Power Frequency Inverter vs High-Frequency Inverter

Nov 14, 2024 · These inverters are mostly found in applications with high volume or weight needs, such as aerospace, mobile power supplies, electric vehicles, or other fields. Power Frequency

Get Started

Advantages of High-Frequency Inverters in

In the world of electrical engineering and power electronics, high-frequency inverters play a crucial role in various applications, offering a wide array of

Get Started

Frequency inverters and motor starters from

Drive Electronics Frequency Inverters and Motor Starters Frequency Inverters and Motor Starters from NORD DRIVESYSTEMS are available as centralised

Get Started

Inversion Methods Explained: High Frequency vs Low Frequency

5 days ago · Understand the difference between high frequency and low frequency inverters with this quick article.

Get Started

Best Pure Sine Wave Inverters and Sustainable

Apr 22, 2025 · Discover how pure sine wave inverters work, why they''re essential for clean power, and which sustainable brands offer the best options for you.

Get Started

Frequency inverter for decentralised applications

May 22, 2024 · NORDAC FLEX, SK 200E series Frequency inverters are now essential components of electrical drive technology. They are used for a wide range of automation tasks

Get Started

An Intelligent Frequency Control Scheme for

Jan 22, 2025 · However, our current research aims on improving frequency control at Inverter station in HVDC transmission system by implementing

Get Started

Ultimate Guide to Choosing the Best Frequency Inverter for

Jun 14, 2025 · This ultimate guide will explore the industry standards associated with frequency inverters, highlight common problems encountered during selection, and offer insights into

Get Started

Inverters-FREQROL | Products | MITSUBISHI

Jan 31, 2025 · Inverters are variable frequency power supply units which can change the rotation speed of the three-phase induction motors easily and

Get Started

Differences between high and low frequency

Apr 25, 2024 · Inverters can generally be categorized based on their operating frequency into two main types: Low Frequency and High Frequency.

Get Started

FREQUENCY INVERTER

The inverters with the highest output frequency exceeding the power frequency are mostly small-capacity inverters. In the area above 50/60Hz, the output voltage is unchanged and is a

Get Started

Designing a SPWM Controlled High Voltage (HV) Three

May 12, 2023 · To transform the incoming Voltage level from PV arrays into pure sine AC voltage in accordance with the voltage and frequency of appropriately outputs, 220V and 50Hz

Get Started

A High Frequency Inverter for Variable Load Operation

Sep 27, 2018 · Inverters operating at high frequency (HF, 3-30MHz) are important to numerous industrial and commercial applications such as induction heating, plasma generation, and

Get Started

Induction motors fed by PWM frequency inverters

Mar 30, 2021 · This technical guide aims to clarify the main aspects concerning applications of low voltage (≤ 690 V) induction motors with static frequency inverters supply, for frames ≤ IEC 355

Get Started

Overspeed Motors

Jun 15, 2020 · Introduction Historically in the United States, with our 60 Hertz (Hz) alternating current electrical (AC) frequency, motors operate between minimum rotational speed (as low

Get Started

High Frequency Inverter vs Low Frequency

Aug 18, 2025 · High frequency solar inverter first through the high-frequency DC / DC conversion technology, low-voltage DC inverter for high-frequency low

Get Started

Inverter Specifications and Data Sheet

3 days ago · The article provides an overview of inverter functions, key specifications, and common features found in inverter systems, along with an

Get Started

SPWM GENERATOR BASED ON FPGA FOR HIGH

Feb 16, 2024 · The digital implementation of Sinusoidal Pulse Width Modulation (SPWM) generators have dominated over their counterparts based on analog circuits. Here an FPGA

Get Started

Technical comparison between Low Frequency

Aug 19, 2025 · What internal frequency the inverter circuits operate at – low frequency or high frequency (not to be confused with AC power output

Get Started

The highest frequency and basic frequency of

May 14, 2024 · 2. The maximum frequency is the maximum frequency that the inverter allows to output, expressed by fmax. Its specific meaning varies

