Unlocking the Power: Distinguishing Battery

Dec 17, 2024 · Battery modules are ideal for applications that require higher power or larger capacity, such as electric vehicles, large portable power

Get Started

What is Battery Cell, Battery Module, and Battery

Jul 15, 2024 · Discover the differences between battery cell, battery module, and battery pack. Explore more on our blog about battery module.

Get Started

Design approaches for Li-ion battery packs: A review

Dec 20, 2023 · The paper aims to investigate what has been achieved in the last twenty years to understand current and future trends when designing battery packs. The goal is to analyze the

Get Started

Battery Cell VS Battery Module VS Battery Pack

Battery Module: A group of interconnected battery cells that increases voltage and capacity compared to individual cells. It includes wiring and connectors

Get Started

Sturcture of Battery: From Cell to Module and

Apr 21, 2025 · To review its structure more specifically, a battery cell can be further disassembled into the following components: Anode (Negative

Get Started

Battery Cell vs Battery Module vs Battery Pack

Mar 15, 2023 · Battery Module: Explanation and Function Unveil the significance of battery modules with these key insights: Bridge Between Cells and Packs:

Get Started

BATTERY MODULE AND PACK ASSEMBLY PROCESS

The battery production department focuses on battery production technology. Member companies supply machines, plants, machine components, tools and services in the entire process chain

Get Started

Understanding Battery Modules: A Simple Guide

Nov 16, 2024 · Battery modules offer significant advantages such as increased efficiency, scalability, and safety. For instance, lithium iron phosphate

Get Started

Study of lithium-ion battery module external short circuit

May 1, 2024 · This study is the first to investigate the risk factors and protection design of battery modules with varying voltage levels in the context of external short circuit (ESC) faults. Three

Get Started

Battery Cells, Modules, and Packs: Key Differences Explained

Apr 18, 2025 · In modern energy storage systems, batteries are structured into three key components: cells, modules, and packs. Each level of this structure plays a crucial role in

Get Started

Battery Module vs. Battery Pack: What''s the Difference?

Dec 5, 2024 · A battery pack typically includes the modules, a Battery Management System (BMS), cooling systems, safety features, and external connections to integrate the pack with

Get Started

The Modular Lithium Battery System:

Aug 15, 2025 · The smart and modular Lithium battery system : PowerModule The PowerModule product is a lithium battery system designed to be modular.

Get Started

Battery Cell, Module, Pack, what`s the Difference?

Nov 20, 2024 · A battery cell is the most basic functional unit of a lithium-ion battery. Looking at its structure, each battery cell contains five key

Get Started

Battery Cell, Module, or Pack: What''s the difference?

Each component serves a unique role: battery cells are the individual units that store energy, modules are groups of cells connected together, and packs are assemblies of modules that

Get Started

Battery Cell Module Pack: Everything You Need to Know

Sep 27, 2024 · While the terms "battery cell," "battery module," and "battery pack" are often used interchangeably, the battery cell module pack refers to different stages of the battery''s

Get Started

Lithium Battery PACK Production Line Processes

The Lithium Battery PACK production line encompasses processes like cell selection, module assembly, integration, aging tests, and quality checks,

Get Started

Power Battery Basics: Cells, Modules & Packs Explained

Jan 4, 2024 · Today, we''ll explore the three most crucial elements: cells, battery modules, and battery packs. 1. Cells: The Building Blocks. Cells serve as the fundamental building blocks of

Get Started

ELP400 EV Battery Pack Module Charging and

ELP400 has built-in various test and maintenance modes, which are suitable for the discharge, charging, cycle charging and discharging tests of various

Get Started

Battery Cell VS Battery Module VS Battery Pack

Mar 5, 2024 · Knowing the nuances of battery technology is essential for effective content optimization. This article will delve into the basics of the differences

Get Started

What Is A Lithium-Ion Battery Cell, Module, and Pack

Jan 30, 2024 · A lithium-ion battery module is a group of interconnected battery cells that work together to provide a higher level of voltage and capacity. Modules are designed to facilitate

Get Started

Intelligent Protected Lithium Battery Module

Aug 15, 2025 · This module is electrically compatible with most CubeSats and small satellites; a compatible EPS is required to charge the batteries. The

Get Started

What is the Battery Module?

May 27, 2024 · These modules are the building blocks of larger battery systems, providing the necessary energy storage and management for various

Get Started

Lithium Battery Modules Design Principles Explained %%sep%% Lithium

Jul 24, 2025 · Lithium battery modules rely on strong design principles to deliver safety and high performance. Engineers now use parametric optimization, advanced materials, and artificial

Get Started

The Ultimate Guide For Lithium-Ion Battery

This in-depth guide explores lithium-ion battery packs from the inside out. Learn about the key components like cells, BMS, thermal management, and enclosure.

