Battery Cabinet

Mar 21, 2023 · SmartLi 2.0 is a self-developed battery energy storage system solution. It provides a cabinet-level battery management system and supports a maximum of 15 cabinets

Get Started

Assembly line for battery modules and battery packs

6 days ago · For cell/module pack assembly, PIA Automation offers flexible and highly automated systems for the efficient production of battery cells, modules, and battery packs. These

Get Started

Automation of Operations in Assembly of Battery Modules in

Jan 1, 2024 · By employing robots and other automation technologies, the assembly process can be streamlined, reducing bottlenecks, and minimizing the risk of error and electrocution. This

Get Started

Battery Module

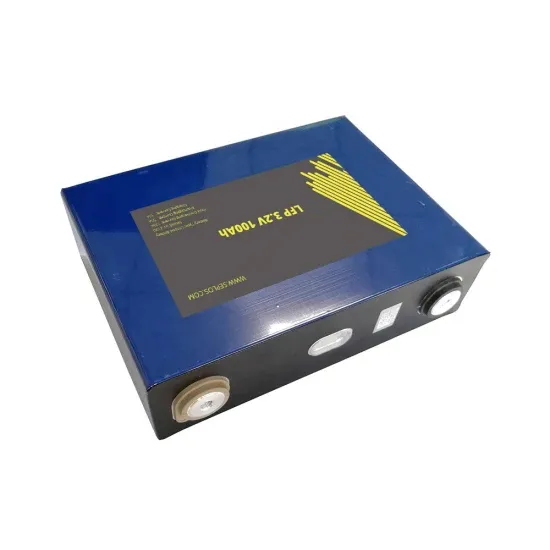

A battery module has 40 lithium iron phosphate cells (two parallel strings, each consisting of 20 cells connected in series). The built-in BMU manages battery balance, measures common

Get Started

SmartLi UPS | Lithium Battery UPS | Ups Battery

Huawei SmartLi Lithium Battery UPS provides reliable, high-performance energy storage, offering scalable and efficient backup power solutions for critical

Get Started

battery module pack automatic production lines

The Prismatic Battery Pack Assembly Line integrates a variety of automated equipment and technologies, mainly covering the entire process from module assembly to the final battery

Get Started

Energy Storage Solution (ESS) | HUAWEI Smart

Huawei''s Smart String Grid-Forming ESS ensures robust protection through five layers of integrated safety design, from individual cells, battery packs, racks,

Get Started

Lithium Battery Module Pack Assembly Line

A Lithium Battery Module PACK Assembly Line is a production line designed to assemble individual lithium battery cells into modules and then further assemble these modules into

Get Started

LUNA2000-97/129/161/200KWH | Smart String

The SOC will automatically synchronize with the existing battery packs after a battery pack replacement. Remote faulty module detection free the system

Get Started

Working Principles

The MBUS CCO module is available only for the SmartACU2000D-D-02. The figure displays only major components and cables, and is for reference only. Ethernet communication mode All

Get Started

Battery Manufacturing Automation From Bosch

Bosch Rexroth is accelerating battery manufacturers'' speed to market with the industry''s most complete battery manufacturing automation solution.

Get Started

Energy storage module pack automatically

What is a battery module automation production line? Our battery module automation production line stands at the forefront of advanced manufacturing technology,designed to streamline and

Get Started

LUNA2000 battery system specifications

The LUNA2000 battery system specifications provide detailed information on product models, conversion efficiency, input/output specifications, safety standards, and other relevant details.

Get Started

Battery Module & Pack Manufacturing: Step-by

Apr 19, 2025 · As India and other emerging markets ramp up battery pack assembly, the global blueprint is clear: automation, flexibility, and integrated

Get Started

SmartLi UPS | Lithium battery UPS in Singapore

Jul 1, 2025 · SmartLi Huawei SmartLi is a Huawei-developed battery energy storage system solution that provides backup power for medium- and large

Get Started

Installing Battery Packs

Aug 1, 2025 · At least four persons are required to move a battery pack. Secure the lifting handles (with the steel washers of the lifting handles closely fitted to the battery pack).

Get Started

Lead-Acid Battery Pack

Jul 17, 2025 · Each battery pack consists of twenty 12 V, 7 Ah/9 Ah lead-acid batteries connected in series. It is a standard configuration for the 6 kVA and 10 kVA UPSs. A maximum of four

Get Started

LUNA2000-215 Series: Smart Energy Storage

Discover the Huawei LUNA2000-215 Series, a smart and efficient energy storage solution for your home. Enhance your solar energy system with reliable

Get Started

ESS-240V12-9AhBPVBA03 Modular Battery Pack Quick Guide

Jan 18, 2019 · This document describes how to install battery packs for a 6 kVA UPS. 1. The two battery ports on a battery pack have been connected in parallel inside. Do not connect. them

