Frequency Converter vs Inverter

Oct 22, 2024 · Both frequency converters and inverters play critical roles in modern electrical systems, but they serve different purposes. Frequency converters are essential for

Get Started

Which is Better: Low Frequency or High Frequency Inverter?

Mar 20, 2025 · You need a cost-effective solution that still delivers high efficiency. You want a portable, compact inverter for backup power or mobile systems. Conclusion Both low

Get Started

Frequency Inverter Basic: Introduction, Functions

Dec 11, 2023 · Function of Frequency Inverter Speed Regulation Function: Frequency inverters can change the speed of the motor by adjusting the

Get Started

Low Vs High Frequency Inverters/UPS Comparison

Oct 26, 2024 · Understanding the differences between high-frequency and low-frequency inverters is vital for anyone involved in renewable energy or considering an uninterrupted

Get Started

Classification and Functional Role of Frequency Converter

Dec 22, 2024 · 5.according to the number of control classification: inverter can be divided into single inverter and multi-inverter two types. Single inverter can only control a motor, multi

Get Started

Frequency Inverter | inverter

0.75kW single phase output frequency inverter for sale, 1-phase input to 0~input voltage 1-phase output at 220V/230V/240V. Rated current 7A, input voltage single phase AC 220 ± 15%, and

Get Started

How Does An Inverter Work? | Its Components,

Jan 25, 2025 · The inverter uses electronic components like oscillators, transistors, and transformers to switch the DC power into a high-frequency

Get Started

Technical comparison between Low Frequency

Aug 19, 2025 · What internal frequency the inverter circuits operate at – low frequency or high frequency (not to be confused with AC power output

Get Started

Frequency inverters

The tasks and function of a frequency inverter are varied depending on the model, for example the " frequency inverter 400v " or " frequency inverter 230v ", and

Get Started

High-Frequency vs. Low-Frequency Inverters

High-Frequency Inverters: High-frequency inverters are generally more efficient in terms of energy conversion, with efficiencies ranging from 90% to 96%. They can operate with less power loss

Get Started

Low Vs High Frequency Inverters/UPS Comparison

In the world of renewable energy and uninterrupted power systems, inverters play a crucial role in converting direct current (DC) to alternating current (AC), which is essential for powering most

Get Started

Low vs. High-Frequency Inverters/UPS: A

Dec 6, 2024 · High-Frequency Inverters/UPS These are transformer less and lightweight systems optimized for efficiency. Their advanced technology allows

Get Started

Learn About High vs. Low Frequency Inverters:

Feb 10, 2025 · An inverter is a key component that converts DC power into AC power for household appliances and is commonly used in solar energy

Get Started

High-Frequency Inverter: How They Work and

3 days ago · High-frequency, high-power inverters are suitable for commercial and industrial use. The large capacity can power high-load electronic devices

Get Started

Power Inverters: What Are They & How Do They

Dec 17, 2019 · Key learnings: Inverter Definition: An inverter is defined as a power electronics device that converts DC voltage into AC voltage, crucial for

Get Started

Technical comparison between Low Frequency

Aug 19, 2025 · Low-frequency inverters have the advantage over high-frequency inverters in two fields: peak power capacity, and reliability. Low-frequency

Get Started

Which is Better: Low Frequency or High Frequency Inverter?

Mar 20, 2025 · If you are looking for a reliable, durable, and efficient hybrid inverter for high-power applications, such as powering a whole home or industrial equipment, a low-frequency inverter

Get Started

What is the Purpose of an Inverter in Off-grid

Feb 2, 2025 · The efficiency of inverters typically ranges between 80% and 90%, depending on factors such as circuit design and battery type. High-frequency

Get Started

Industrial inverter vs household inverter

May 4, 2024 · Energy saving and environmental protection: industrial grade inverter has high energy conversion efficiency, which can better reduce

Get Started

What is the difference between a high frequency

Apr 25, 2024 · Since the high-frequency inverter uses small-sized, lightweight high-frequency magnetic core materials, the power density of the circuit is

Get Started

What Makes Low Frequency Inverters Unique

Low frequency inverters offer durability, high surge capacity, and low EMI, making them ideal for heavy-duty applications, off-grid systems, and sensitive devices.

Get Started

The difference between a high and low frequency inverter

2. Low Frequency Inverters: Robust and Durable: Low frequency inverters are better suited for applications requiring high power output and reliability. Their robust design allows them to

Get Started

Energy Storage Batteries: High vs. Low Frequency Inverters

May 28, 2025 · In household solar systems, energy storage batteries paired with inverters are essential for converting stored DC power into usable AC power for appliances. Inverters come

Get Started

Power Frequency Inverter vs High-Frequency Inverter

Nov 14, 2024 · If you are looking for an inverter for fixed power stations, precision instruments, or other related fields, then go with power-frequency inverters. However, a high-frequency

Get Started

Which is better, power frequency inverter or high-frequency inverter?

Sep 20, 2024 · Industrial frequency inverters have strong resistance to impact loads, and overload and short-circuit protection are easier to make than high-frequency inverters. However, high

Get Started

Power Frequency Inverter vs. High Frequency

May 15, 2024 · In the field of power electronics and energy conversion, inverters, as key equipment for power conversion, play a vital role. Inverters are capable

Get Started

Top Industrial Frequency Inverters Compared for 2025

Compare top frequency inverter models for 2025, including Hitachi SJ-P1, Mitsubishi FR-A800, and more. Discover their performance, efficiency, and ROI insights.

