High-Frequency Inverter: How They Work and

3 days ago · A high-frequency inverter is an electrical device that converts direct current (DC) into alternating current (AC) at a high switching frequency,

Get Started

High Frequency Inverter Circuit

Nov 19, 2019 · A high frequency inverter circuit is an electronic circuit that allows for the conversion of DC electricity into AC power with a high frequency, usually around 60 Hz or more.

Get Started

Working principle of EDECOA high frequency sine wave inverter

Aug 21, 2024 · Working principle of EDECOA high frequency sine wave inverter According to the waveform modulation mode of the inverter itself, it can be divided into square wave inverter,

Get Started

Inverters High or Low Frequency ? | DIY Solar Power Forum

Apr 15, 2020 · Low-frequency inverters use high-speed switches to invert (or change) the DC to AC, but drive these switches at the same frequency as the AC sine wave which is 60 Hz (60

Get Started

Inverter design using high frequency

Feb 27, 2021 · In which we are developing an inverter which is to be light in weight, compact and highly energy efficient. This can possible with the help of High Frequency Inverter; hence we

Get Started

Design and Development of High Frequency Inverter for

In these applications, the optimal converter design is essential for handling the high power and frequency operation. In this paper, Simulation & Hardware development of High frequency

Get Started

What is a High-Frequency Power Inverter?

1 day ago · Introduction A power inverter converts DC power into AC power for operating AC loads and equipment. High-frequency power inverters utilize

Get Started

The difference between low frequency inverter

Dec 22, 2021 · The advantages of high frequency inverter: light weight, small size, small standby power and high efficiency. The disadvantage is that the circuit is

Get Started

What is a High-Frequency Power Inverter?

May 14, 2024 · There are two definitions of fundamental frequency: a. The frequency corresponding to the maximum output voltage of the inverter is

Get Started

Detailed explanation of the working principle of high frequency inverter

High-frequency inverter electrical appliances are a kind of switching equipment used in the industrial field. What is the working principle of high-frequency inverters?

Get Started

Differences between high and low frequency

Apr 25, 2024 · Since the high-frequency inverter uses small-sized, lightweight high-frequency magnetic core materials, the power density of the circuit is

Get Started

Voltage Fed Full Bridge DC-DC & DC-AC Converter High

Apr 1, 2023 · ABSTRACT The High-Frequency Inverter is mainly used today in uninterruptible power supply systems, AC motor drives, induction heating and renewable energy source

Get Started

High frequency inverter vs low frequency

Nov 2, 2023 · The high-frequency inverter first uses high-frequency DC/DC conversion technology to invert low-voltage direct current into high-frequency

Get Started

Frequency Inverter | inverter

0.4kw frequency inverter for sale, convert single phase to three phase for AC motor speed controls, rated current 3A, input frequency 50Hz~60Hz, and output frequency 0Hz~1000Hz.

Get Started

A Single Stage ZVS-PWM Inverter for Induction Heating

Oct 27, 2016 · This one-stage high frequency inverter which is composed of single phase diode bridge rectifier, non-smoothing filter, boost-active clamp bridge type zero voltage soft switching

Get Started

High Frequency Inverter vs Low Frequency

Aug 18, 2025 · Discover the disparities between high frequency inverter vs low frequency inverter in this concise article, aiding your decision-making process.

Get Started

What is a Frequency Inverter? A Complete Guide to How It

4 days ago · Curious about what a frequency inverter is? This guide explains how VFDs work, their key benefits like energy savings, and their applications in simple terms. Learn everything

Get Started

How to Distinguish High Frequency Inverter and Low Frequency Inverter

Apr 11, 2024 · Low frequency inverters produce less electromagnetic interference, but can only produce lower AC power frequencies, while high frequency inverters can produce higher

Get Started

CSM_Inverter_TG_E_1_1

Mar 27, 2016 · A high-frequency filter that is connected to the power supply side or load side of an inverter to absorb noise that is generated in an inverter when a power device switches.

Get Started

Mastering Inverter Switching Frequencies: A

Apr 25, 2024 · Explore the intricate dance of inverter switching frequencies to optimize energy flow. Master the rhythms of power electronics with our

Get Started

The difference between a high and low frequency inverter

Understanding the differences between a high and low frequency inverter helps you make informed decisions. High frequency inverters offer compactness and efficiency, making them

Get Started

Working principle of EDECOA high frequency

Aug 21, 2024 · Working principle of EDECOA high frequency sine wave inverter According to the waveform modulation mode of the inverter itself, it can be

Get Started

Nine-level high-frequency inverter

Aug 7, 2024 · At present, to generate HFAC output, existing inverters mainly use a DC/AC inverter to produce high-frequency square wave or high-frequency quasi-square wave output,

Get Started

Advantages of High-Frequency Inverters in

In the world of electrical engineering and power electronics, high-frequency inverters play a crucial role in various applications, offering a wide array of

Get Started

High Frequency Transformer: |Working, Design & Application|

A high frequency transformer is a type of transformer that operates at frequencies higher than the standard power frequency of 50/60Hz ( few kilohertz to megahertz).

Get Started

Understanding the Working Principle of High

Mar 1, 2024 · In the realm of modern industrial machinery and automation, efficiency and precision are paramount. One technology that plays a crucial

Get Started

High Frequency Inverter vs low Frequency Inverter

Conclusion In conclusion, the choice between high-frequency and low-frequency inverters depends largely on the specific needs of the application. High-frequency inverters offer the

Get Started

High frequency vs low frequency pure sine wave

Aug 16, 2016 · The Sigineer low-frequency inverters can output a peak 300% surge power for 20 seconds, while high-frequency inverters can deliver 200%

Get Started

High Frequency Transformer: Working Principle,

May 16, 2023 · It also works as an inverter power transformer in a high-frequency inverter power supply and a high-frequency inverter welding machine. The

Get Started

How Does a Frequency Inverter Work?

