Automated production of battery cabinets

Each battery pack passes through the systematically linked production processes, which are partly manual and partly automated: From kitting, the compilation of the components required

Get Started

The future of battery manufacturing: embracing advanced automation

To keep up with this demand, battery manufacturers are turning to advanced automation solutions. These technologies not only leverage best practices in automation to enhance

Get Started

New Energy Automation

1 day ago · The production line categories are complete, and there are delivery cases for household storage, commercial storage, energy storage battery

Get Started

Energy-saving feedback type battery aging cabinet

Nov 28, 2024 · Energy-saving feedback type battery aging cabinet Energy-saving feedback type battery aging cabinet is a kind of equipment that plays an important role in the production and

Get Started

Lithium Battery Production Equipment Supplier

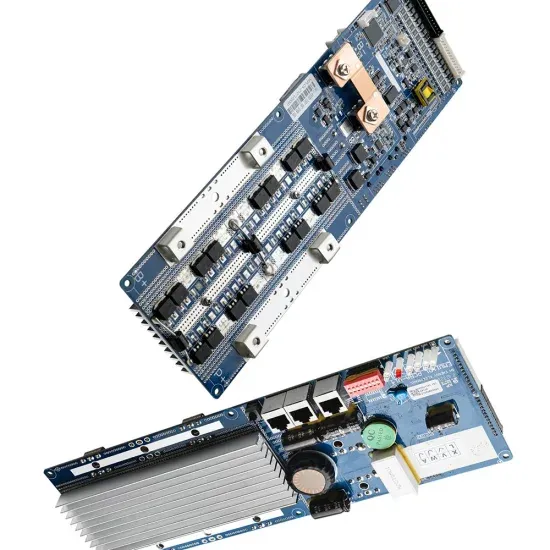

Single-Side Automatic Spot Weldi Precision spot welding for different battery types, ensuring high-quality and reliable connections tomatic operation for

Get Started

The Art and Science Behind Energy Storage Cabinet Production

Material selection: Cold-rolled steel (for durability) meets aerospace-grade aluminum (for lightweighting) Component prep: Laser cutting transforms sheets into cabinet "puzzle pieces"

Get Started

BATTERY PRODUCTION OF THE FUTURE

Jan 2, 2025 · We make your battery production more flexible, transparent and intelligent. All components, modules, and system solutions from Bosch Rexroth are based on open

Get Started

Automation solutions for battery production

Oct 30, 2024 · Automation solutions for battery production. High speed, high throughput, maximum reliability, repetition accuracy and low costs: these are the features that are required

Get Started

How Siemens automated maritime battery

Aug 30, 2020 · Siemens'' maritime battery production line in Norway has eight configurable robot cells and seven AGVs for handling inter-cell logistics.

Get Started

Fully Automated Battery Manufacturing

Fully Automated Battery Manufacturing Development of flexible, high-throughput battery manufacturing line using advanced conveyance/motion control, precision web handling, and

Get Started

HuiYao Intel

Our production line for prismatic battery modules stands out for its ability to meet the growing demands of the energy storage market. By prioritizing this sector, we aim to provide reliable

Get Started

Battery assembly solution

Aug 19, 2025 · At JOT Automation, we provide cutting-edge solutions for battery module assembly and battery pack assembly, ensuring seamless integration

Get Started

Transforming Battery Manufacturing:

Jan 7, 2025 · The global battery manufacturing industry is in the midst of an evolution driven by advanced automation, AI and the rapid rise in EV and

Get Started

New Energy Automation

1 day ago · FHS provides customers with innovative manufacturing and assembly solutions for square, soft, and cylindrical battery cells. We will tailor an

Get Started

Automation in battery production

Dec 18, 2023 · From the individual battery cell to the assembly of complete battery packs: With many years of expertise, KUKA covers the entire value chain in battery production systems

Get Started

Battery Manufacturing Basics from CATL''s Cell

Jun 13, 2021 · A summary of CATL''s battery production process collected from publicly available sources is presented. The 3 main production stages and 14

