High-frequency sine wave inverter specially

Sep 21, 2022 · As a high-frequency inverter, BPlus also has 3 times peak power, which can better support the various equipment in RVs. Peak power will be

Get Started

Home Auto RV Pure Sine Wave 24V DC to 220V AC Industrial

Oct 25, 2024 · Home Auto RV Pure Sine Wave 24V DC to 220V AC Industrial 250W to 5000 Watt High Frequency Drive Solar Panel Power Wind Micro Inverter System for Car and Boat, Find

Get Started

24VDC 400W to 2000W High Frequency Converter for RV

Apr 2, 2025 · 24VDC 400W to 2000W High Frequency Converter for RV, Find Details and Price about Inverter High Frequency Inverter from 24VDC 400W to 2000W High Frequency

Get Started

Understanding High-Frequency Inverters

6 days ago · In the realm of power electronics, the advent of high-frequency inverters has revolutionized the landscape. These enigmatic devices possess the uncanny ability to

Get Started

Inversion Methods Explained: High Frequency vs Low Frequency

4 days ago · The large majority of inverters available in the retail market are high frequency. They are typically less expensive, have smaller footprints, and have a lower tolerance for industrial

Get Started

ZLPOWER 4000W 24V DC Pure Sine Wave

Nov 23, 2024 · ZLPOWER 4000W 24V DC Pure Sine Wave Inverter, 12000W Peak, 120V/240V AC Split Phase Output with Battery Charger, LCD Display,

Get Started

3kw High-Frequency Pure Sine Wave Inverter for RV

RVI series is a new inverter and charger for RV, which integrates mains charging energy storage and AC sine wave output. With High efficiency mains charging mode. Two output modes are

Get Started

Power Frequency Inverter vs. High Frequency

May 15, 2024 · In the field of power electronics and energy conversion, inverters, as key equipment for power conversion, play a vital role. Inverters are capable

Get Started

Low Frequency VS High Frequency Inverter

May 2, 2023 · Discover the differences between low-frequency and high-frequency off-grid inverters, their efficiency, weight, and ideal applications for

Get Started

What are the Types of Frequency Inverter?

Oct 22, 2023 · These frequency converters are typically used in low-power applications and high-frequency applications. Frequency inverters are

Get Started

Understanding the Difference Between

Jan 21, 2025 · Choosing between a frequency inverter and a high-frequency inverter depends on your specific needs—whether you''re looking for power

Get Started

POWER WHE

Jul 22, 2025 · Whether it''s large appliances, essential medical devices, or high-performance equipment, AIMS Power''s industrial-grade inverters ensure seamless and eficient operation in

Get Started

Influence of Wideband Cable Model for Electric

Feb 27, 2025 · Electric vehicles (EVs) rely on robust inverter-to-motor connections to ensure high-efficiency operation under the challenging

Get Started

Which is better, power frequency inverter or high-frequency inverter?

Sep 20, 2024 · Industrial frequency inverters have strong resistance to impact loads, and overload and short-circuit protection are easier to make than high-frequency inverters. However, high

Get Started

High-Frequency vs. Low-Frequency Inverters

Inverters are crucial components in solar power systems, uninterruptible power supplies (UPS), and other electrical systems. Their job is to convert DC (direct current) power into AC

Get Started

12VDC 400W to 2000W High Frequency Converter for RV

Jul 25, 2025 · 12VDC 400W to 2000W High Frequency Converter for RV, Find Details and Price about Inverter High Frequency Inverter from 12VDC 400W to 2000W High Frequency

Get Started

High frequency inverter vs low frequency

Nov 2, 2023 · The high-frequency inverter first uses high-frequency DC/DC conversion technology to invert low-voltage direct current into high-frequency

Get Started

4KW 5KW 6KW 7KW 8KW Industrial Frequency Inverter

Aug 10, 2025 · High quality 4KW 5KW 6KW 7KW 8KW Industrial Frequency Inverter is offered by China manufacturer Jingxing. Buy Industrial Frequency Inverter which is of high quality directly

Get Started

9 Best RV Inverters – Pure Sine Wave Power

May 31, 2023 · The Energizer RV inverter product picture Buy from Amazon This 3,000W power inverter by Energizer has a high 6,000W surge power, making

Get Started

Medium frequency and high frequency DC inverter

Apr 2, 2025 · Due to their different frequency characteristics, medium-frequency DC inverter transformers and high-frequency DC inverter transformers are suitable for industrial heating,

Get Started

Frequency Inverter Basic: Introduction, Functions

Dec 11, 2023 · Function of Frequency Inverter Speed Regulation Function: Frequency inverters can change the speed of the motor by adjusting the

Get Started

Power Frequency Inverter vs High-Frequency Inverter

Nov 14, 2024 · If you are looking for an inverter for fixed power stations, precision instruments, or other related fields, then go with power-frequency inverters. However, a high-frequency

Get Started

Should RVs choose power frequency inverters or high frequency inverters?

Sep 13, 2021 · Consumers are always entangled between the industrial frequency inverter and the high frequency inverter when purchasing the RV inverter. What is the difference between

Get Started

Should RVs choose power frequency inverters or high frequency inverters?

