KNOWLEDGE PAPER ON LITHIUM-ION BATTERY

Jan 22, 2024 · In order to deliver the required power and energy as per the application, it is necessary to assemble the individual Li-ion cells in series and parallel configuration to make

Get Started

Successful planning of battery cell production | Festo AE

Aug 28, 2024 · Battery cell production plays a decisive role in the development of modern energy storage solutions, especially for electric vehicles. Given the increasing demand for efficient

Get Started

Successful planning of battery cell production | Festo SG

Aug 28, 2024 · Battery cell production plays a decisive role in the development of modern energy storage solutions, especially for electric vehicles. Given the increasing demand for efficient

Get Started

How to Build a Lithium Ion Battery Pack: Expert Guide for

Aug 1, 2025 · Q4. What safety features should be integrated into a lithium-ion battery pack? Important safety features include thermal fuses, PTC devices, pressure relief valves, venting

Get Started

7 Key Steps in Battery PACK Manufacturing You Should Know

Jun 10, 2025 · The process of Battery PACK manufacturing plays a crucial role in ensuring that users have access to quality power sources that meet their needs. In this article, we''ll explore

Get Started

(PDF) BATTERY MODULE AND PACK ASSEMBLY

Feb 6, 2019 · Our second brochure on the subject "Assembly process of a battery module and battery pack" deals with both battery module assembly and

Get Started

Successful planning of battery cell production | Festo ID

Aug 28, 2024 · Battery cell production plays a decisive role in the development of modern energy storage solutions, especially for electric vehicles. Given the increasing demand for efficient

Get Started

Successful planning of battery cell production | Festo NZ

Aug 28, 2024 · Battery cell production plays a decisive role in the development of modern energy storage solutions, especially for electric vehicles. Given the increasing demand for efficient

Get Started

Battery safety: Machine learning-based prognostics

May 1, 2024 · Given these risks, UK legislators are considering classifying lithium-ion battery storage sites as "hazardous", enforcing stringent fire safety and planning controls [23]. For

Get Started

What is a Battery Pack? [Definition] | Zitara Glossary

Aug 12, 2025 · A battery pack is a collection of battery cells packaged into an application-specific format. These can be as small as a single cell or as large as thousands of cells arranged in

Get Started

Understanding aging mechanisms in lithium-ion battery

Mar 15, 2015 · However, engineering practice indicates that battery packs always fade more critically than cells. We investigate the evolution of battery pack capacity loss by analyzing cell

Get Started

Handbook On Lithium Battery Pack Design

Oct 30, 2023 · Battery pack connectors are usually specified by our customer to ensure the battery pack is attached correctly to the device with the right polarity. Fitting a connector also

Get Started

The Ultimate Guide to 18650 Battery Packs:

Apr 18, 2025 · The Ultimate Guide to 18650 Battery Packs: Design, Benefits, and Charging Best Practices Introduction In the rapidly evolving landscape of

Get Started

Successful planning of battery cell production | Festo CH

Aug 28, 2024 · Battery cell production plays a decisive role in the development of modern energy storage solutions, especially for electric vehicles. Given the increasing demand for efficient

Get Started

Battery Pack Design: Efficient & Safe Energy

Mar 15, 2025 · In this post, you''ll learn the fundamentals of battery pack design. We''ll explore its components, configurations, safety measures, and advanced

Get Started

Designing a Lithium-Ion Battery Pack: A Comprehensive Guide

Feb 15, 2025 · In this blog post, we will delve into the key steps and considerations involved in designing a lithium-ion battery pack. Before diving into the design process, it''s crucial to

Get Started

Successful planning of battery cell production | Festo MY

Aug 28, 2024 · Battery cell production plays a decisive role in the development of modern energy storage solutions, especially for electric vehicles. Given the increasing demand for efficient

Get Started

(PDF) Material selection and assembly method

Jan 1, 2018 · Therefore, this work presents Decision Matrix, which can aid in the decision-making process of component materials and assembly methods for a

Get Started

Design approaches for Li-ion battery packs: A review

Dec 20, 2023 · The paper aims to investigate what has been achieved in the last twenty years to understand current and future trends when designing battery packs. The goal is to analyze the

Get Started

The Fundamentals of Battery Pack and Module

Apr 19, 2024 · With the continued global growth of electric vehicles, a new opportunity for the battery manufacturers is emerging: developing EV batteries

Get Started

A Comprehensive Roadmap for Successful Battery Energy

Jun 10, 2025 · Successful execution of BESS projects requires a systematic methodology that coordinates multiple disciplines, stakeholders, and technical requirements. The following

Get Started

What''s holding back battery energy storage

Oct 30, 2024 · Charles Deacon, Managing Director at Eclipse Power Solutions, explores how to get more battery energy storage connected to the grid.