Get Started

Understanding Frequency Inverters: A Comprehensive Guide

Feb 23, 2025 · A frequency inverter, also known as a variable frequency drive (VFD), is an essential device used to control the speed and torque of electric motors by adjusting the input

Get Started

Key Differences Between Frequency Inverters and Inverters

Dec 3, 2024 · When should I choose a low-frequency inverter over a high-frequency inverter? You should choose a low-frequency inverter when your application requires handling heavy loads

Get Started

6 FAQs about [Household high frequency or industrial frequency inverter]

What are high-frequency inverters used for?

High-frequency inverters are versatile and are used in a wide range of applications. They are particularly popular in solar power systems, where efficiency and compact design are crucial. Additionally, they are found in: Uninterruptible Power Supplies (UPS) for quick response times during power outages.

What is the difference between low frequency and high frequency inverters?

In fact, low frequency inverters can operate at the peak power level which is up to 200% of their nominal power level for several seconds, while high-frequency inverters can operate at 150% power level for a small fraction of a second.

What internal frequency do inverters operate at?

What internal frequency the inverter circuits operate at – low frequency or high frequency (not to be confused with AC power output frequency which is a standard 50Hz for our inverters). Low-frequency inverters have the advantage over high-frequency inverters in two fields: peak power capacity, and reliability.

How do I choose a high-frequency or low-frequency inverter?

Choosing between a high-frequency and low-frequency inverter depends on several factors, including efficiency, size, budget, and application needs. Here’s a quick guide: Residential Users: High-frequency inverters are ideal for home use, especially in solar systems, due to their efficiency and compact size.

What is a high frequency inverter welding machine?

The inverter circuitry can also provide features such as power control and overload protection. The high frequency inverter-based welding machines are typically more efficient and provide better control of variable functional parameters than non-inverter welding machines.

How much does a high frequency inverter weigh?

That unit (Phocos PSW-H 5kw/120v) weighs around 110 lbs. I'm also considering it for my off-grid build, but I believe high frequency inverters generally weigh less and can double power on a surge for a couple seconds.

Related Articles

-

The difference between inverter high frequency and industrial frequency

The difference between inverter high frequency and industrial frequency

-

High frequency power supply and industrial frequency inverter

High frequency power supply and industrial frequency inverter

-

Industrial frequency and high frequency inverter for RV

Industrial frequency and high frequency inverter for RV

-

Inverter high frequency vibration

Inverter high frequency vibration

-

Sri Lanka 48v industrial frequency inverter

Sri Lanka 48v industrial frequency inverter

-

Huawei industrial frequency inverter 20kw

Huawei industrial frequency inverter 20kw

-

Household inverter high power 12000w

Household inverter high power 12000w

-

High frequency inverter front stage module

High frequency inverter front stage module

-

High frequency inverter 100w

High frequency inverter 100w

-

How many k is the best for high frequency inverter potentiometer

How many k is the best for high frequency inverter potentiometer

Commercial & Industrial Solar Storage Market Growth

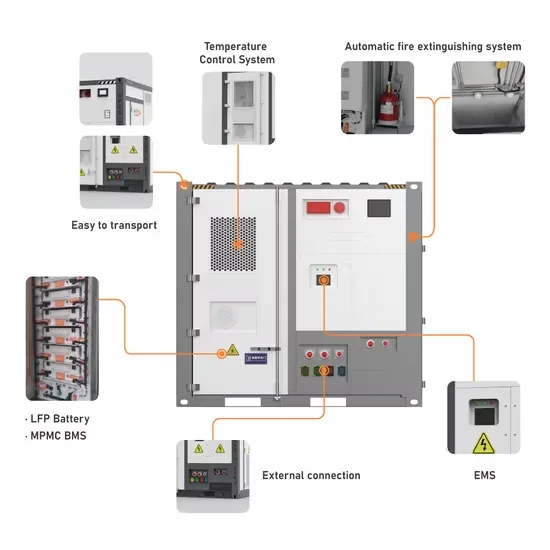

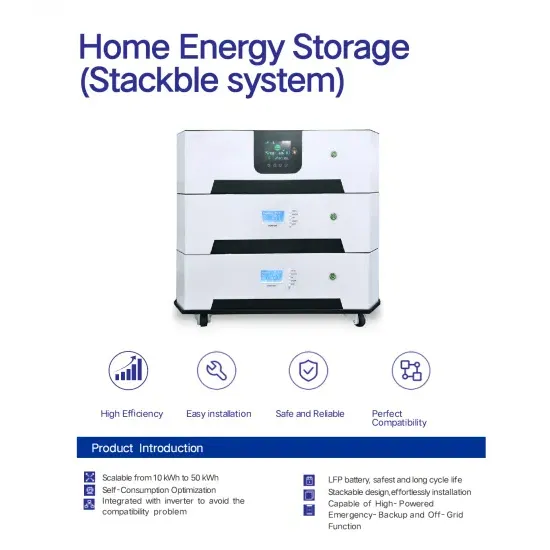

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.