Charging and discharging of lead acid battery

Aug 6, 2024 · Summarize: The charging and discharging of lead-acid batteries need daily maintenance, pay attention to the charger specifications, charging environment, charging

Get Started

Understanding the Discharge Characteristics of

4 days ago · 11 月.23,2023 Lead-acid batteries, known for their reliability and versatility, exhibit distinct discharge characteristics that impact their

Get Started

Lead-Acid Battery Lifetime Estimation using

Mar 10, 2022 · Abstract Determining battery lifetime used in cellular base stations is crucial for mobile operators to maintain availability and quality of service as

Get Started

BU-501: Basics about Discharging

Oct 27, 2021 · Table 4: Nominal and recommended end-of-discharge voltages under normal and heavy load The lower end-of-discharge voltage on a high

Get Started

How to Charge a Lead Acid Battery: A Complete Guide

Feb 13, 2025 · The correct charging method selection for a Keheng sealed lead-acid battery depends on its intended use (cycling or float), economic factors, charging time, expected

Get Started

The Prediction of Capacity Trajectory for Lead Acid

Oct 6, 2021 · Abstract: In this paper, a method of capacity trajectory prediction for lead-acid battery, based on the steep drop curve of discharge voltage and improved Gaussian process

Get Started

Full life cycle assessment of an industrial lead–acid battery

Jun 5, 2025 · From an LCA point of view, while the LAB is potentially the better environmental choice for a data centre (with few charge/discharge cycles), an LFP battery should be used in

Get Started

Lead-Acid Battery Basics

Sep 13, 2023 · For each discharge/charge cycle, some sulfate remains on the electrodes. This is the primary factor that limits battery lifetime. Deep-cycle

Get Started

BU-808: How to Prolong Lithium-based Batteries

Oct 11, 2023 · Table 2 estimates the number of discharge/charge cycles Li-ion can deliver at various DoD levels before the battery capacity drops to 70

Get Started

TECHNICAL MANUAL SEALED LEAD-ACID BATTERIES

Oct 24, 2019 · Cyclic Use: The number of charge/discharge cycles depends on the capacity taken from the battery (a function of discharge rate and depth of discharge), operating temperature

Get Started

Performance Testing Lead-Acid Stationary Batteries:

Jan 10, 2023 · Generally speaking, vented flat plate lead calcium batteries can deliver approximately 50 cycles to a depth of discharge of approximately 80%. Depending upon the

Get Started

How to Calculate the time of Charging and

Dec 25, 2011 · How do I calculate the approximated time for the Charging and Discharging of the battery? Is there any equation available for the purpose? If

Get Started

Base station lead-acid battery charge and discharge times

Example 1: Lead Acid Battery. Let''''s assume you have the following setup: Battery capacity: 100Ah; Charging current: 10A; Battery type: Lead acid; To calculate charging time using

Get Started

TECHNICAL MANUAL SEALED LEAD-ACID BATTERIES

Oct 24, 2019 · Long Shelf Life A low self-discharge rate, up to approximately 3% per month, may allow storage of fully charged batteries for up to a year, depending on storage temperatures,

Get Started

How Low Can A Lead Acid Battery Go? Minimum Discharge

Mar 13, 2025 · A lead acid battery should not go below 10.8 volts when under load. Going below this discharge level can cause battery damage. To ensure good battery health and longevity,

Get Started

LONG-DURATION DUTY CYCLE REQUIREMENTS: IS THE

Jul 26, 2019 · Stationary lead-acid batteries remain the economical first choice for standby power batteries with discharge times between 15min and 8h; they have been well proven in practice.

Get Started

電池技術手冊

May 4, 2019 · 3.1 Battery Capacity Battery capacity is expressed as ampere-hour (Ah), which is the product of discharged current and the discharged time in hours (A*h). Discharge rate is

Get Started

Microsoft Word

Oct 31, 2021 · Discharge capacity, power and energy requirements of the battery subsystem can be delivered by a variety of lead-acid batteries during early charge-discharge cycles of the

Get Started

Lead-acid battery charging and discharging

Apr 23, 2024 · 1. Charge and discharge characteristics The characteristics of Lead-acid battery during charging and discharging, including the change of

Get Started

Battery Sizing

Apr 8, 2012 · type of battery (sealed, vented, lead acid, NiCad, etc.) expected life of the battery usage of the batter (number of charge/discharge cycles)

Get Started

BU-403: Charging Lead Acid

Dec 8, 2023 · The constant-current charge applies the bulk of the charge and takes up roughly half of the required charge time; the topping charge