Get Started

Successful planning of battery cell production | Festo LT

Jochen Luik: Starting out in the battery market offers enormous potential, especially given the increasing demand for energy storage solutions for electric cars. Battery cell production opens

Get Started

Lithium-ion Battery Pack Manufacturing Process

Jul 28, 2023 · In this article, we will explore the world of battery packs, including how engineers evaluate and design custom solutions, the step-by-step

Get Started

Successful planning of battery cell production | Festo IE

Leveraging demand Mr Luik, what makes entry into the world of battery cell production so exciting? Jochen Luik: Starting out in the battery market offers enormous potential, especially

Get Started

(PDF) Mechanical Design of Battery Pack

Aug 16, 2023 · The battery pack is enclosed in a structurally optimized casing to withstand external conditions. Efficient electric connections are established

Get Started

An End-To-End Methodology for Battery Pack Design

Oct 6, 2021 · Battery Pack Thermal Management for our Electric Cargo 2-wheeler was kept in prime focus considering great chances of thermal runaway in Lithium-Ion battery pack. An

Get Started

Successful planning of battery cell production | Festo IL

Aug 28, 2024 · Battery cell production plays a decisive role in the development of modern energy storage solutions, especially for electric vehicles. Given the increasing demand for efficient

Get Started

Successful planning of battery cell production | Festo FI

Aug 28, 2024 · Battery cell production plays a decisive role in the development of modern energy storage solutions, especially for electric vehicles. Given the increasing demand for efficient

Get Started

The Comprehensive Guide to Building a Battery Pack

Jun 19, 2025 · Whether you''re a hobbyist or a professional, mastering these steps will enable you to create efficient, safe, and durable battery packs tailored to your specific needs. 1.

Get Started

ESS''s Battery Pack Design Checklist: Your

Apr 26, 2025 · Streamline your battery pack development with ESS''s Battery Pack Design Checklist. Learn how to integrate safety, reliability and

Get Started

6 FAQs about [What should be done in the early planning of battery pack]

What is the first step in battery pack design?

The first and foundational step in battery pack design is a thorough analysis of requirements and specification definition. This initial phase sets the direction for the entire design process. During this stage, our engineering team works closely with clients to determine key parameters based on the specific application needs.

How do you design a custom lithium battery pack?

This blog post outlines the comprehensive design process we follow when developing custom lithium battery packs for our clients. The first and foundational step in battery pack design is a thorough analysis of requirements and specification definition. This initial phase sets the direction for the entire design process.

How to design a battery pack?

The dimensions of battery packs also require a design to space evaluation. The occupied volume of the pack should be suitable for the related car chassis. As previously mentioned in Section 1, CTP and CTC are two different strategies for packaging design. These approaches differ from the modular one.

How can battery packaging design improve battery safety?

A robust and strategic battery packaging design should also address these issues, including thermal runaway, vibration isolation, and crash safety at the cell and pack level. Therefore, battery safety needs to be evaluated using a multi-disciplinary approach.

How to design the crashworthiness of battery pack?

Zhu et al. implemented the crashworthiness design of battery pack through numerical simulations with machine learning approach. The design constitute multiple layered porous with homogenous materials and subjected to the impact of cylindrical indenter.

How to design a battery system?

As Pumpel et al. suggested, it is necessary to consider space for the complete battery system during the early design phases. They defined essential design parameters such as component dimensions, wall thicknesses for module and pack housings, longitudinal and cross beams, air gaps, etc.

Related Articles

-

What do you need to build a lithium battery pack

What do you need to build a lithium battery pack

-

Fire protection planning for power battery pack factory

Fire protection planning for power battery pack factory

-

What equipment does a lithium battery pack require

What equipment does a lithium battery pack require

-

What is the battery trial production PACK

What is the battery trial production PACK

-

What brand of lithium battery pack do you use

What brand of lithium battery pack do you use

-

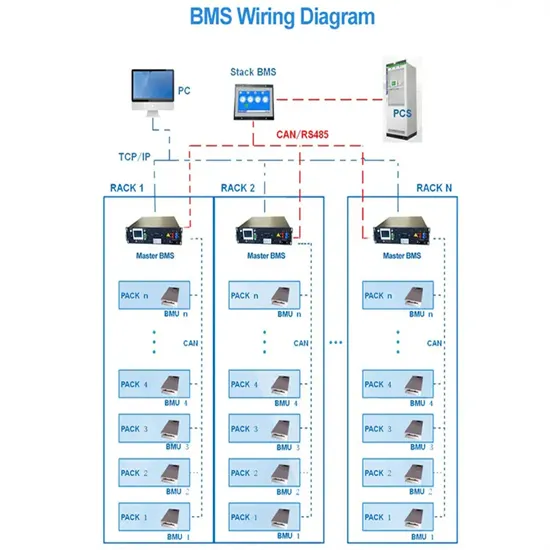

What does BMS battery pack mean

What does BMS battery pack mean

-

What nickel sheet is used in lithium battery pack

What nickel sheet is used in lithium battery pack

-

What are the new energy external battery cabinets included in

What are the new energy external battery cabinets included in

-

TCM lithium battery pack in Manchester UK

TCM lithium battery pack in Manchester UK

-

Kuwait power battery pack manufacturer

Kuwait power battery pack manufacturer

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.