpage includes information from first responder and industry guidance as well as background information on battery energy storage systems (challenges & fires), BESS

Get Started

Choosing the Right Battery Storage Cabinet: A

Jun 5, 2025 · The right lithium-ion battery storage cabinet not only protects your assets but also enhances workplace safety and regulatory compliance. Given

Get Started

Comprehensive Lithium Storage Solutions:

Nov 8, 2024 · Explore comprehensive lithium storage solutions, covering safety guidelines, fire prevention, and compliance with the latest 2024 IFC standards.

Get Started

Lithium-ion Battery Safety

Jan 13, 2025 · Lithium-ion Batteries A lithium-ion battery contains one or more lithium cells that are electrically connected. Like all batteries, lithium battery cells contain a positive electrode, a

Get Started

Battery Cabinets and Enclosures Manufacture

Aug 5, 2025 · We''re one of the industry leader in manufacturing of energy storage systems that rank highest in quality, safety, maintenance and ease of use.

Get Started

Comprehensive Guide to Lithium Battery Cabinet Safety and

A high-quality lithium battery cabinet plays a crucial role in ensuring fire safety, minimizing chemical hazards, and meeting workplace regulations. This blog provides a complete overview

Get Started

Battery capacity cabinet measurement verification

Regulation 2023/1542 will come into effect on 18 August 2024. These include performance and durability requirements for industrial batteries, electric vehicle (EV) batteries, and light means

Get Started

How AZE Systems Manufactures BESS Battery Energy Storage Cabinets

Feb 21, 2025 · As the world transitions to renewable energy and smarter power grids, the demand for efficient and reliable energy storage solutions has never been greater. AZE Systems, a

Get Started

What is Lithium Battery Cleanroom?

May 8, 2025 · The battery production industry has a series of regulations and standards that have clear requirements for the cleanliness and safety of the production environment.

Get Started

Lithium Ion Battery Safety Guidance

Oct 16, 2019 · It is a good practice to use a lithium-ion battery fireproof safety bag or other fireproof container when storing batteries. Always follow manufacturer recommendations on

Get Started

Battery Cabinet Requirements

These fireproof lithium battery storage cabinets also feature self-closing doors and high-quality oil-damped door closers, further enhancing safety measures. Explore our range of lithium-ion

Get Started

Safe Storage of Lithium-Ion Battery: Energy Storage Cabinet

Apr 25, 2025 · An Energy Storage Cabinet, also known as a Lithium Battery Cabinet, is a specialized storage solution designed to safely house and protect lithium-ion batteries. These

Get Started

Battery Manufacturing Regulations and Standards Ensuring Quality and Safety

Apr 11, 2024 · APAC battery manufacturing sector stakeholders can ensure product quality, safety, and environmental sustainability by navigating this multifaceted regulatory landscape

Get Started

Charging and storage area | CEMO

A small cabinet size is therefore also completely in the spirit of what the fire brigade would prefer. That said, there is no need to forego flexible storage in

Get Started

Your Guide to Battery Energy Storage Regulatory Compliance

4 days ago · As the battery energy storage market evolves, understanding the regulatory landscape is critical for manufacturers and stakeholders. This guide offers insights into

Get Started

Battery Room Ventilation and Safety

Mar 15, 2023 · This safety factor is to allow for hydrogen production variations with changes in temperature, charge controller failure, and reduction in net volume of battery room due to

Get Started

Codes and Standards Governing Battery Safety

Aug 19, 2025 · Discover the key codes and standards governing battery safety and compliance in building and fire regulations. Learn about the various

Get Started

Quality Management for Battery Production: A Quality Gate

Jan 1, 2016 · High costs and large quality fluctuations during the production of high-energy batteries are considered to be among the main impediments of electric cars to succeed on the

Get Started

The Safety Cabinet Warehouse

The Best Battery Cabinets and most affordable battery cabinets in Singapore. Our Li-Ion Battery Charging & Storage Cabinets are designed as a preventative to

Get Started

Battery Testing for EVs: Ensuring Quality & Safety

Discover how battery testing for EVs—from lithium-ion cells to final battery packs—ensures high safety, quality, and reliability standards in electric vehicle manufacturing.