Get Started

4 Replacing a Battery Pack

Before replacing a battery pack, ensure that the ESS is powered off. Otherwise, electric shocks may occur. Wear personal protective equipment and use dedicated insulated tools to avoid

Get Started

BCU

Old and new battery strings can be used together, ensuring reliable system operation. Implements intra-cabinet and inter-cabinet communication, collects sampling signals from battery modules,

Get Started

Automatic EV Battery and Storage Battery Dual Purpose Module Pack

Aug 6, 2025 · Shenzhen Bluesea Intelligent Manufacturing Technology Co., LTD., founded in 2016, is an overall intelligent manufacturing solution supplier focusing on the research and

Get Started

What Are Battery Cells, Battery Modules, And

Feb 23, 2024 · Here we''ll talk about the differences between battery cells, modules, and packs, and learn how to tell these key components for effective

Get Started

Huawei LUNA2000-10-S0 battery storage 10

Huawei LUNA2000-10-S0 battery storage 10 kWh Can be expanded at any time thanks to the modular design from 10 to 30 kWh 100% Usable (DoD) Each

Get Started

Energy Storage Solution (ESS) | HUAWEI Smart

Cell to Grid Safety Huawei''s Smart String Grid-Forming ESS ensures robust protection through five layers of integrated safety design, from individual cells,

Get Started

Huawei LUNA2000 DCDC control module

Aug 7, 2025 · The Huawei LUNA2000 DCDC control module is used to build an intelligent energy storage system using the Huawei Luna2000 power bank.

Get Started

SmartLi 2.0 User Manual

Purpose This document describes the SmartLi 2.0 intelligent lithium battery cabinet (lithium battery cabinet for short) in terms of its overview, transportation, storage, installation, cable

Get Started

Battery Cabinet

A maximum of three battery groups in up to six battery cabinets can be deployed inside the smart module. If many batteries are configured, they can be deployed outside the smart module. If

Get Started

EV Battery Pack Assembly

EV battery pack assembly is an essential part of battery production automation. Making up up to 60% of the cost of an electric vehicle (EV), the battery is the

Get Started

Automated battery manufacturing

The battery housing is then covered with a heat-sealed lid to make the battery module safe to touch and protect it from dust. Finally, a Data Matrix code is

Get Started

6 FAQs about [Huawei battery module pack automation]

How many cells are in a battery module?

A battery module has 40 lithium iron phosphate cells (two parallel strings, each consisting of 20 cells connected in series). The built-in BMU manages battery balance, measures common data such as battery voltage and temperature, generates alarms, and implements CAN communication between battery modules. The battery module is normal.

How do pack assembly modules work?

3. Pack Assembly Modules are stacked in series and parallel configurations to form a complete pack. A master BMS, structural supports, and thermal management components are added. The pack is enclosed in a robust casing to ensure durability and safety.

What is a 3 layer battery management system (BMS)?

The three-layer battery management system (BMS) ensures the reliability of lithium batteries. A built-in fire extinguisher is used. Before the BCB switch is turned on, the SmartLi can automatically detect the insulation impedance of the positive and negative battery terminals to PE, ensuring safe startup and operation.

How long does a smartli battery backup take?

The backup time can be 15 minutes, 30 minutes, 1 hour, 2 hours, or 4 hours, depending on the capacity of the SmartLi 2.0 lithium battery cabinet. A maximum of 15 SmartLi 2.0 lithium battery cabinets can be connected in parallel. When multiple cabinets are connected in parallel, only the master cabinet has an LCD.

Can a battery cabinet be deployed outside a smart module?

Battery cabinets or racks can also be deployed outside smart module A (batteries deployed outside) or smart module B. The front door is a single door, and the rear door is a double one. Shoto batteries are supported.

Can a battery module be charged or discharged?

As a result, the battery modules cannot be charged or discharged. Start the air conditioner to heat the battery modules to 3°C or above, and the charge and discharge will be resumed. Note: N indicates the number of battery modules connected in series.