Get Started

Thermal fault detection of lithium-ion battery packs through

Apr 28, 2025 · Mina Naguib and colleagues propose an integrated physicsand machine-learning-based method for early thermal fault detection in battery packs. This approach enhances

Get Started

Characterization study on external short circuit for lithium

Oct 1, 2024 · Characterization study on external short circuit for lithium-ion battery safety management: From single cell to module - ScienceDirect

Get Started

Battery Cells, Modules, and Packs | Lithium-ion

Lithium-Ion Batteries (Li-ion): Li-ion cells are highly popular due to their high energy density, lightweight design, and long cycle life. They are used in a wide

Get Started

What Are Battery Cells, Battery Modules, And

Feb 23, 2024 · Battery cell technology is the cornerstone of battery systems. The process of assembling lithium battery cells into groups is called PACK, which

Get Started

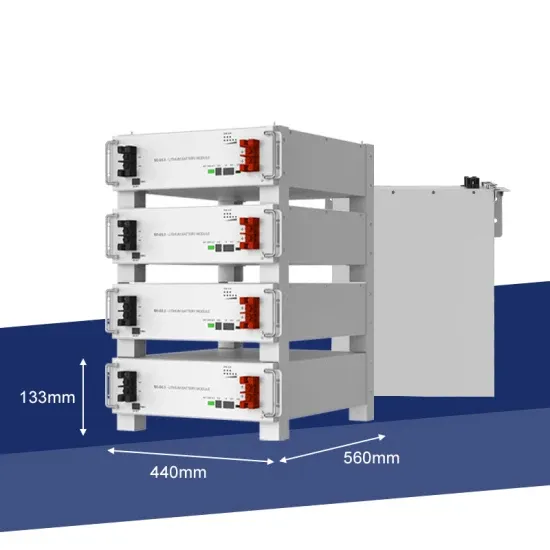

APC Smart-UPS Modular Ultra External Battery

APC Smart-UPS Modular Ultra External Battery Pack 4 Battery Modules Rackmount. Includes external battery pack frame and 4 x SRYLBM Genuine

Get Started

The Fundamentals of Battery/Module Pack Test

Oct 17, 2023 · The Importance of Battery Module and Pack Testing The battery market is growing rapidly due to the acceleration of electrification in the automotive, aerospace and energy

Get Started

IntelliPower

Jun 28, 2025 · IntelliPower - External Battery Modules (EBM) Request Demo Add to Quote Overview Specifications & Details Datasheets & Downloads Videos

Get Started

How to Distinguish Battery Cells, Battery Modules, and Battery

Components: A battery pack includes multiple battery modules, the necessary electrical connections, a BMS for overall pack management, and sometimes cooling systems.

Get Started

(PDF) BATTERY MODULE AND PACK ASSEMBLY

Feb 6, 2019 · Our second brochure on the subject "Assembly process of a battery module and battery pack" deals with both battery module assembly and

Get Started

Battery Cell, Module, Pack, what`s the Difference?

Nov 20, 2024 · As electric cars become increasingly common in our daily lives, terms like "battery cell," "module," and "pack" pop up frequently. But what exactly do these terms mean, and how

Get Started

6 FAQs about [Lithium battery pack external module]

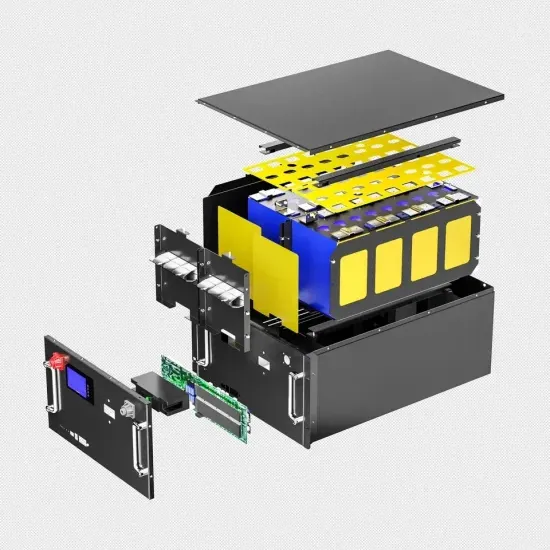

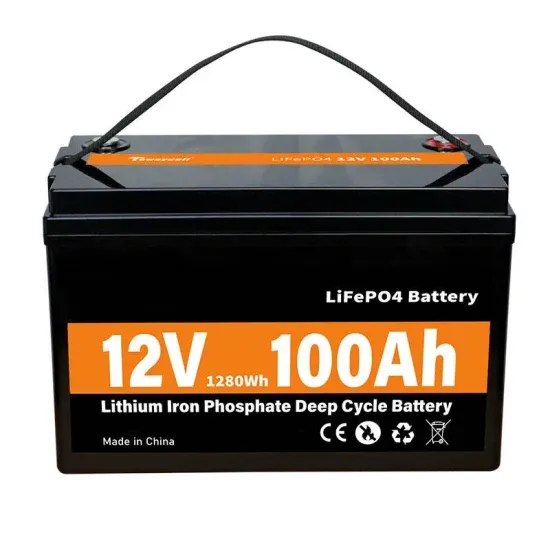

What is a lithium battery module pack?

