Battery Module: Manufacturing, Assembly and Test Process

Dec 28, 2022 · In the Previous article, we saw the first three parts of the Battery Pack Manufacturing process: Electrode Manufacturing, Cell Assembly, Cell Finishing. Article Link. In

Get Started

Assembly line for battery modules and battery packs

6 days ago · For cell/module pack assembly, PIA Automation offers flexible and highly automated systems for the efficient production of battery cells, modules, and battery packs. These

Get Started

Electric vehicle battery production process

6 days ago · Our electric vehicle battery assembly, joining and inspection technologies drive productivity, quality, and performance of your electric

Get Started

How are Lithium-ion Battery Packs Manufactured?

Lithium-ion battery packs are manufactured through a meticulous process that includes two key parts: the Battery Management System (BMS) and the battery pack assembly. The BMS is

Get Started

China Battery Pack Assembly Line Manufacturers Suppliers

Aug 13, 2025 · ACEY is one of the most professional battery pack assembly line manufacturers and suppliers in China, specializing in providing high-quality products and services. Please

Get Started

PRODUCTION PROCESS OF BATTERY MODULES AND

Feb 7, 2024 · Segments of the production line The production line of a battery modules and packs has three main areas with major differences in terms of batch sizes, process speeds and

Get Started

Battery Module & Pack Manufacturing: Step-by

Apr 19, 2025 · As India and other emerging markets ramp up battery pack assembly, the global blueprint is clear: automation, flexibility, and integrated

Get Started

Lithium-Ion Battery Assembly Process & Key

May 17, 2025 · Discover the key stages in the lithium-ion battery assembly process, from raw materials to pack assembly. Learn how battery-making

Get Started

Battery Manufacturing Automation From Bosch

Our portfolio of innovative, flexible and complete production solutions enables battery manufacturers to get to market faster through cross-technology

Get Started

Lithium Battery PACK Production Line Processes

The Lithium Battery PACK production line encompasses processes like cell selection, module assembly, integration, aging tests, and quality checks,

Get Started

Battery Manufacturing and Assembly

2 days ago · Cells, modules, packs, cases and more We understand the inherent complexity of battery-based power options and can help contribute to the

Get Started

Innovating battery assembly

Aug 13, 2025 · We have outlined a complete battery assembly process for prismatic cells – from the single cell to the finished battery pack. We help our customers develop unique joining

Get Started

Lithium-Ion Battery Pack Manufacturing Process

Jun 4, 2025 · The process of lithium-ion battery pack manufacturing involves meticulous steps from cell sorting to final testing and assembly. Each phase

Get Started

GM Battery VP Gets an Up-Close Look at the

Jun 6, 2025 · Like all GM plants that produce EVs, Factory ZERO has a Rechargeable Energy Storage System (RESS) department that assembles

Get Started

Automated battery manufacturing

Just push the button Cutting-edge research and prototype factories are helping to advance the automation of EV component manufacturing, writes Nick Flaherty

Get Started

Understanding Lithium Ion Battery Manufacture

Jun 28, 2024 · The production of a lithium battery pack is a multifaceted process, involving several crucial steps to guarantee the final product''s quality and

Get Started

Battery Pack Assembly: From Cells to Power Packs

Discover how individual battery cells become high-performance battery packs. Learn about cell connection, modularization, and the critical role of battery

Get Started

Lithium-ion Battery Pack Manufacturing Process & Design

Jul 28, 2023 · In this article, we will explore the world of battery packs, including how engineers evaluate and design custom solutions, the step-by-step manufacturing process, critical quality

Get Started

EV Battery Pack Assembly

EV battery pack assembly is an essential part of battery production automation. Making up up to 60% of the cost of an electric vehicle (EV), the battery is the

Get Started

KNOWLEDGE PAPER ON LITHIUM-ION BATTERY

Jan 22, 2024 · Shapes of lithium-ion cell Types of Li-ion cells Nomenclature of lithium-ion cell/battery Battery-pack assembly line Cell testing machine Module testing machine Pack

Get Started

Battery Pack Assembly Machine | Battery Pack Manufacturers | Battery

Tmax is the most professional battery pack manufacturers,we offer high quality battery pack assembly machine and battery assembly machine for battery research and manufacturing.