Get Started

Battery Manufacturing Process: Materials,

Jul 3, 2024 · The battery manufacturing process is a complex sequence of steps transforming raw materials into functional, reliable energy storage units. This

Get Started

The Ultimate Guide to Lithium-Ion Battery

Mar 21, 2025 · Discover the importance of lithium-ion battery storage cabinets for safe battery storage and charging. Learn best practices, key features, and

Get Started

Specifications and requirements for battery cabinets in

able; contact your local product supplier for the latest status. Features Battery rooms or stationary storage battery systems (SSBS) have code requirements such as fire-rated enclosure,

Get Started

New UL Standard Published: UL 1487, Battery Containment

2 days ago · Learn about the first edition of UL 1487, the Standard for Battery Containment Enclosures, a binational standard for the United States and Canada published by UL

Get Started

6 FAQs about [Battery cabinet production quality and safety requirements]

What are the CSA Standards for batteries & energy storage systems?

CSA provides testing and certification services for batteries and energy storage systems. Key CSA standards include : Standard for energy storage systems, covering electrical safety requirements. Standard for information technology equipment, including battery systems. Standard for rechargeable batteries used in portable appliances.

What are Canadian battery manufacturing regulations?

Canadian battery manufacturing regulations The battery manufacturing industry is subject to a strict set of standards and regulations designed to guarantee the safety, performance and durability of batteries. These standards cover various aspects, from production and recycling to traceability and environmental impact.

What are battery manufacturing standards?

They impose strict limits on the levels of cadmium, lead, nickel and other heavy metals in battery plant effluent. U.S. battery manufacturing standards are designed to ensure product safety, protect workers and minimize environmental impact. UL standards, CPSC guidelines, OSHA and EPA regulations all play a crucial role in shaping the industry.

Do battery manufacturing plants comply with OSHA standards?

Battery manufacturing plants must comply with specific OSHA standards to ensure worker safety. These standards cover various aspects of production, including: Management of hazardous substances used in battery manufacturing, including safe handling protocols and personal protective equipment (PPE).

What is a battery safety standard?

Standard for batteries used in light electric vehicles, such as electric scooters. It includes rigorous testing to ensure safety in the event of thermal runaway, overcharging and excessive discharge. Safety standard for battery-powered appliances, covering general requirements for ensuring the safety of battery systems in various appliances.

What are UL standards for battery manufacturing?

The battery manufacturing industry in the United States is governed by a set of standards and regulations designed to guarantee the safety, performance and durability of batteries. UL Standards are among the most widely recognized battery safety standards in the USA. They cover various aspects of battery manufacture and use, including :

