Coupledâ inductor singleâ stage boost inverter for gridâ

Dec 22, 2020 · By introducing an impedance network including coupled inductor in front of the three-phase inverter bridge, and adjusting the previously forbidden shoot-through zero state,

Get Started

Inverter Analysis and Design

Feb 4, 2025 · Inverter Analysis and Design The inverter stage is a basic building block for digital logic circuits and memory cells. A generic inverter stage is illustrated below on the left. It

Get Started

Design and Application Considerations of Input Filter to

Mar 20, 2021 · The main purposes of an input filter are to suppress the noise and surge from the front-stage power supply and to decrease the interference signal at the switching frequency

Get Started

Modulation and control of transformerless boosting inverters

Apr 23, 2025 · This first configuration consists of a two-stage DC–DC–AC converter comprised of a DC–DC boost chopper and a three-phase voltage source inverter.

Get Started

Operation of Active Front-End Rectifier in Electric Drive

Sep 25, 2018 · 2. Control method A simplified scheme of the drive under investigation is shown in Fig. 1. The front-end controlled rectifier is connected to the mains through input filter inductors.

Get Started

The Inverter Stage: Unlocking the Power of

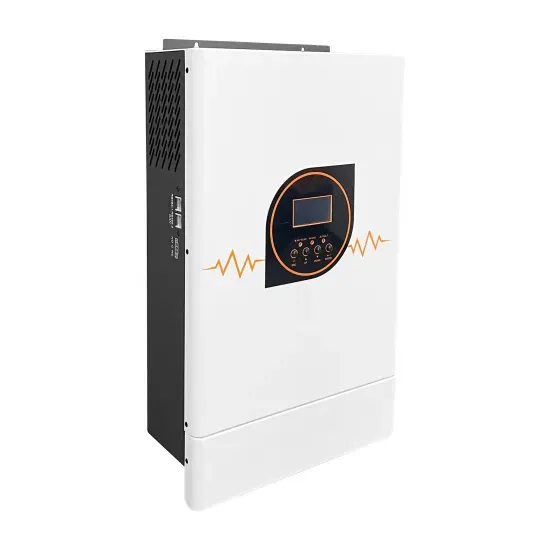

Jan 17, 2024 · The inverter stage is the "muscle" of the drive – a power electronics block that provides the regulated, conditioned power directly to the

Get Started

Control Method of Two-Stage Grid-Connected PV

Mar 30, 2024 · By controlling the DC link voltage at the front stage and the PWM of the inverter circuit at backstage, an LCL-type PV three-phase grid-tied inverter system is established. The

Get Started

Front-stage voltage-adjustment inverter

The front-stage voltage-adjustment unit determines a voltage-adjustment level to change the voltage of the input power according to the dimming signal and adjusts it according to the

Get Started

Crucial Start-Up Voltage for Solar Inverters

Sep 29, 2023 · Understanding the start-up voltage is crucial for optimizing the performance and efficiency of the inverter. The input voltage of a solar inverter

Get Started

Power Inverters Explained

Apr 25, 2020 · FREE COURSE!! Learn the basic working principle of power inverters, how they work, why we use them, where we use them and their

Get Started

Microsoft PowerPoint

Sep 16, 2009 · Layout the inverter using the Mentor tools, extract parasitics, and simulate the extracted circuit on HSPICE t o mak e sure th at your d esi gn conf orms t o th e specifi ifi cati on.

Get Started

9. Inverter Settings

What Causes Voltage Swing in Inverter Front Stages? Voltage swing refers to fluctuations in voltage levels at the input or early processing stages of an inverter. This phenomenon is

Get Started

Understanding Voltage Swing in Inverter Front Stages

Voltage swing in inverter front stages impacts performance and efficiency. Learn why it happens, how to mitigate it, and explore real-world case studies.

Get Started

How to Optimize Your Inverter Settings for Solar

6 days ago · Set the Correct Input Voltage Range. The inverter''s input voltage range determines the voltage at which the solar panel array will operate.