Related Articles

-

Lithium battery pack external module

Lithium battery pack external module

-

Huawei Tallinn energy storage battery pack manufacturing

Huawei Tallinn energy storage battery pack manufacturing

-

Difference between battery module and pack

Difference between battery module and pack

-

Huawei Estonia cylindrical battery pack factory

Huawei Estonia cylindrical battery pack factory

-

Pack automation battery

Pack automation battery

-

Huawei Liberia energy storage battery pack customization

Huawei Liberia energy storage battery pack customization

-

Huawei Iran lithium battery pack

Huawei Iran lithium battery pack

-

Huawei Norway Bergen cylindrical power battery pack

Huawei Norway Bergen cylindrical power battery pack

-

Bolivia battery module PACK

Bolivia battery module PACK

-

New energy battery pack module

New energy battery pack module

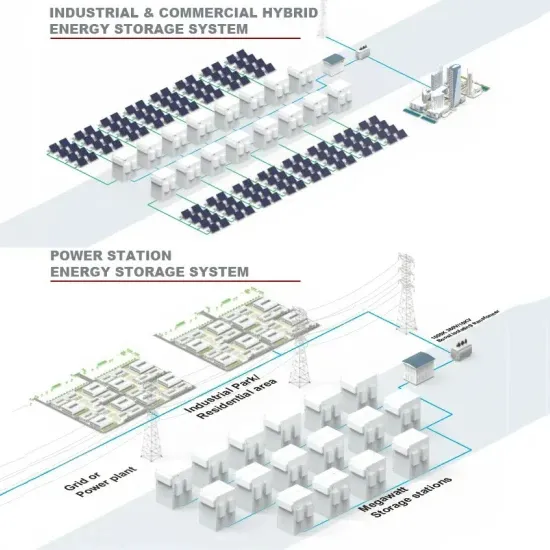

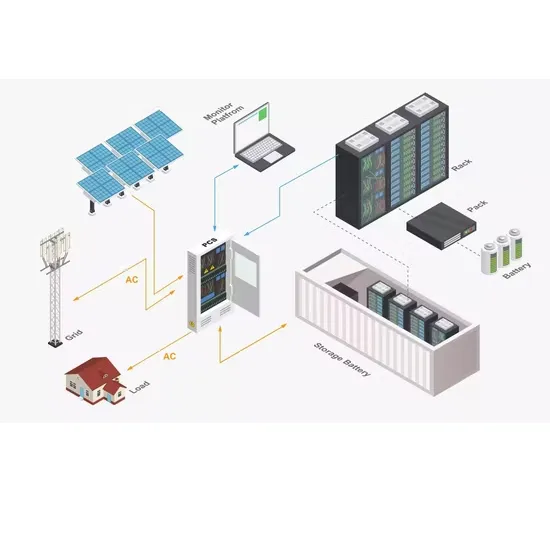

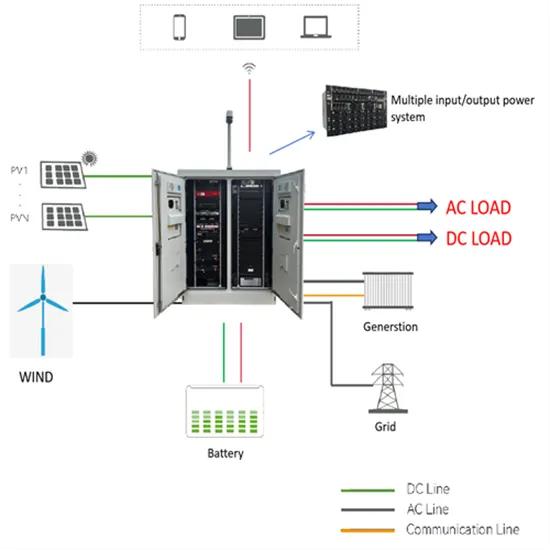

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

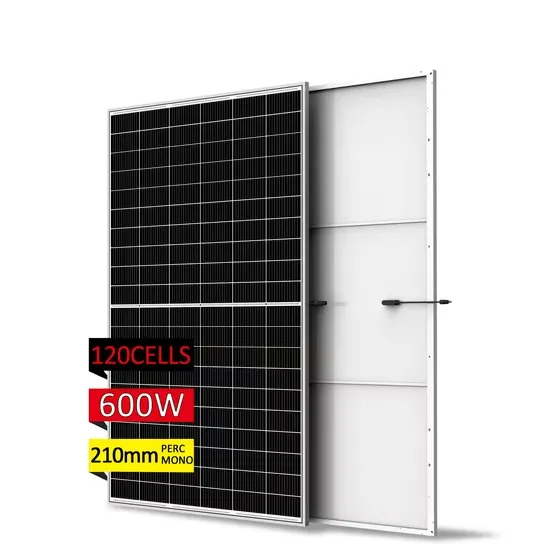

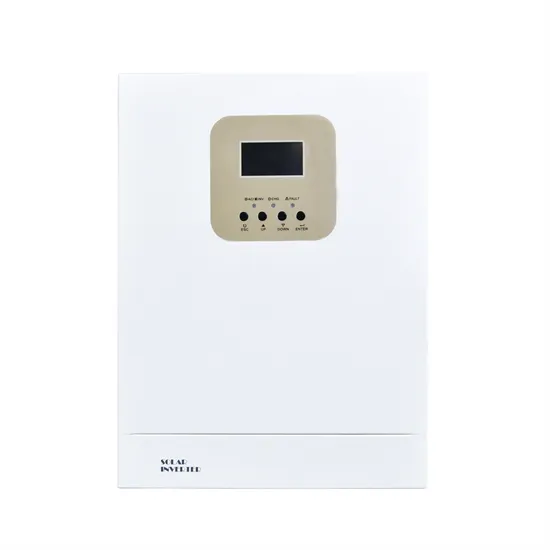

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.