Get Started

High frequency versus low inverters | DIY Solar Power Forum

Nov 18, 2019 · Thanks There are tons of details we could go into but it boils down to this: High-frequency inverters are generally lower-priced, lighter in weight, and can handle brief surges of

Get Started

A review on single-phase boost inverter technology for low

Feb 1, 2024 · In this regard inverters with less number of high-frequency switches produces lower power loss due to conduction and switching. From Table 7, it can be seen that differential

Get Started

Power Frequency Inverter vs. High Frequency

May 15, 2024 · High frequency inverter: High frequency inverters use high-frequency switching technology to chop DC power at high frequency through

Get Started

The highest frequency and basic frequency of the inverter

1. The maximum frequency is the maximum frequency that the inverter allows to output, expressed by fmax. Its specific meaning varies slightly depending on how the frequency is

Get Started

High Frequency Inverter vs low Frequency Inverter

Conclusion In conclusion, the choice between high-frequency and low-frequency inverters depends largely on the specific needs of the application. High-frequency inverters offer the

Get Started

Inverters Lineup | Mitsubishi Electric Automation

We offer a comprehensive line of factory automation solutions. Solutions include robots, automation platforms, sequence controllers, human-machine

Get Started

High frequency inverter vs low frequency

Nov 2, 2023 · This article compares high frequency inverter vs low frequency inverter from the aspects of working frequency, components, efficiency, size

Get Started

High Frequency 2500W Pure Sine Wave Inverter

Jun 3, 2025 · Choosing a trusted high frequency pure sine wave inverter producer, helping you expand your business in the power sector. 2500w pure

Get Started

6 FAQs about [Highest frequency inverter]

What are the advantages and disadvantages of high frequency inverters?

Benefits of High-Frequency Inverters: Uncover the advantages offered by high-frequency operation, such as reduced size, improved efficiency, and noise suppression. Topologies of High-Frequency Inverters: Examine the different topologies used in high-frequency inverters, including half-bridge, full-bridge, and multilevel.

Are high-frequency inverters a good choice?

Due to the use of high-frequency switching technology, high-frequency inverters have the advantages of small size, lightweight, and high efficiency, but they also have the problem of relatively poor output waveform quality.

What is the output frequency of a high-frequency inverter?

The output frequency of the high-frequency inverter is much higher than the power frequency, usually between a few kilohertz and tens of kilohertz.

What is the difference between high frequency and industrial frequency inverter?

The same power inverter industrial frequency inverter is far heavier than the high-frequency inverter, high frequency inverter is small in size, light in weight, high in efficiency, low no-load load, but can’t be connected to a full inductive load, and overload capacity is poor.

Are power frequency inverters good?

In contrast, power frequency inverters can maintain high efficiency and stability under heavy load or overload. Output waveform quality: The output waveform quality of power frequency inverters is usually better than that of high frequency inverters.

What determines a high or low frequency inverter?

Size and tolerances of the transistors used in the inversion process, and the speed at which they operate determines the classification of high or low frequency. The large majority of inverters available in the retail market are high frequency.