Get Started

Automation in battery production

Automation in battery production From the individual battery cell to the assembly of complete battery packs: With many years of expertise, KUKA covers the

Get Started

Home | Bosch Manufacturing Solutions | BMG

5 days ago · Our experts will showcase how smart automation, data-driven insights, and AI-supported systems can help you optimize operations, reduce

Get Started

Lithium Battery Formation and Capacity Grading Cabinet

Oct 9, 2024 · China''s battery production capacity grew 56% year-over-year in 2023, reaching 1,200 GWh, with Tier 2 battery manufacturers accelerating automated formation line

Get Started

Additional options for battery box | Automatic

Expand your Batteryguard battery cabinet with additional options | Automatic extinguishing system with cooling extinguishing foam | 400-volt power connection

Get Started

What are the types of battery capacity distribution cabinets

Nickel hydrogen battery capacity divider: mainly used for capacity division testing of nickel hydrogen batteries. Due to the different charging and discharging characteristics of nickel

Get Started

Battery assembly solution

Aug 19, 2025 · JOT Automation''s expertise in battery assembly automation allows us to deliver customized solutions tailored to your production needs. Our

Get Started

Cabinets (Kitchen/Bath/Storage)

We build the machines to make woodworking automated production lines more efficient, including wood panel feeding and stacking systems to make cabinets

Get Started

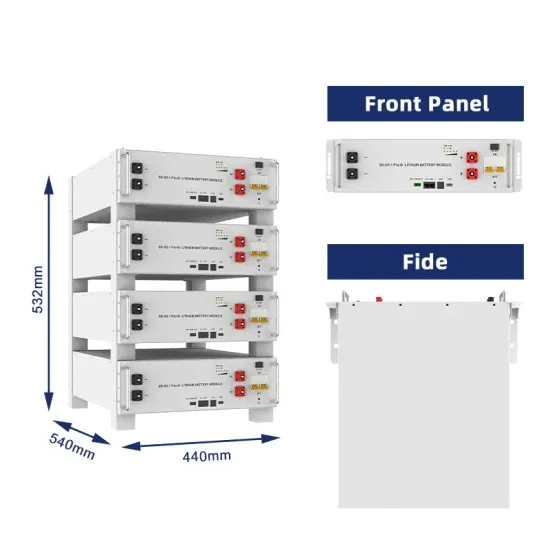

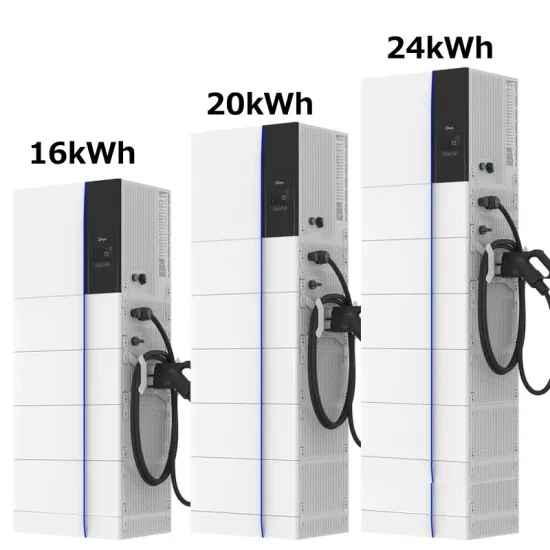

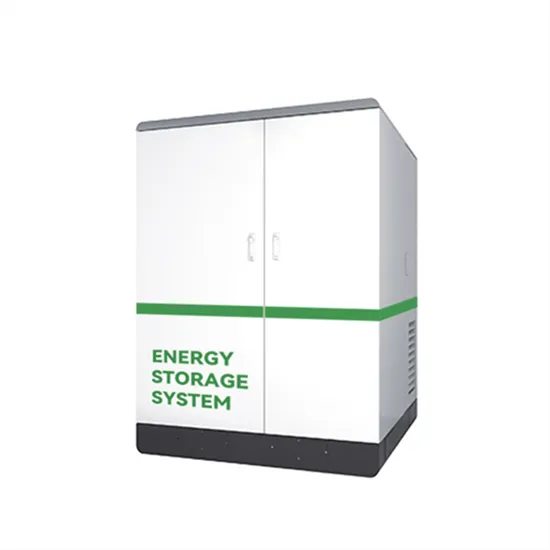

What Are Battery Rack Cabinets and Why Are They Essential?

