What Is An Inverter Welding Machine

Feb 20, 2025 · An inverter welding machine is a type of welding equipment that uses advanced inverter technology to convert AC mains power to high-frequency DC power. This conversion

Get Started

High Capacity Industrial Power Inverter

1 day ago · We are best suppliers of industrial power inverters with a 5KVA to 600KVA range, IGBT with microcontroller-based, highly useful for industrial &

Get Started

Understanding inverter frequency – effects and

Oct 1, 2024 · In today''s world, inverters play a vital role in various applications, such as home solar power system, inverter for office use, inverter for van, etc.

Get Started

Harmonic Overload: Impacts Of High-Frequency

5 days ago · During the CIGRE Grid of the Future symposium and workshop, harmonics were recognized as a critical focus in modern electrical systems,

Get Started

High Frequency Inverter for Industrial Applications

High frequency inverters play a critical role in modern industrial applications, converting DC power into high-frequency AC power for a wide range of machinery and equipment. These inverters

Get Started

Industrial frequency inverter, Industrial

Find your industrial frequency inverter easily amongst the 68 products from the leading brands (Bonfiglioli, NORD, INVT,) on DirectIndustry, the industry

Get Started

Medium frequency and high frequency DC inverter

Apr 2, 2025 · Small size and light weight: high-frequency core materials greatly reduce the size, making medium-frequency inverter resistance welding transformer easy to carry and install.

Get Started

A High Frequency Inverter for Variable Load Operation

Sep 27, 2018 · Inverters operating at high frequency (HF, 3-30MHz) are important to numerous industrial and commercial applications such as induction heating, plasma generatio

Get Started

Teach you how to choose industrial frequency inverter and high

Structurally, the difference between industrial frequency inverters and high frequency inverters is mainly reflected in the isolation transformer, and the use of isolation transformers by industrial

Get Started

High Frequency MMA-300 Digital Inverter Dc Arc Welding Machine

Product descriptions from the supplier Specification Name Portable Small Welder Inverter Welding Machines Model Number: MMA-300 Rated Input Voltage: 220V Max.Load Power

Get Started

INVERTER WELDING MACHINES AND

This range includes a standard DC inverter, high frequency AC/DC tig welding unit, synergic pulse mig unit and pipeline specific machines which were

Get Started

What is the difference between an industrial frequency

Jun 18, 2025 · The power frequency compressor provides the base load, and one (or more) inverter compressors are "fine-tuned" to meet changes in demand.What are the benefits of

Get Started

Inversion Methods Explained: High Frequency vs Low Frequency

4 days ago · There are two distinct types of industrial grade power inverters distinguished by the size of their transformers, and the switching speed of their transistors. The ability of an inverter

Get Started

Industrial Frequency Converter Manufacturer, Custom Inverter

According to the characteristics of various industries, MICNO industrial frequency converter has designed specific structure and function to provide safe, stable, and flexible products and

Get Started

Frequency inverters

Mar 4, 2022 · High quality frequency inverters for electric motor speed controls in energy-saving solutions. Save your time, state your applications and send an

Get Started

The difference between power frequency

Aug 3, 2021 · (3) Both the industrial frequency machine and the high frequency machine adopt an online structure, that is, the inverter circuit in the machine is

Get Started

The difference between industrial frequency inverter and high frequency

Jan 6, 2021 · The power frequency machine and the high frequency machine are distinguished according to the design circuit operating frequency of the inverter. The power frequency

Get Started

Top Industrial Frequency Inverters Compared for 2025

Compare top frequency inverter models for 2025, including Hitachi SJ-P1, Mitsubishi FR-A800, and more. Discover their performance, efficiency, and ROI insights.