Get Started

The current status and development of DC/AC

Apr 14, 2023 · The advantages, applications, and development trends of DC/AC inverter technology are compared with conventional inverter technology. The

Get Started

Microsoft PowerPoint

Sep 16, 2009 · Design a static CMOS inverter with 0.4pF load capacitance. Make sure that you have equal rise and fall times. Layout the inverter using the Mentor tools, extract parasitics,

Get Started

Inverter Analysis and Design

Feb 4, 2025 · To determine the switching times we must first recognize that the reason an inverter output does not instantaneously change in response to an change of its input is because there

Get Started

A high efficiency PV micro-inverter with grid support functions

Sep 18, 2014 · This paper presents a new photovoltaic (PV) micro-inverter topology. The topology is based on a partial power processing resonant front end dc-dc stage, followed by an

Get Started

4 steps of correctly configuring the solar inverter

Jan 29, 2025 · By accurately setting parameters like the input voltage, output voltage, frequency, and power factor, the inverter can operate at its optimum

Get Started

10. Description of Settings

Sep 13, 2024 · 10.2.3. AC Voltage Connection and Disconnection Voltage limits at which feedback relay opens/closes. These are the limits at which the unit

Get Started

Voltage Source Inverter Design Guide (Rev. B)

Aug 25, 2017 · To control the inverter stage for desired operation voltage and current need to be sensed for processing by the digital controller. The design implements sensing scheme based

Get Started

Paper Title (use style: paper title)

The factors that influence the change of operating modes are: the load current, the input voltage, the output voltage. the most critical case is the one with higher mains voltage because the

Get Started

DC to AC Conversion (INVERTER)

May 23, 2013 · The Amplitude of the carrier wa veform Frequency of the modulating waveform M MODULATION RATIO M ( ) voltage and input (DC) voltage, respective ly. where, are

Get Started

Active Front End (AFE)

Jan 24, 2024 · This technical note introduces the working principle of an Active Front End (AFE) and presents an implementation example built with the TPI

Get Started

Basic principles of regenerative drive operation

Mar 22, 2016 · In this post we offer an introductory overview of regenerative drive operation (also referred to as "Active Front End" or "AFE"), covering the basic

Get Started

Switched inductor based transformerless boost inverter

Jan 1, 2022 · When the input voltage is low, the traditional voltage source inverter is usually added a DC-DC boost circuit at its front stage. So, the step-up inverter can be realized by

Get Started

Grid Connected Inverter Reference Design (Rev. D)

May 11, 2022 · Description This reference design implements single-phase inverter (DC/AC) control using a C2000TM microcontroller (MCU). The design supports two modes of operation

Get Started

Single stage boost inverter with low switching

ABSTRACT. In Conventional full bridge inverters, the output voltage is lower than that of the input DC voltage. Front end step up converters are generally required in applications where the

Get Started

CSM_Inverter_TG_E_1_1

Mar 27, 2016 · An inverter uses this feature to freely control the speed and torque of a motor. This type of control, in which the frequency and voltage are freely set, is called pulse width

Get Started

6 FAQs about [Change the inverter front-stage input voltage]

How do I set up a power stage for an inverter?

Enter 60 Hz for frequency for the AC waveform. This will be the frequency of the inverter output. Under Inverter Power Stage Parameters, Enter 110 Vrms for the output voltage. This will be the value that the AC output will regulate to. Type Ctrl-S to save the page. Right-click on the project name. Select Rebuild Project.

What are inverter settings?

Inverter Settings 1. To set output voltage of inverter - This is normally 230 Vac. Possible values 210V ~ 245V. 2. Used to enable/disable the internal ground relay functionality. Connection between N and PE during inverter operation. - The ground relay is useful when an earth-leakage circuit-breaker is part of the installation.

What is an inverter stage?

The inverter stage is a basic building block for digital logic circuits and memory cells. A generic inverter stage is illustrated below on the left. It consists of two devices,

How do I set up a closed voltage inverter?

On the powerSUITE page, select Closed Voltage and Curent Loop under Project Options. Select AC for output. Select SDFM for sensing if available on the design. Enter 60 Hz for frequency for the AC waveform. This will be the frequency of the inverter output. Under Inverter Power Stage Parameters, Enter 110 Vrms for the output voltage.

When does a DC inverter start?

The inverter starts as soon as the DC bus voltage is present at a greater level than 10% of the AC maximum. Observe the controlled AC voltage waveform on the output. The frequency and the amplitude of the AC voltage is determined by the values on the powerSUITE page of the solution.