Lithium batteries are an essential part of modern technology, powering everything from smartphones to electric vehicles. While the terms “battery cell,” “battery module,” and “battery pack” are often used interchangeably, the battery cell module pack refers to different stages of the battery’s construction.

What are battery cells & modules & packs?

Battery cells, modules, and packs are different stages in battery applications. In the battery pack, to safely and effectively manage hundreds of single battery cells, the cells are not randomly placed in the power battery shell but orderly according to modules and packages. The smallest unit is the battery cell. A group of cells can form a module.

What is a modular battery pack?

A modular battery pack takes the concept of modularity to the next level by incorporating interchangeable and stackable battery modules. Each module contains a set number of battery cells, and these modules can be added or removed as needed to adjust the pack's capacity or voltage.

What is a lithium-ion battery module?

A lithium-ion battery module is a group of interconnected battery cells that work together to provide a higher level of voltage and capacity. Modules are designed to facilitate efficient cooling and thermal management, ensuring that the temperature within the battery remains within safe operating limits.

What is the structure of a lithium battery?

The general structure of lithium batteries is a cell, battery module and battery pack. Battery cell technology is the cornerstone of battery systems. The process of assembling lithium battery cells into groups is called PACK, which can be a single battery or a battery module connected in series and parallel.

What is a battery module?

A battery module is a system composed of a certain number of cells in a designed series and parallel structure as needed. By connecting the cells in series, the voltages of multiple cells are accumulated, thereby achieving an output voltage based on a corresponding multiple of the cell voltage.

Related Articles

-

Price difference between lithium battery module and pack

Price difference between lithium battery module and pack

-

Tripoli lithium battery module pack

Tripoli lithium battery module pack

-

Rabat good lithium battery pack factory price

Rabat good lithium battery pack factory price

-

Is it useful to replenish power with a lithium battery pack alone

Is it useful to replenish power with a lithium battery pack alone

-

3 7V rechargeable lithium battery pack

3 7V rechargeable lithium battery pack

-

Cyprus 60ah lithium battery pack

Cyprus 60ah lithium battery pack

-

Judging the quality of lithium battery pack cells

Judging the quality of lithium battery pack cells

-

Creo design lithium battery pack

Creo design lithium battery pack

-

Estonia 24v lithium battery pack

Estonia 24v lithium battery pack

-

Self-discharge of lithium battery pack

Self-discharge of lithium battery pack

Commercial & Industrial Solar Storage Market Growth

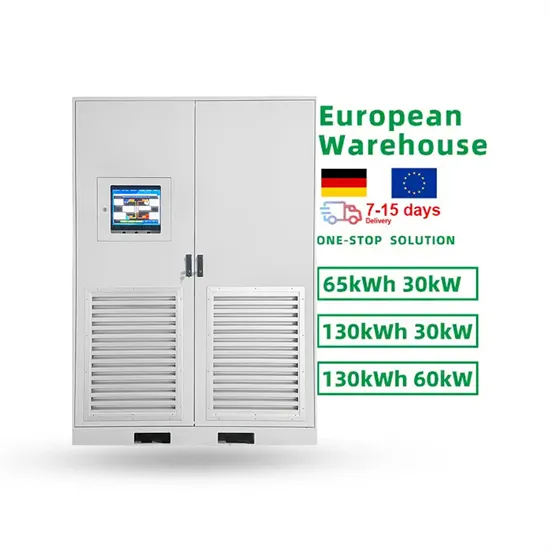

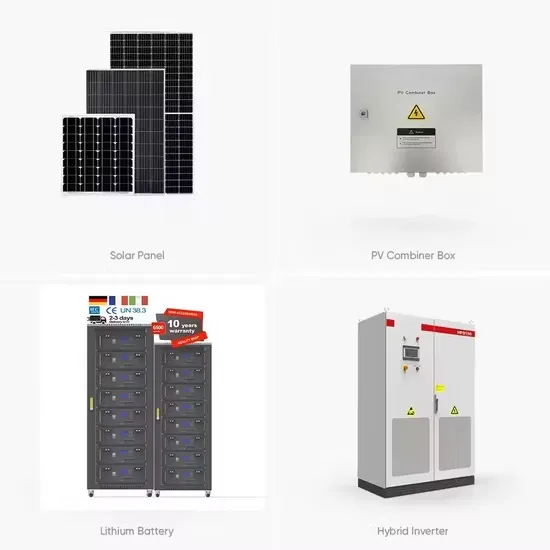

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.