Jun 15, 2025 · Battery rack cabinets are modular enclosures designed to securely house and organize multiple batteries in industrial, telecom, or renewable energy systems. They optimize

Get Started

Top Battery Formation Cabinets by Wangsheng

May 22, 2025 · Optimize your battery manufacturing process with Battery Formation Cabinets from Dongguan Wangsheng Automation Equipment Co., Ltd. As industry leaders, we provide

Get Started

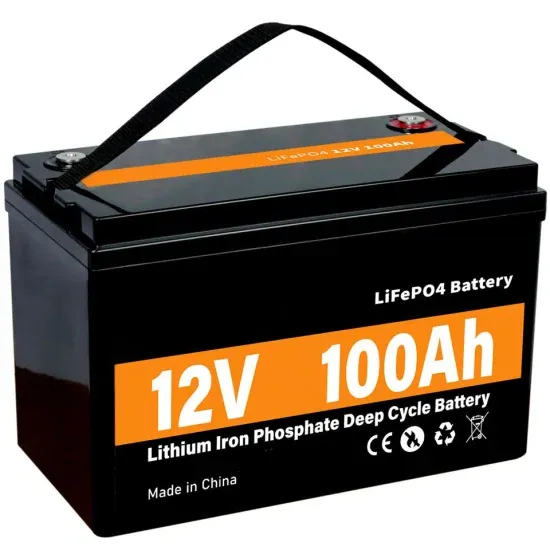

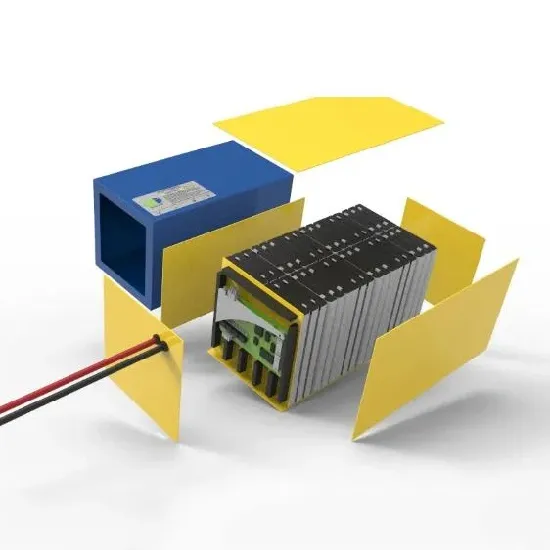

Lithium battery module design production

Aug 18, 2025 · This article will introduce you to the characteristics, design and production process, key points, and development trend of lithium battery

Get Started

Automated battery manufacturing

A new production process and a larger lithium-ion cylindrical cell size is aiming to drive the automated manufacturing of battery cells; its design is key to scaling

Get Started

Battery cabinet for safely charging lithium-ion

Charge your lithium-ion batteries safely in a battery cabinet | Batteryguard contains battery fires within the safe | European tested and approved

Get Started

6 FAQs about [Automated production of battery cabinets]

What is the future of battery manufacturing?

The global battery manufacturing industry is in the midst of an evolution driven by advanced automation, AI and the rapid rise in EV and energy storage demand. This blog examines the current landscape of battery manufacturing, highlighting key challenges, transformative use-cases, and advanced solutions shaping the industry's future.

Why is battery assembly important?

In the competitive world of electric vehicles and energy storage, efficient and precise battery assembly is crucial for meeting high performance and safety standards. At JOT Automation, we provide cutting-edge solutions for battery module assembly and battery pack assembly, ensuring seamless integration and optimized production.

What is a battery assembly solution?