Related Articles

-

Highest conversion efficiency of household inverter

Highest conversion efficiency of household inverter

-

The highest communication base station inverter grid connection

The highest communication base station inverter grid connection

-

Sucre Electric Industrial Frequency Inverter Price

Sucre Electric Industrial Frequency Inverter Price

-

The inverter output high voltage frequency is too low

The inverter output high voltage frequency is too low

-

Is the photovoltaic power frequency inverter durable

Is the photovoltaic power frequency inverter durable

-

Rv outdoor use fast frequency sine inverter

Rv outdoor use fast frequency sine inverter

-

High frequency inverter output efficiency

High frequency inverter output efficiency

-

Huawei industrial frequency inverter 20kw

Huawei industrial frequency inverter 20kw

-

The difference between inverter high frequency and industrial frequency

The difference between inverter high frequency and industrial frequency

-

50 Hz high frequency inverter

50 Hz high frequency inverter

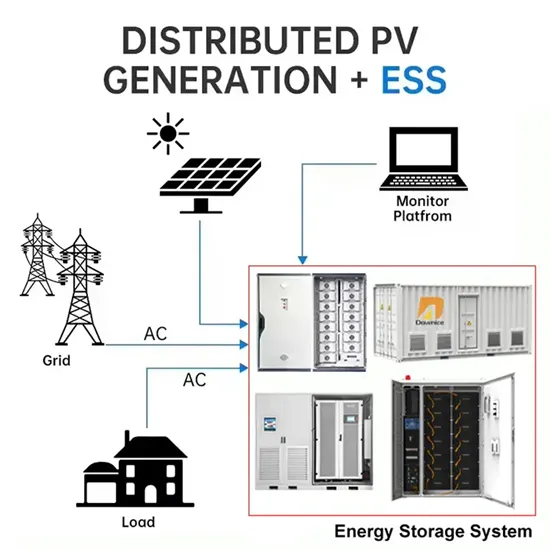

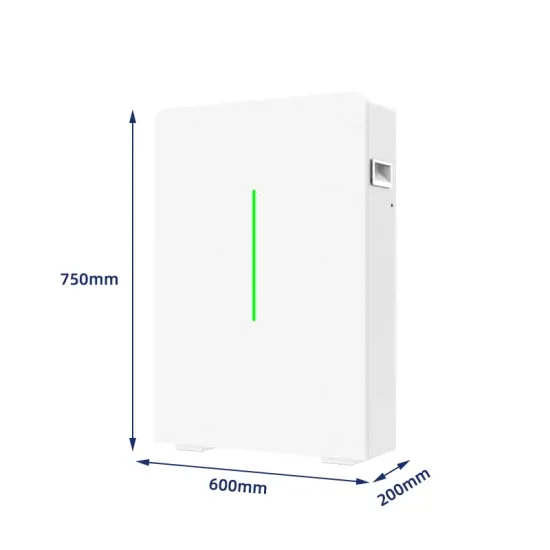

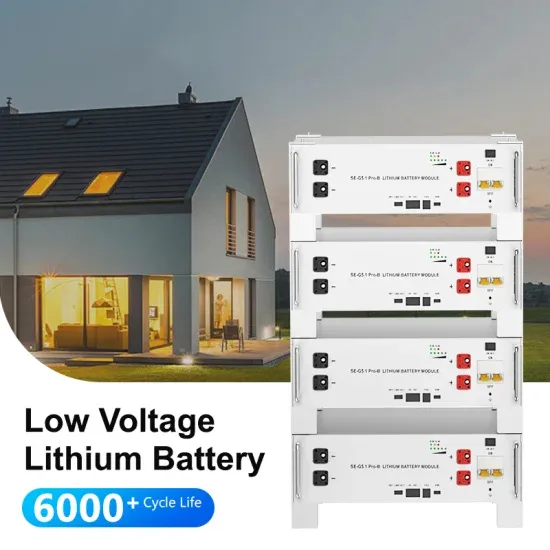

Commercial & Industrial Solar Storage Market Growth

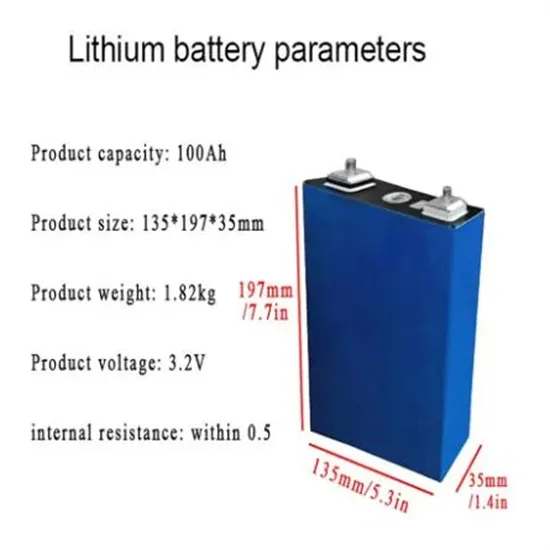

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.