Get Started

Comparison of different lead–acid battery lifetime prediction models

Feb 15, 2014 · Lifetime estimation of lead–acid batteries in stand-alone photovoltaic (PV) systems is a complex task because it depends on the operating conditions of the batteries. In many

Get Started

LONG-DURATION DUTY CYCLE REQUIREMENTS: IS THE

Jul 26, 2019 · INTRODUCTION Stationary lead-acid batteries remain the economical first choice for standby power batteries with discharge times between 15min and 8h; they have been well

Get Started

Battery testing guide

Jul 20, 2011 · The acid is depleted upon discharge and regenerated upon recharge. Hydrogen and oxygen form during discharge and float charging (because float charging is counteracting

Get Started

BU-201: How does the Lead Acid Battery Work?

Depending on the depth of discharge, lead acid for deep-cycle applications provides 200 to 300 discharge/charge cycles. The primary reasons for its

Get Started

Lead-Acid Battery Lifetime Estimation using

Mar 10, 2022 · Determining battery lifetime used in cellular base stations is crucial for mobile operators to maintain availability and quality of service as well as to

Get Started

Battery Discharge Testing: Implementing NERC

Jan 10, 2023 · With the approval of NERC PRC 005-2 "Protection System Maintenance" standard, entities falling under its umbrella will have to test batteries per its requirements. The paper

Get Started

Detailed Explanation of the Charging and Discharging

Dec 16, 2024 · Deep cycle batteries are widely used in various applications where reliable and long-lasting power storage is required. Understanding the charging and discharging principles

Get Started

The Dos and Don''ts of Charging Sealed Lead

The Dos and Don''ts of Charging Lead-Acid Batteries Find out all the dos and don''ts when it comes to charging and taking care of lead-acid batteries to

Get Started

Battery Charge and Discharge Rate Calculator: C

Mar 3, 2023 · Use our battery charge and discharge rate calculator to find out the battery charge and discharge rate in amps. Convert c-rating in amps.

Get Started

LEAD ACID BATTERIES

Aug 2, 2021 · Lead acid batteries are heavy and less durable than nickel (Ni) and lithium (Li) based systems when deep cycled or discharged (using most of their capacity). Lead acid

Get Started

6 FAQs about [Base station lead-acid battery charge and discharge times]

When should a lead acid battery be fully charged?

Periodically fully charging a lead–acid battery is essential to maintain capacity and usability. In traditional UPS or cyclic use, full recharge normally occurs following any discharge. This is in contrast to partial-state-of-charge use. In this use case, multiple shallow cycles of less than 50% of the battery capacity occur before a full charge.

How to charge a lead-acid battery?

The charging method of lead-acid battery needs to choose different charging equipment according to different situations, usually the charging method of lead-acid battery has fixed-current charging, fixed-voltage charging, rapid charging (pulse charging) and so on, and it is recommended to use pulse charging, which is described as follows.

How to care for lead-acid batteries?

The charging and discharging of lead-acid batteries need daily maintenance, pay attention to the charger specifications, charging environment, charging voltage when charging, and avoid deep discharge when discharging, so that the lead-acid batteries can be used for a longer period of time.

Why do lead-acid batteries need to be discharged daily?

Diesel-electric power is expensive, so the battery is discharged daily to about 50% DOD. In developed countries, grid stability becomes an issue, especially if much of the electric power is generated by solar or wind energy. As a result, load levelling in distributed sites has become a new challenge for lead-acid batteries.

Why does a lead-acid battery take longer to charge?

The factor limiting the charging speed of lead–acid batteries is often the dissolution of the sulphate crystals in the negative active mass. This greater resistance means that the cell reaches the constant-voltage stage at a lower state of charge. As such, the cell needs longer in the constant-voltage stage to reach a full state of charge.

Why is recharging a lead-acid battery important?

The loss in capacity is particularly severe at high current rates of discharge and low temperature. At high temperatures, the gain in capacity is highest at the highest current rates of discharge. Proper recharging between discharges is an important key to obtaining optimum life from any lead-acid battery.