Dec 13, 2023 · Input Power: The frequency inverter receives AC power through the input rectifier and converts it to DC power. The intermediate DC link

Get Started

Difference Between High and Low Frequency Inverter

Apr 30, 2025 · Understand the difference between high and low frequency inverters (lf vs hf inverter) and what are the main features of Xindun Power''s high frequency inverters?

Get Started

Analysis of the Working Principle and Application of High Voltage Inverter

May 15, 2024 · The working principle of high voltage inverter is to control the speed of motor by changing the frequency of alternating current (AC), MICNO high voltage inverter adopts

Get Started

6 FAQs about [The working frequency of high frequency inverter]

What are the advantages and disadvantages of high frequency inverters?

Benefits of High-Frequency Inverters: Uncover the advantages offered by high-frequency operation, such as reduced size, improved efficiency, and noise suppression. Topologies of High-Frequency Inverters: Examine the different topologies used in high-frequency inverters, including half-bridge, full-bridge, and multilevel.

What determines the output frequency of a high-frequency inverter?

The output frequency depends on how fast the switches cycle on and off. Common high-frequency inverter circuit configurations include: Key design factors for high-frequency inverters: Switching frequency – Higher frequency allows smaller filter components but increases losses. Optimize based on tradeoffs.

What is a high-frequency inverter?

In the realm of power electronics, the advent of high-frequency inverters has revolutionized the landscape. These enigmatic devices possess the uncanny ability to transform direct current (DC) into alternating current (AC) at remarkably high frequencies, unlocking a world of boundless possibilities.

How does a high frequency inverter work?

The inverter bridge contains power switches like IGBTs or MOSFETs. The switches turn on and off at high speed to generate high-frequency pulses. An LC filter smoothens the pulses into sinewave AC output. The output frequency depends on how fast the switches cycle on and off. Common high-frequency inverter circuit configurations include:

What are common high-frequency inverter circuit configurations?

Common high-frequency inverter circuit configurations include: Key design factors for high-frequency inverters: Switching frequency – Higher frequency allows smaller filter components but increases losses. Optimize based on tradeoffs. Filter components – Smaller inductors and capacitors possible at high frequencies. Balance size versus performance.

What are the topologies of high-frequency inverters?

Topologies of High-Frequency Inverters: Examine the different topologies used in high-frequency inverters, including half-bridge, full-bridge, and multilevel. Modulation Techniques: Discover various modulation techniques employed in high-frequency inverters to control the output AC waveform.

Related Articles

-

Imported high frequency inverter manufacturers

Imported high frequency inverter manufacturers

-

Inverter from high frequency to low frequency

Inverter from high frequency to low frequency

-

High frequency inverter output efficiency

High frequency inverter output efficiency

-

High frequency inverter has high temperature

High frequency inverter has high temperature

-

Belgian high frequency inverter price

Belgian high frequency inverter price

-

Africa No 8 High Frequency Inverter

Africa No 8 High Frequency Inverter

-

The difference between inverter high frequency and industrial frequency

The difference between inverter high frequency and industrial frequency

-

High frequency pulse frequency inverter

High frequency pulse frequency inverter

-

High frequency inverter life

High frequency inverter life

-

High frequency inverter in Douala Cameroon

High frequency inverter in Douala Cameroon

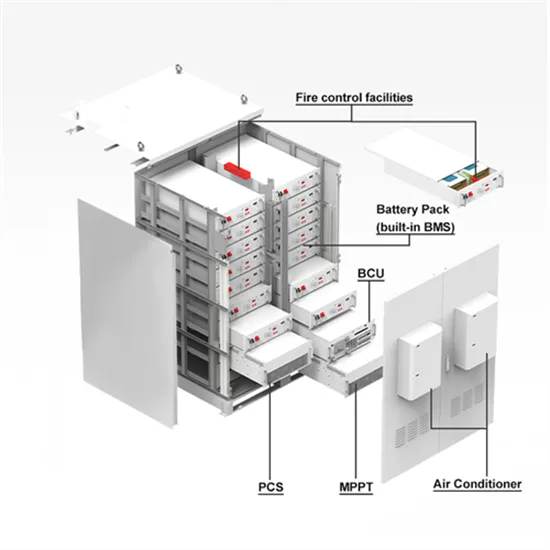

Commercial & Industrial Solar Storage Market Growth

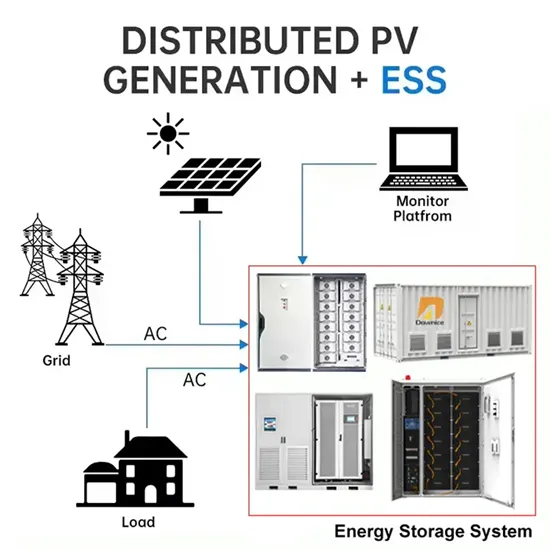

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.