Related Articles

-

About energy storage battery safety production

About energy storage battery safety production

-

Battery cabinet maintenance safety regulations

Battery cabinet maintenance safety regulations

-

Energy storage cabinet battery production line

Energy storage cabinet battery production line

-

San Marino outdoor communication battery cabinet photovoltaic production

San Marino outdoor communication battery cabinet photovoltaic production

-

Avalu outdoor communication battery cabinet production equipment

Avalu outdoor communication battery cabinet production equipment

-

Battery cabinet BMS production line

Battery cabinet BMS production line

-

Battery cabinet production line technical solution

Battery cabinet production line technical solution

-

Battery cabinet end plate production line base station

Battery cabinet end plate production line base station

-

Lead-acid battery cabinet safety solution

Lead-acid battery cabinet safety solution

-

New Energy Battery Cabinet Safety Test

New Energy Battery Cabinet Safety Test

Commercial & Industrial Solar Storage Market Growth

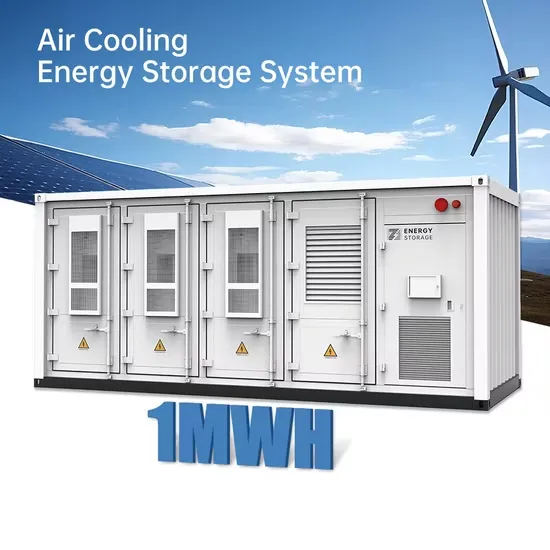

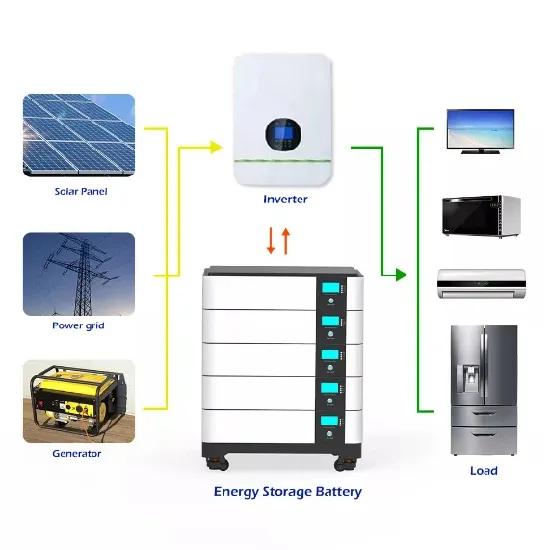

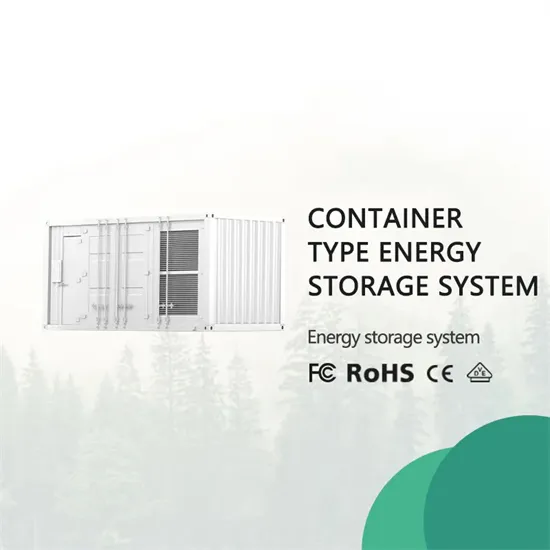

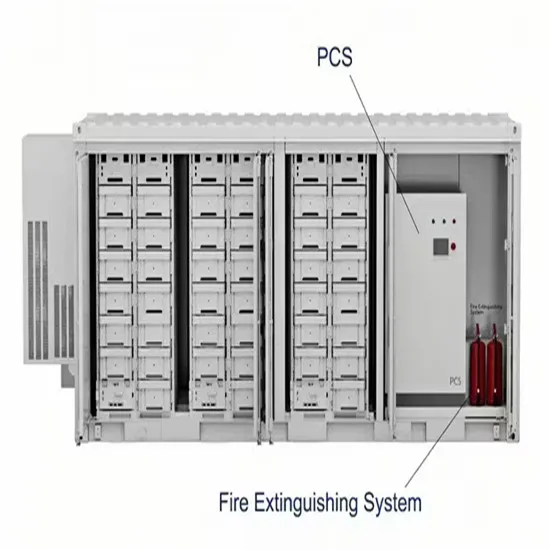

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.