How do I design a static CMOS inverter?

Design a static CMOS inverter with 0.4pF load capacitance. Make sure that you have equal rise and fall times. Layout the inverter using the Mentor tools, extract parasitics, and simulate the extracted circuit on HSPICE t o mak e sure th at your d esi gn conf orms t o th e specifi ifi cati on. Do the same analysis for a three input NAND gate.

Related Articles

-

Change the input voltage of photovoltaic inverter

Change the input voltage of photovoltaic inverter

-

What is the input voltage of the inverter

What is the input voltage of the inverter

-

The front-stage output voltage of the inverter

The front-stage output voltage of the inverter

-

Inverter DC voltage input range

Inverter DC voltage input range

-

Manila PV inverter input voltage

Manila PV inverter input voltage

-

Power inverter input voltage

Power inverter input voltage

-

What is the input voltage of the communication inverter

What is the input voltage of the communication inverter

-

Single-phase photovoltaic inverter input voltage

Single-phase photovoltaic inverter input voltage

-

Inverter group input voltage

Inverter group input voltage

-

Inverter input voltage is too high or too low

Inverter input voltage is too high or too low

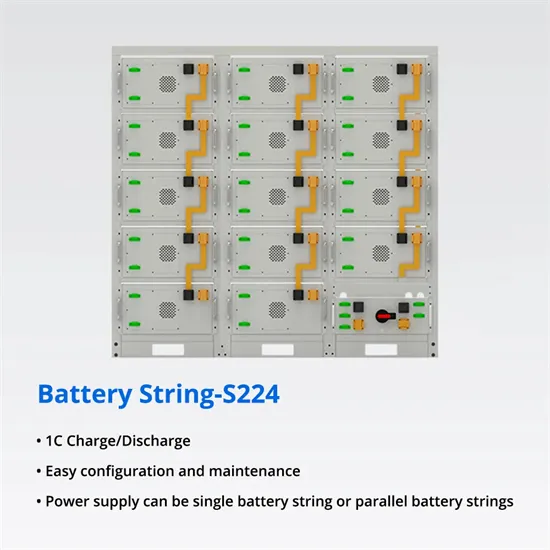

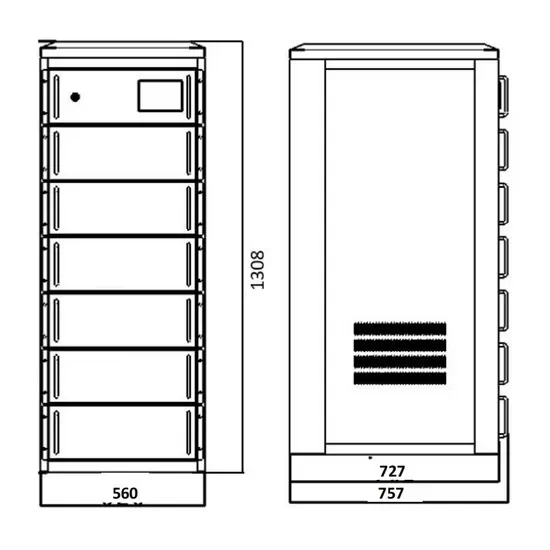

Commercial & Industrial Solar Storage Market Growth

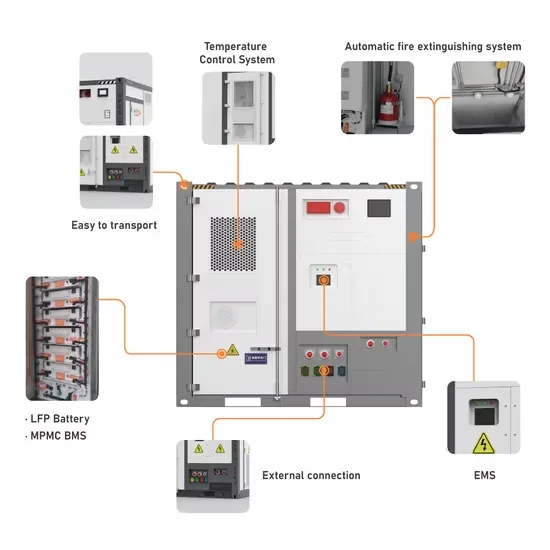

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.