Get Started

High-Frequency Inverter: How They Work and

3 days ago · High-frequency, high-power inverters are suitable for commercial and industrial use. The large capacity can power high-load electronic devices

Get Started

Understanding Frequency Inverters: A Comprehensive Guide

Feb 23, 2025 · A frequency inverter, also known as a variable frequency drive (VFD), is an essential device used to control the speed and torque of electric motors by adjusting the input

Get Started

Power frequency machine and high frequency

Jul 30, 2021 · In the inverter circuit of the industrial frequency machine, there is a synthetic transformer, also called the output transformer. The synthetic

Get Started

Medium frequency and high frequency DC inverter

Apr 2, 2025 · Due to their different frequency characteristics, medium-frequency DC inverter transformers and high-frequency DC inverter transformers are suitable for industrial heating,

Get Started

UPS Machine Types Low-Frequency vs High-Frequency Guide

Jun 6, 2025 · In the field of Uninterruptible Power Supplies (UPS), low - frequency and high - frequency machines shine like two distinct stars, each with its own unique attributes. For

Get Started

Power Frequency Inverter vs. High Frequency

May 15, 2024 · High frequency inverter: High frequency inverters use high-frequency switching technology to chop DC power at high frequency through

Get Started

Machine frequency inverter

Find your machine frequency inverter easily amongst the 28 products from the leading brands (Bonfiglioli, NORD, ZIEHL-ABEGG,) on DirectIndustry, the industry specialist for your

Get Started

What is an Inverter Welder? How Inverter

Jul 15, 2025 · An inverter welder is a type of welding machine that uses advanced electronic technology to convert electrical power into a high-frequency output,

Get Started

Industrial UPS & High Frequency UPS & Modular

Jan 4, 2020 · The high-frequency tower machine can only achieve 94 ~ 95% efficiency under this working condition, and the mainstream modular UPS

Get Started

Comparative Investigation of PWM Current-Source

May 16, 2024 · Comparative Investigation of PWM Current-Source Inverters for Future Machine Drives using High-Frequency Wide-Bandgap Power Switches

Get Started

High-power UPS industrial frequency and high-frequency machines

1 Definition and principle analysis of industrial frequency machine and high frequency machine UPS is usually divided into two types: power frequency UPS and high frequency UPS. The

Get Started

6 FAQs about [Industrial frequency machine and high frequency machine inverter]

What is a high frequency inverter?

High frequency inverter: High frequency inverters use high-frequency switching technology to chop DC power at high frequency through high-frequency switching tubes (such as IGBT, MOSFET, etc.), and then convert high-frequency pulses into stable alternating current through high-frequency transformers and filter circuits.

What are the advantages of high frequency inverters?

Volume and weight: Since high frequency inverters use high-frequency switching technology and compact circuit design, their size and weight are usually much smaller than power frequency inverters. This gives high frequency inverters significant advantages in mobile power supplies, aerospace, electric vehicles, and other fields.

How does a power frequency inverter work?

Its working principle is to convert DC power into AC power with the same frequency and phase as the power grid through an internal power conversion circuit. Power frequency inverters mostly use traditional components such as transformers and inductors to convert voltage and current.

Are high-frequency inverters a good choice?

Due to the use of high-frequency switching technology, high-frequency inverters have the advantages of small size, lightweight, and high efficiency, but they also have the problem of relatively poor output waveform quality.

Are power frequency inverters good?

In contrast, power frequency inverters can maintain high efficiency and stability under heavy load or overload. Output waveform quality: The output waveform quality of power frequency inverters is usually better than that of high frequency inverters.

What is the difference between a low frequency and high frequency inverter?

Low-frequency inverter: heavy and capable of surge power, lower efficiency, more reliable, expensive. High-frequency inverter: lightweight, not capable of surges, more efficient, less reliable, cheaper. I’m an off-grid enthusiast.