Related Articles

-

How to build a lead-acid battery for a wireless communication base station

How to build a lead-acid battery for a wireless communication base station

-

How to charge the maintenance-free battery of the base station

How to charge the maintenance-free battery of the base station

-

5g communication base station lead-acid battery construction

5g communication base station lead-acid battery construction

-

Chad 5g communication base station lead-acid battery company

Chad 5g communication base station lead-acid battery company

-

Communication base station lead-acid battery wind power generation installation

Communication base station lead-acid battery wind power generation installation

-

Greece Telecommunication Base Station Lead-acid Battery Project

Greece Telecommunication Base Station Lead-acid Battery Project

-

Base station lead-acid battery heating up when charging

Base station lead-acid battery heating up when charging

-

Vientiane Communication Base Station Lead-acid Battery Photovoltaic Power Generation External Machine Cooling

Vientiane Communication Base Station Lead-acid Battery Photovoltaic Power Generation External Machine Cooling

-

How to charge the base station lithium battery

How to charge the base station lithium battery

-

Base station lead-acid battery capacity

Base station lead-acid battery capacity

Commercial & Industrial Solar Storage Market Growth

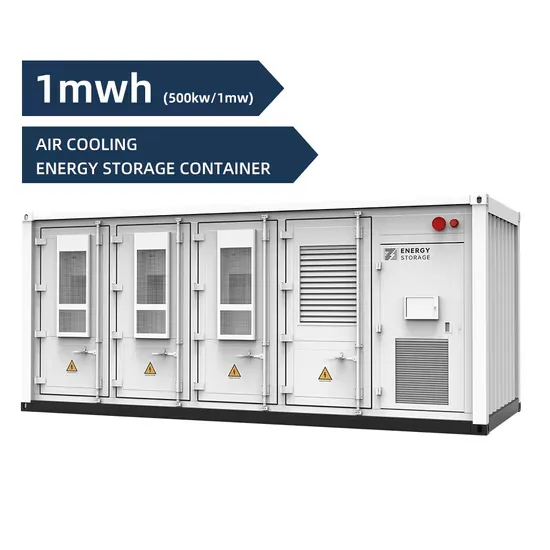

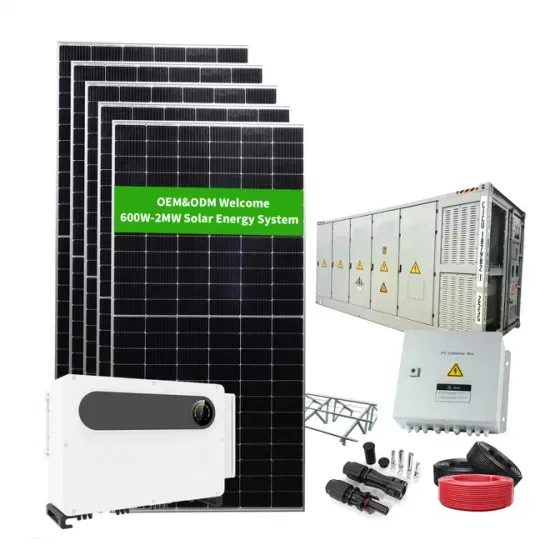

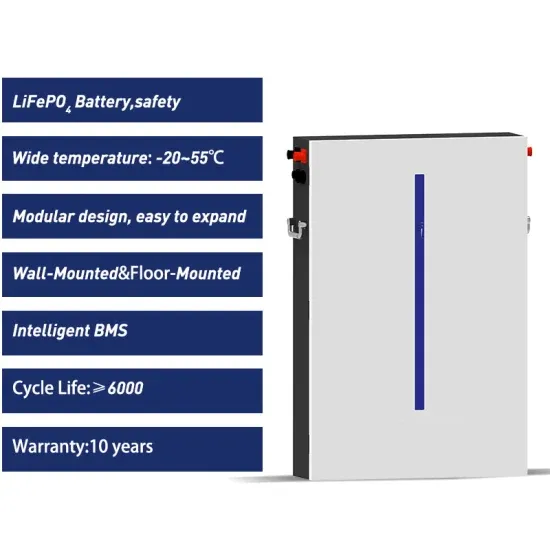

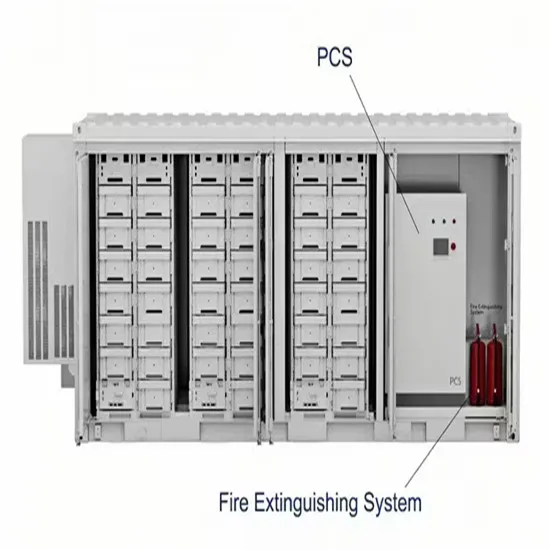

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.