The comprehensive Battery Assembly solution can be equipped with an array of options, including unpacking, waste disposal, electrical testing, enclosure and casing assembly, PCB assembly, laser welding and final-product testing. Plus the solution's compartmentalized design ensures high-grade fire safety to keep its processes and surroundings safe.

How is Ai transforming the battery industry?

Advanced manufacturing solutions driven by AI and automation are setting new standards in the battery industry, offering both established and emerging players the tools to meet the demands of a rapidly evolving market.

What is the Jot battery assembly solution?

Watch the JOT Battery Assembly Solution in action. JOT Automation’s industry-leading battery assembly solution is a fully complete, turnkey solution for battery assembly that is also EV battery compatible. Highlights include automated unpacking of incoming material, testing, welding applications and final-product testing.

What is the future of high-precision battery manufacturing?

AI platforms like LEADACE represent the future of high-precision battery manufacturing. These platforms employ self-learning algorithms to adjust parameters in real-time, minimizing the need for human intervention and ensuring a consistent output.

Related Articles

-

Principles of mass production of battery cabinets

Principles of mass production of battery cabinets

-

Lithium battery production using ladder tools

Lithium battery production using ladder tools

-

Battery energy storage system production in San Salvador

Battery energy storage system production in San Salvador

-

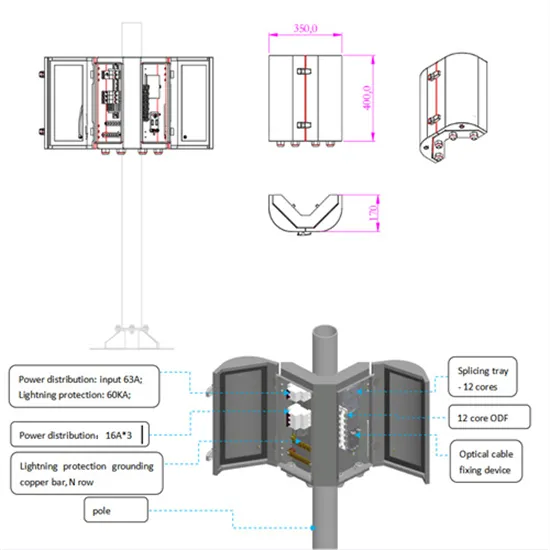

Production of battery ESS power base station container

Production of battery ESS power base station container

-

Lithium-ion Battery Cabinets and Systems

Lithium-ion Battery Cabinets and Systems

-

Congo Lithium Battery Production Company

Congo Lithium Battery Production Company

-

Advantages and Disadvantages of Commercial Energy Storage Battery Cabinets

Advantages and Disadvantages of Commercial Energy Storage Battery Cabinets

-

How much does a battery cabinet production line cost per day

How much does a battery cabinet production line cost per day

-

Tallinn Communication Base Station Battery Production

Tallinn Communication Base Station Battery Production

-

Are there many energy battery cabinets at the Korean site

Are there many energy battery cabinets at the Korean site

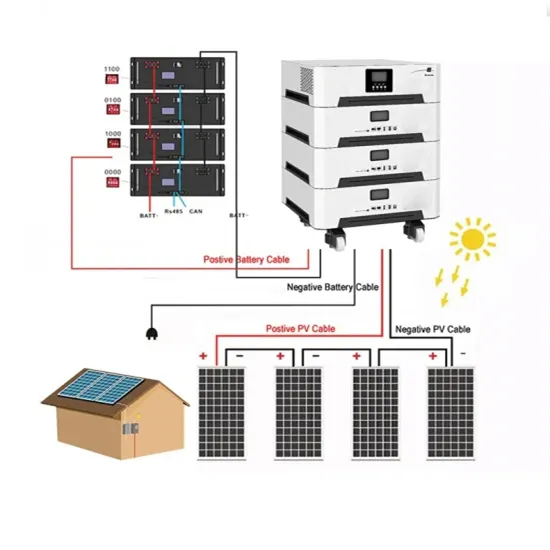

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.