Sep 13, 2021 · The power frequency inverter first inverts the DC power into a power frequency low-voltage AC power, and then boosts it into a 220V, 50Hz AC power for the load through a

Get Started

High Capacity Industrial Power Inverter

1 day ago · We are best suppliers of industrial power inverters with a 5KVA to 600KVA range, IGBT with microcontroller-based, highly useful for industrial &

Get Started

Low Frequency vs High Frequency Inverters:

4 days ago · A low-frequency inverter is a superior choice if you need an inverter for heavy-duty applications that require handling high surge loads—such as

Get Started

High Frequency Inverter vs Low Frequency

Aug 18, 2025 · Discover the disparities between high frequency inverter vs low frequency inverter in this concise article, aiding your decision-making process.

Get Started

What is the difference between a high frequency

Apr 25, 2024 · Since the high-frequency inverter uses small-sized, lightweight high-frequency magnetic core materials, the power density of the circuit is

Get Started

The difference between industrial frequency inverter and high frequency

Jan 6, 2021 · The high-frequency inverter first uses high-frequency DC/DC conversion technology to invert low-voltage direct current into high-frequency and low-voltage alternating current;

Get Started

The difference between high frequency inverter

May 15, 2024 · Low frequency inverters, on the other hand, may be more suitable for applications with inductive loads or where a higher level of harmonic

Get Started

6 FAQs about [Industrial frequency and high frequency inverter for RV]

What is a high frequency inverter?

A high frequency inverter refers to an inverter that performs inversion at this higher frequency range. The selection for frequency range of the inverter will be influenced by the application needs and specific requirements. Low frequency inverters are usually used in larger power applications such as home power systems and industrial power, etc.

What is the difference between low frequency and high frequency inverters?

Low-frequency Inverters are designed to handle high-surge loads, typically 2-5 times their rated power output. This makes them perfect for refrigerators, compressors, or air conditioners requiring extra power during startup. High-frequency inverters typically have 1.5-2 times their rated power, which limits their surge capacity.

How does a low frequency inverter work?

The low frequency inverter first inverts the DC power into low-frequency low-voltage AC power, and then boosts it through the low frequency transformer into 220V, 50Hz AC power for the load. Features of low frequency inverter:

Why are high frequency inverters more efficient?

In contrast, high-frequency inverters can use smaller-sized and lighter-weight components due to their use of higher frequencies, resulting in smaller overall size and weight. Efficiency: Since the high frequency inverter uses high-frequency switches for inversion, its switching loss is relatively small, so it has higher conversion efficiency.

Should you buy a high-frequency inverter?

On the other hand, if you’re looking for a portable solution for RVs, boats, or small solar setups, a high-frequency inverter is ideal for powering lighter loads, such as laptops, LED lights, and small electronics.

What are the different types of industrial grade power inverters?

There are two distinct types of industrial grade power inverters distinguished by the size of their transformers, and the switching speed of their transistors.

Related Articles

-

Household high frequency or industrial frequency inverter

Household high frequency or industrial frequency inverter

-

High frequency inverter for RV

High frequency inverter for RV

-

The difference between inverter high frequency and industrial frequency

The difference between inverter high frequency and industrial frequency

-

Industrial frequency machine and high frequency machine inverter

Industrial frequency machine and high frequency machine inverter

-

High frequency power supply and industrial frequency inverter

High frequency power supply and industrial frequency inverter

-

High frequency inverter produces 1200v

High frequency inverter produces 1200v

-

Inverter high frequency vibration

Inverter high frequency vibration

-

High frequency inverter front stage output

High frequency inverter front stage output

-

High frequency inverter has high temperature

High frequency inverter has high temperature

-

Africa No 8 High Frequency Inverter

Africa No 8 High Frequency Inverter

Commercial & Industrial Solar Storage Market Growth

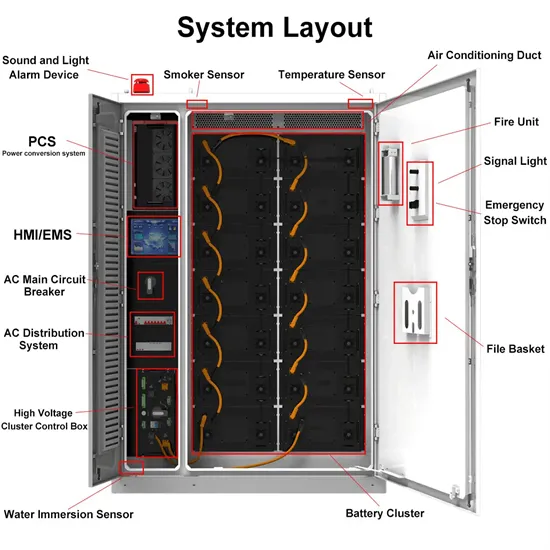

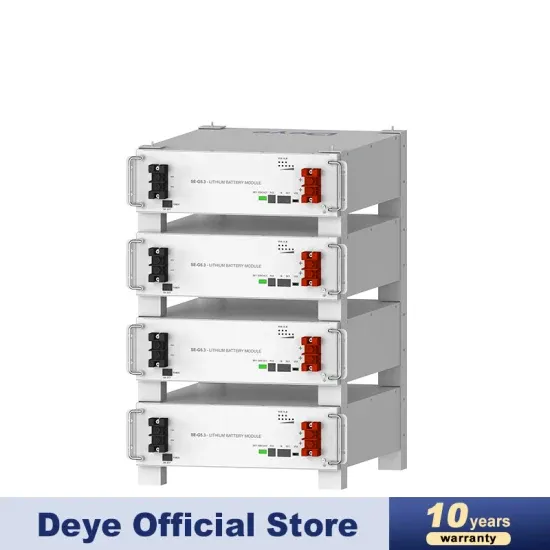

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.