Related Articles

-

Household high frequency or industrial frequency inverter

Household high frequency or industrial frequency inverter

-

The difference between inverter high frequency and industrial frequency

The difference between inverter high frequency and industrial frequency

-

Is a high frequency machine an inverter

Is a high frequency machine an inverter

-

Astana 48v industrial frequency inverter

Astana 48v industrial frequency inverter

-

High frequency inverter in Douala Cameroon

High frequency inverter in Douala Cameroon

-

Industrial frequency inverter connected to DC power

Industrial frequency inverter connected to DC power

-

High frequency sine wave inverter

High frequency sine wave inverter

-

High frequency inverter price in Pakistan

High frequency inverter price in Pakistan

-

High frequency inverter charging

High frequency inverter charging

-

Stockholm High Frequency Inverter Installation

Stockholm High Frequency Inverter Installation

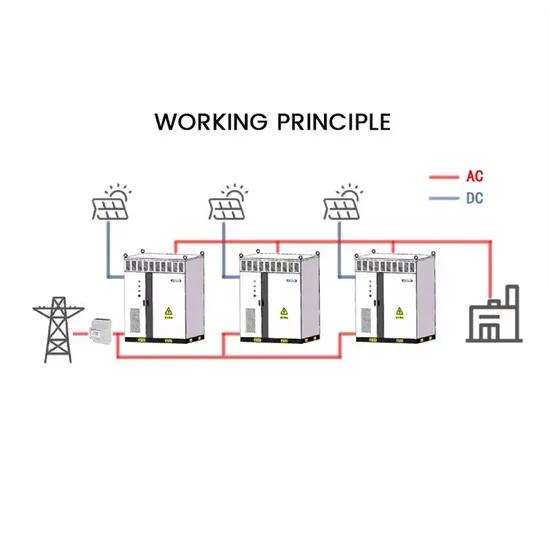

Commercial & Industrial Solar Storage Market Growth

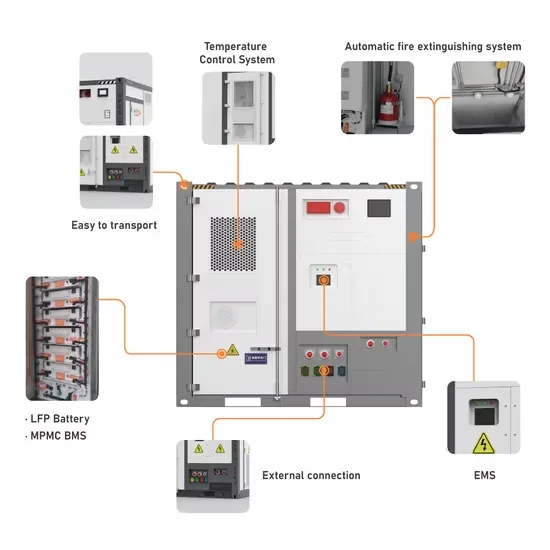

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

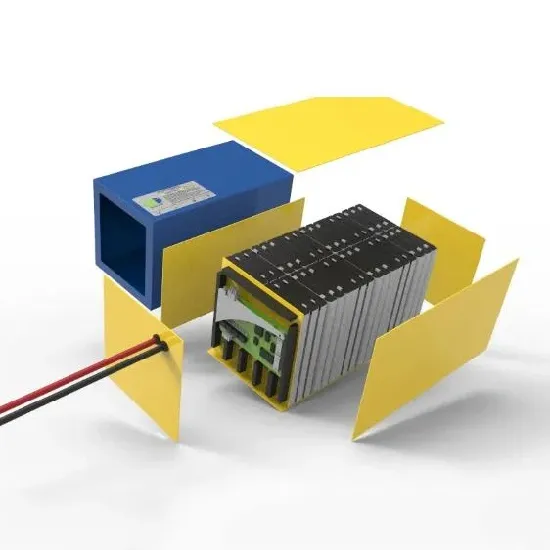

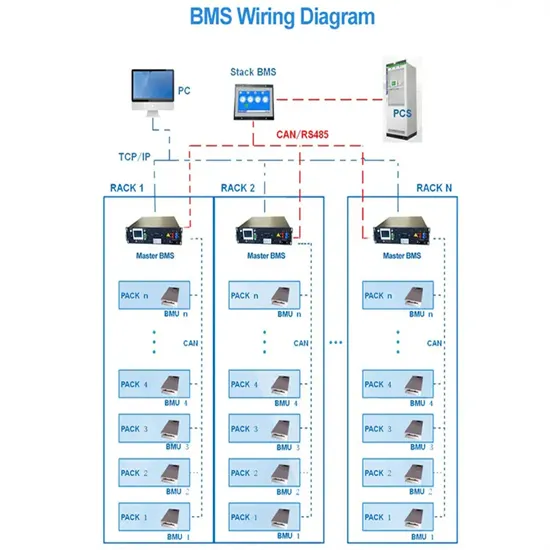

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.