Get Started

Battery Pack Manufacturing Process

Mar 15, 2025 · From raw material selection to final assembly, each step plays a vital role in quality and reliability. In this post, you''ll learn the entire battery pack manufacturing process. We''ll

Get Started

BATTERY MODULE AND PACK ASSEMBLY PROCESS

The battery production department focuses on battery production technology. Member companies supply machines, plants, machine components, tools and services in the entire process chain

Get Started

Lithium Battery Module Pack Assembly Line

In the rapidly evolving electric vehicle (EV) and energy storage markets, the Lithium Battery Module Pack Assembly Line plays a pivotal role in ensuring high-efficiency, safety, and

Get Started

Explained: Our battery plant design and

Aug 9, 2024 · Our battery plant and simulation trial will show you how a battery module and pack assembly line can be updated within a gigafactory using

Get Started

Design for Assembly and Disassembly of Battery Packs

Aug 23, 2019 · The design solutions are assessed from an assembly, disassembly and modularity point of view to establish what solutions are of interest. Based on the evaluation, an "ideal"

Get Started

Building Better Batteries | 2019-08-05 | ASSEMBLY

Aug 5, 2019 · "Adhesives and sealants also play an important role in all stages of battery manufacturing, including cell production, module production and

Get Started

Mastering the Battery Pack Assembly Process: A

Jan 23, 2025 · What is the Battery Pack Assembly Process? The battery pack assembly process is a meticulously planned sequence of steps that

Get Started

Automated assembly of Li-ion vehicle batteries: A feasibility study

Jan 1, 2020 · Electric Vehicles (EVs) with rechargeable Lithium-Ion batteries (Li-ion) are at the forefront of the global trend for lower-emission transportation and decarbonisation. Capable

Get Started

Optimize Battery Assembly Line with Design and

4 days ago · Discover the key features of a modern battery pack assembly line and how expert design and automation can boost performance, flexibility and

Get Started

China Battery Pack Assembly Line, Battery Pasting Machine

Aug 13, 2025 · Xiamen Acey New Energy Technology Co.,Ltd: Expert of electric vehicle battery making solution, lithium ion battery pack assembly line, battery module assembly consultation,

Get Started

Related Articles

-

How much does a lithium battery pack factory cost

How much does a lithium battery pack factory cost

-

Pack battery factory new energy vehicles

Pack battery factory new energy vehicles

-

Battery PACK factory in Saudi Arabia

Battery PACK factory in Saudi Arabia

-

Praia regular lithium battery pack factory price

Praia regular lithium battery pack factory price

-

48v lithium battery pack factory

48v lithium battery pack factory

-

Assembly of lithium titanate battery pack

Assembly of lithium titanate battery pack

-

Huawei Estonia cylindrical battery pack factory

Huawei Estonia cylindrical battery pack factory

-

Seychelles pack lithium battery factory

Seychelles pack lithium battery factory

-

Tunisia battery pack factory

Tunisia battery pack factory

-

Vietnam Pack Battery Factory

Vietnam Pack Battery Factory

Commercial & Industrial Solar Storage Market Growth

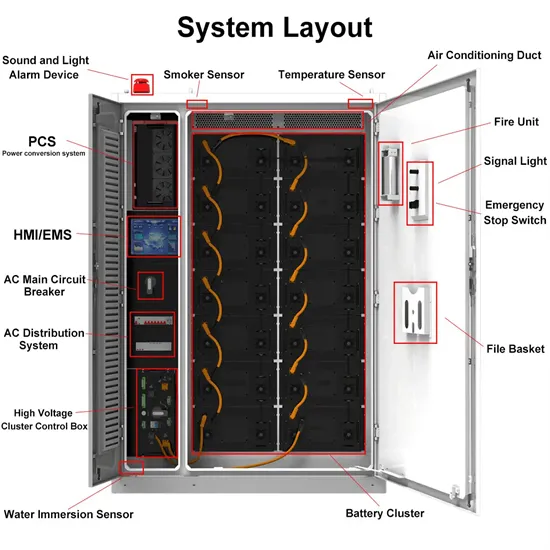

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.